Diluent composition and use thereof

A technology of composition and diluent, which is applied to photosensitive materials, instruments, and photoengraving processes of patterned surfaces for optomechanical equipment, etc. and other problems, to achieve the effect of excellent solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

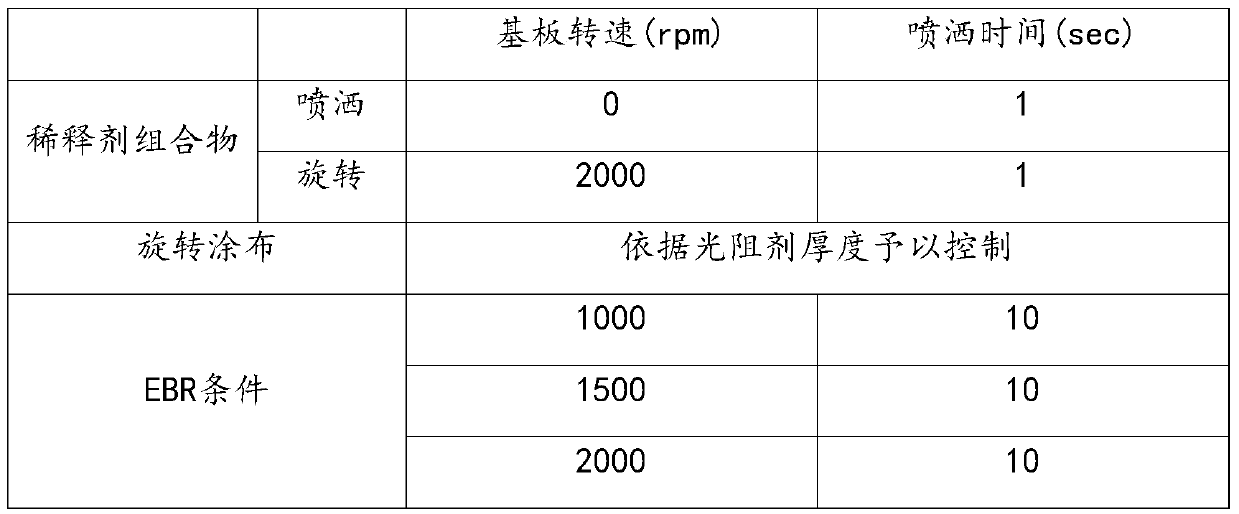

[0063] (Based on the evaluation of the edge ball removal performance of the photosensitive film type)

[0064] An 8-inch silicon oxide substrate was immersed in two hydrogen peroxide / sulfuric acid mixture baths for 5 minutes each, and then rinsed with ultrapure water. Next, the substrate was spin-dried in a spin drier, after which the diluent composition of Example 1 was spin-coated (about 1500 to 2500 rpm) on the substrate for reduced resist consumption (RRC) Coating pre-wetting process. Next, on the pre-wetted substrate, each photoresist described in Table 2 below was spin-coated (at about 300 rpm for about 3 seconds, and then at about 1000 to 2000 rpm for about 20 to 30 seconds) , to control to a predetermined thickness) on the substrate to form a photosensitive film with a corresponding thickness. In addition, using the thinner compositions of Examples 1 to 7 and Comparative Examples 1 to 10, a test for removing edge bulbs unnecessarily attached to the edge portion of th...

experiment example 2

[0075] (Evaluation of Photoresist Coating Uniformity)

[0076] Whether or not the photosensitive film was uniformly coated on the front side of the substrate was evaluated in the following manner.

[0077] An 8-inch silicon oxide substrate was immersed in two hydrogen peroxide / sulfuric acid mixture baths for 5 minutes each, and then rinsed with ultrapure water. Next, the substrate was spin-dried in a spin dryer (spin drier), and thereafter, the thinner compositions of Examples 1 to 7 and Comparative Examples 1 to 10 were spin-coated (about 1500 to 2500 rpm) on the substrate to reduce Pre-wet process for photoresist consuming (RRC) coating. At this time, each diluent composition is supplied from a pressurized container equipped with a pressure gauge (increased pressure of about 1.0 kgf), and is sprayed out through a nozzle (the flow rate of the composition is 10 to 20 cc / minute), and, The spraying time of the composition was controlled by the rotational speed of the substrate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com