Lubricating agent composition for low heat rejection diesel engine

A lubricant composition, a technology for diesel engines, applied in the directions of lubricating compositions, petroleum industry, etc., can solve problems such as the inability of lubricants to meet high-temperature lubrication, and achieve the effects of reducing emissions, good shear resistance, and low volatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

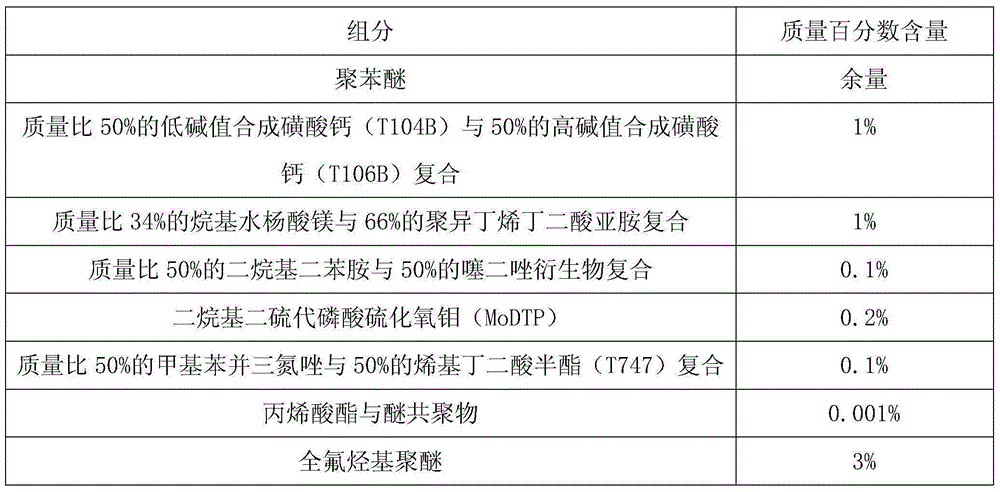

Embodiment 1

[0017] Embodiment 1: each component is reconciled and forms by following mass percentage:

[0018]

[0019] The sum of the mass percentages of the above components is 100%.

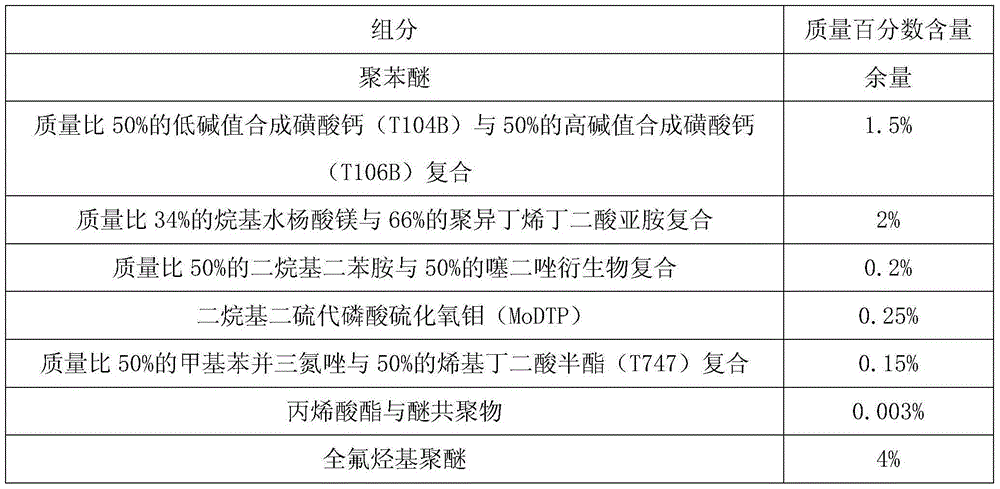

Embodiment 2

[0021] The components are blended according to the following mass percentages:

[0022]

[0023] The sum of the mass percentages of the above components is 100%.

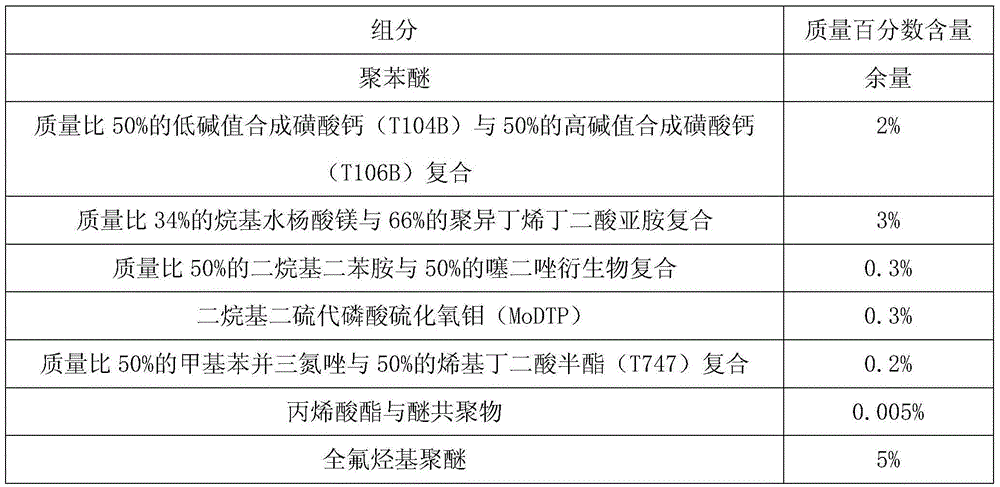

Embodiment 3

[0025] The components are blended according to the following mass percentages:

[0026]

[0027] The sum of the mass percentages of the above components is 100%.

[0028] The main physical and chemical index of embodiment 3 products:

[0029] project

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com