Vacuum hard coating water needle plate and manufacturing method thereof

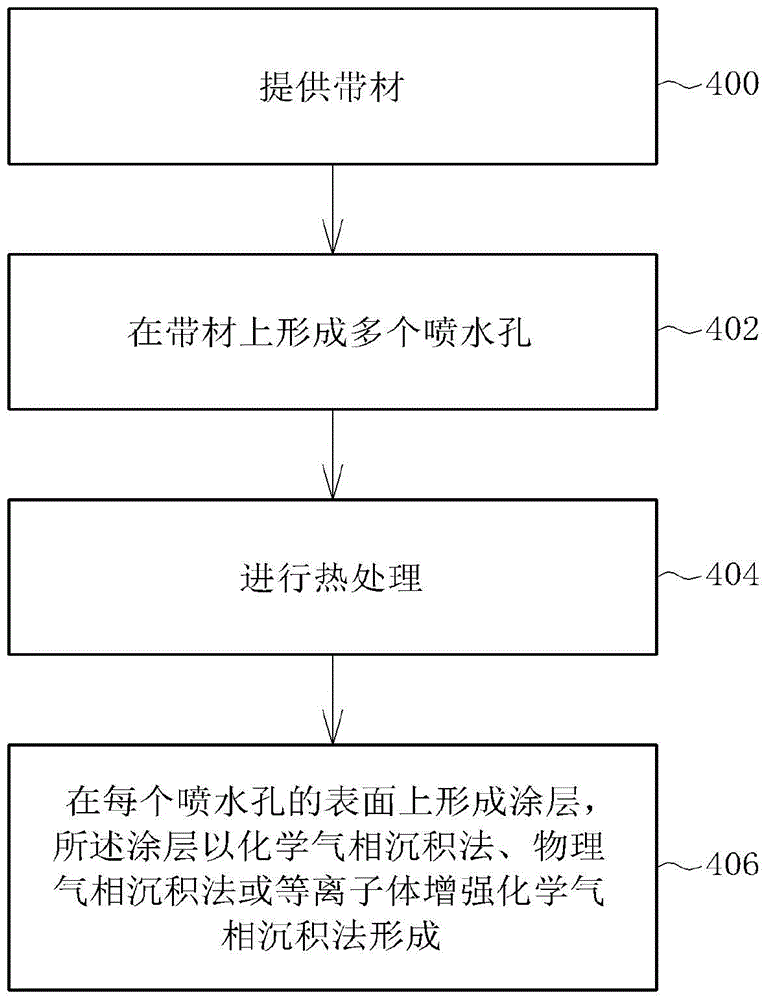

A manufacturing method and technology of water jet plate, which are applied in coating, vacuum evaporation coating, metal material coating process, etc., can solve the problems of unstable water pressure, waste of resources, short service life, etc., and reduce the possibility of wear and tear , The effect of delaying clogging and improving wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

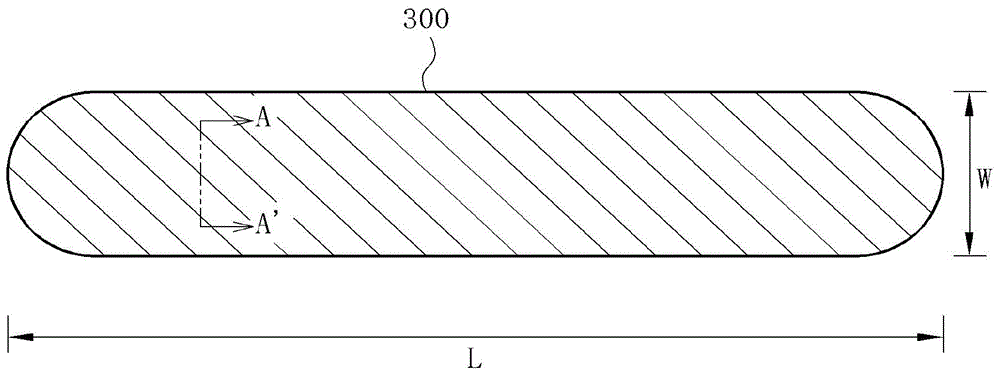

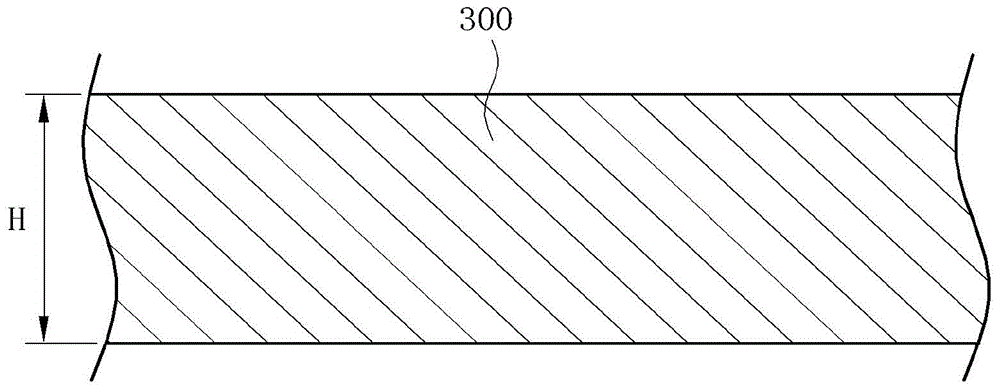

[0028] The strip is made of SUS301 material, the hardness of the base material is HV300, the length L is 4.8 meters, the width W is 25 mm, and the thickness H is 1 mm. Drilling and milling are used to form a row of water spray holes. The specific size of the water spray holes is that the diameter Φa of the central hole 3 is 0.12 mm, Φb is 0.35 mm, the hole distance b is 0.6 mm, and the number of holes is 7000. Finally, PVD vacuum coating technology is used to coat a layer of TiN (titanium nitride) vacuum hard coating, in the way of hollow cathode discharge coating, with titanium (Ti) block, at 380 ° C, -80V bias, 160A bias current , 0.8 Pa air pressure, and 500 SCCM N2 flow conditions for 1 hour to obtain a 3 micron TiN coating with a surface hardness of HV2300.

[0029]Because most of the jet strips in the prior art are manufactured by traditional processes, their tolerance cannot be improved. The present invention combines the advanced vacuum vapor deposition process, and in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com