Liquid-liquid heterogeneous mixing-reaction-separation integrated short-contact cyclone reactor

A heterogeneous phase and reactor technology, applied in the direction of chemical methods, chemical instruments and methods, chemical/physical processes, etc. that make liquids react with liquids, can solve the problems of reducing system economy, slow reaction rate, etc., and achieve maintenance costs Low, short reaction time, large processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

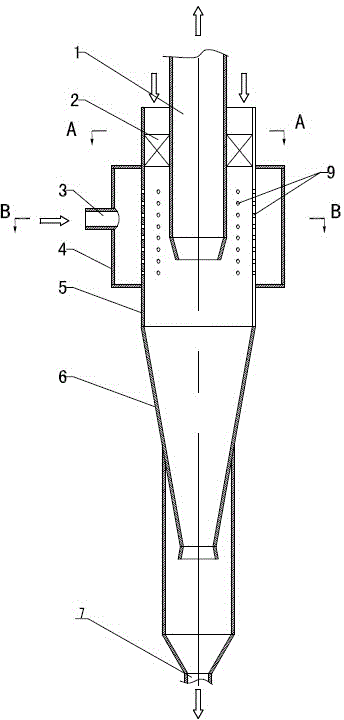

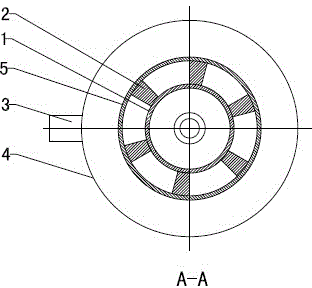

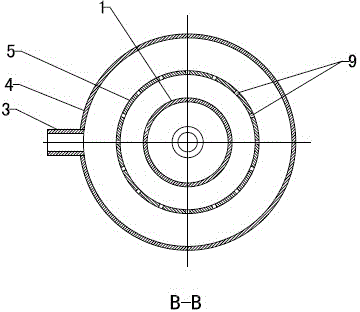

[0029] Refer to attached Figure 1~3 : A short-contact cyclone reactor integrated with liquid-liquid heterogeneous mixing, reaction and separation, comprising an outer cylinder 4 and an inner cylinder 5, the outer cylinder 4 is set on the outer upper part of the inner cylinder 5, the outer cylinder 4 and the inner cylinder 5 An annular cavity is formed between the inner cylinders 5, and the annular cavity is a buffer zone for light-phase liquid raw materials, and a light-phase liquid inlet pipe 3 is provided on one side of the outer cylinder 4, and a connecting inner tube 3 is provided on the wall of the inner cylinder 5. The material circulation structure 9 between the inner cavity of the cylinder body 5 and the annular cavity; the upper part of the inner cylinder body 5 is covered with a light phase overflow outlet pipe 1, and an annular mixing cavity is formed between the light phase overflow outlet pipe 1 and the inner cylinder body 5 , and the upper part of the light phas...

Embodiment 2

[0041] Refer to attached Figure 4 and 5 : The strong rotation structure is the guide inlet pipe 8, one end of the guide inlet pipe 8 is fixedly connected to the tangential direction of the upper outer part of the inner cylinder body 5, and the top of the annular mixing cavity on the upper part of the inner cylinder body 5 is sealed, and the guide inlet pipe 8 is the most important Phase raw material inlet tube.

[0042] The heavy-phase liquid raw material enters the upper part of the inner cylinder 5 through the heavy-phase raw material guide inlet pipe 8, and rotates and flows in the inner cylinder 5; other settings and working processes are the same as those in Embodiment 1.

Embodiment 3

[0044] The material circulation structure is a filter screen embedded in the upper part of the inner cylinder body 5 . Other settings and working process are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com