Adsorbent concentrator for odorous compounds and VOCs

An organic compound and compound technology, applied in chemical instruments and methods, dispersed particle separation, separation methods, etc., can solve the problems of zeolite adsorption performance and service life, unusable, zeolite structure damage and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0049] Treatment of odorous compounds and VOCs (such as ammonia, hydrogen sulfide, CH 3 CHO and toluene, etc.) exhaust gas.

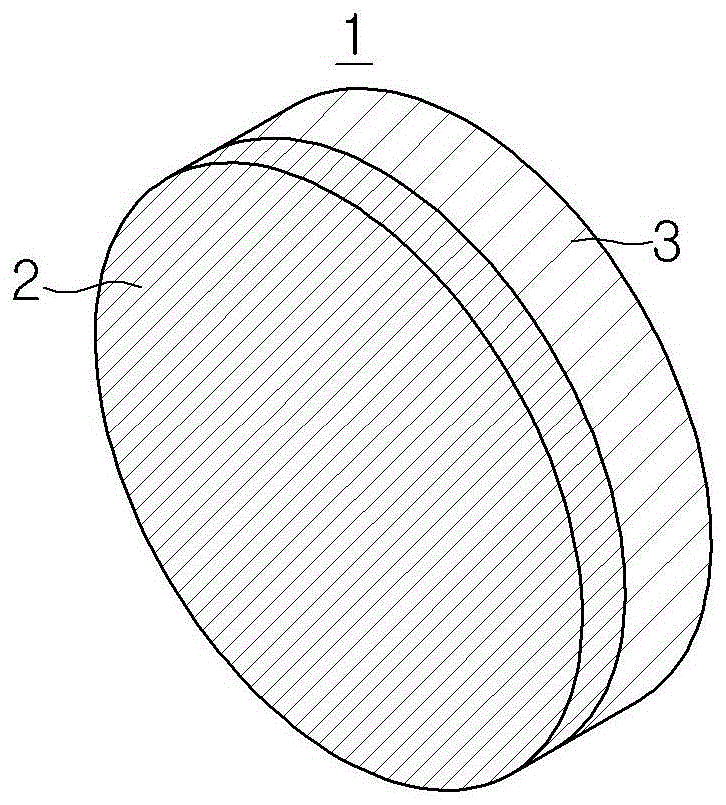

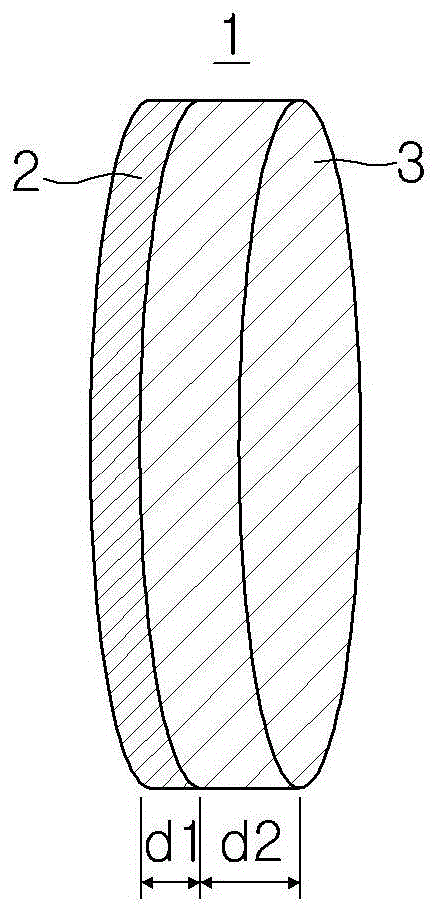

[0050] In this way, the front of the adsorption concentration unit ( figure 1 with figure 2 the first adsorption part) and the back ( figure 1 with figure 2 Each of the second adsorption members) was coated with the adsorption material in an amount of about 30 wt % based on the amount of the support. In particular, the frontage is at 380m 2 The specific surface area / g is coated with silicon oxide, activated carbon powder and synthetic zeolite in amounts of 40%, 10%, and 50%, respectively, as adsorption materials. The back is coated with synthetic zeolite in an amount of 100%. The thicknesses of the first adsorption member and the second adsorption member were set to 100 mm and 200 mm, respectively.

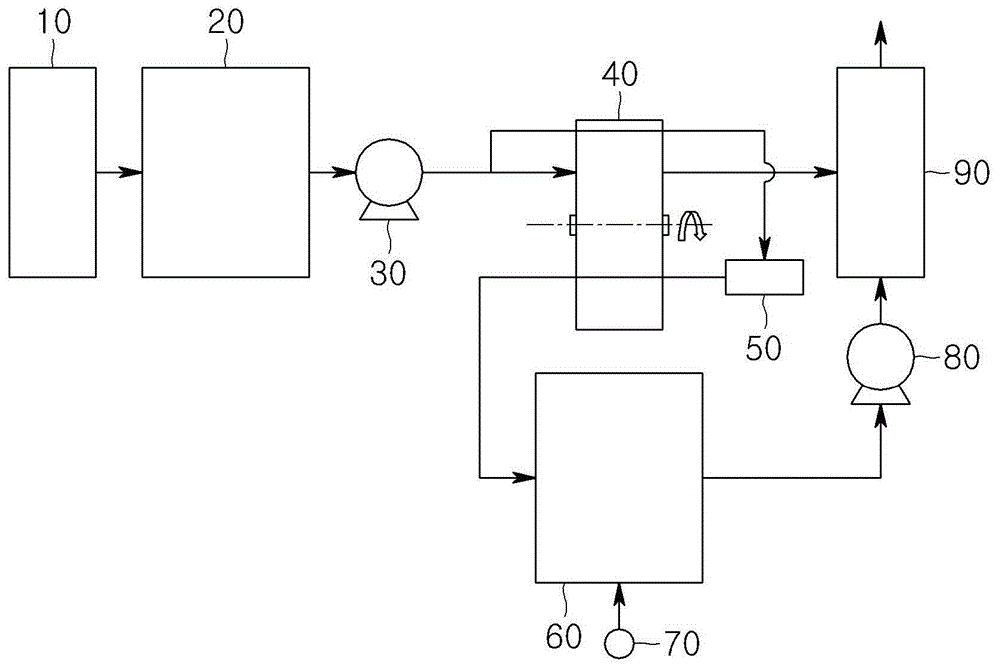

[0051] The treatment conditions are as follows: the rate at which exhaust gas passes through the adsorption concentration unit is 2m / s; the desorp...

example 2

[0062] Treatment of odorous compounds and VOCs (such as ammonia, hydrogen sulfide, CH 3 CHO, toluene, etc.) exhaust gas.

[0063] In this way, the front of the adsorption concentration unit ( figure 1 with figure 2 the first adsorption part) and the back ( figure 1 with figure 2 Each of the second adsorption members) was coated with the adsorption material in an amount of about 30 wt % based on the amount of the support. In particular, the frontage is at 380m 2 The specific surface area per g was coated with a mixture of silica and synthetic zeolite in an amount of 50% and 50%, respectively, as adsorption material. The back is coated with synthetic zeolite in an amount of 100%. The thicknesses of the first adsorption member and the second adsorption member were set to 100 mm and 200 mm, respectively.

[0064] The treatment conditions are as follows: the rate at which exhaust gas passes through the adsorption concentration unit is 2m / s; the desorption temperature of od...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com