Automobile steel plate spring assembly with auxiliary spring made of composite material and assembly method thereof

A technology of composite material and automobile steel plate, which is applied in the field of leaf spring assembly and automobile leaf spring assembly, which can solve the problem of failure of leaf spring fatigue life to improve vehicle driving safety, affect automobile fuel economy, and uneven stress distribution, etc. problems, to achieve the effect of improving fuel economy, reducing weight and increasing service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The present invention will be further described below in conjunction with specific embodiments with reference to the accompanying drawings.

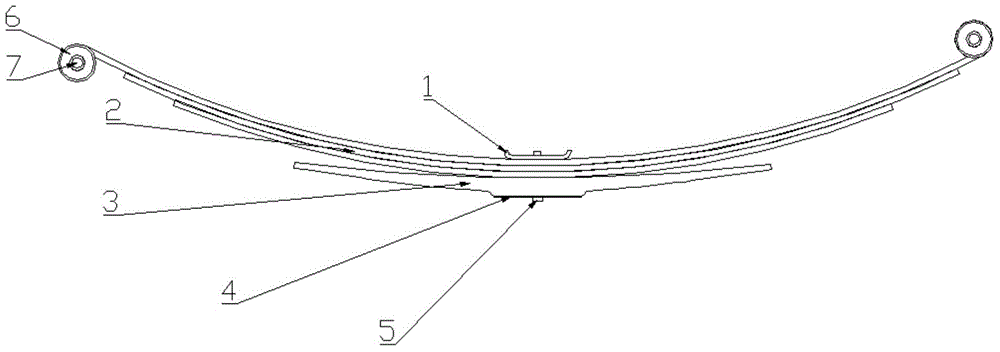

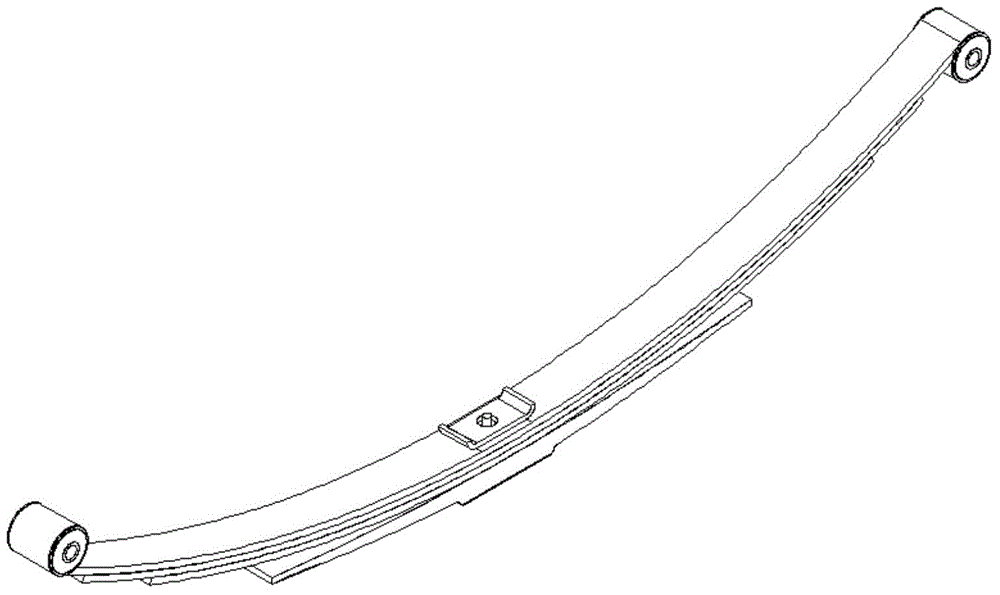

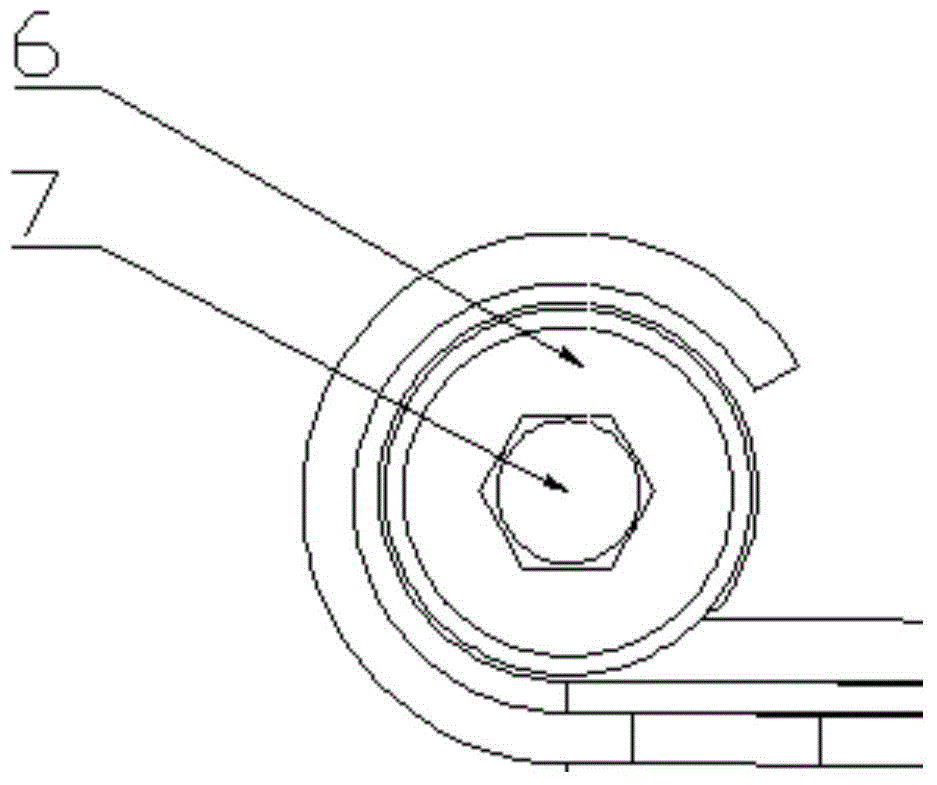

[0056] As shown in Figure 1(a) and Figure 1(b), an automobile leaf spring assembly with a secondary spring made of composite materials includes a U-bolt metal splint, a main spring, a secondary spring and a lower gasket, and the lower gasket , auxiliary spring, main spring, and U-bolt metal splints are stacked in sequence from bottom to top, and then fixed and connected by the central bolt to limit the position, and are clamped and fixed by U-shaped bolts. After fixing, the automobile leaf spring assembly passes through the central bolt 5 Installed on the vehicle axle, a pair of U-shaped bolts are arranged on the automobile leaf spring assembly by means of internal eight-shaped cable-staying, and the rubber bushing 6 and the matching bolt 7 are assembled to the front and rear leaf spring lugs at both ends of the leaf spring main sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com