Plastic connecting method of aluminum copper structure

A connection method and plastic technology, applied in welding equipment, non-electric welding equipment, metal processing equipment, etc., can solve the problems of easy oxidation of aluminum and copper, increase the difficulty of implementing the solid-phase bonding process, reduce the connection performance, etc., and achieve low equipment cost. , convenient for mass production, good reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

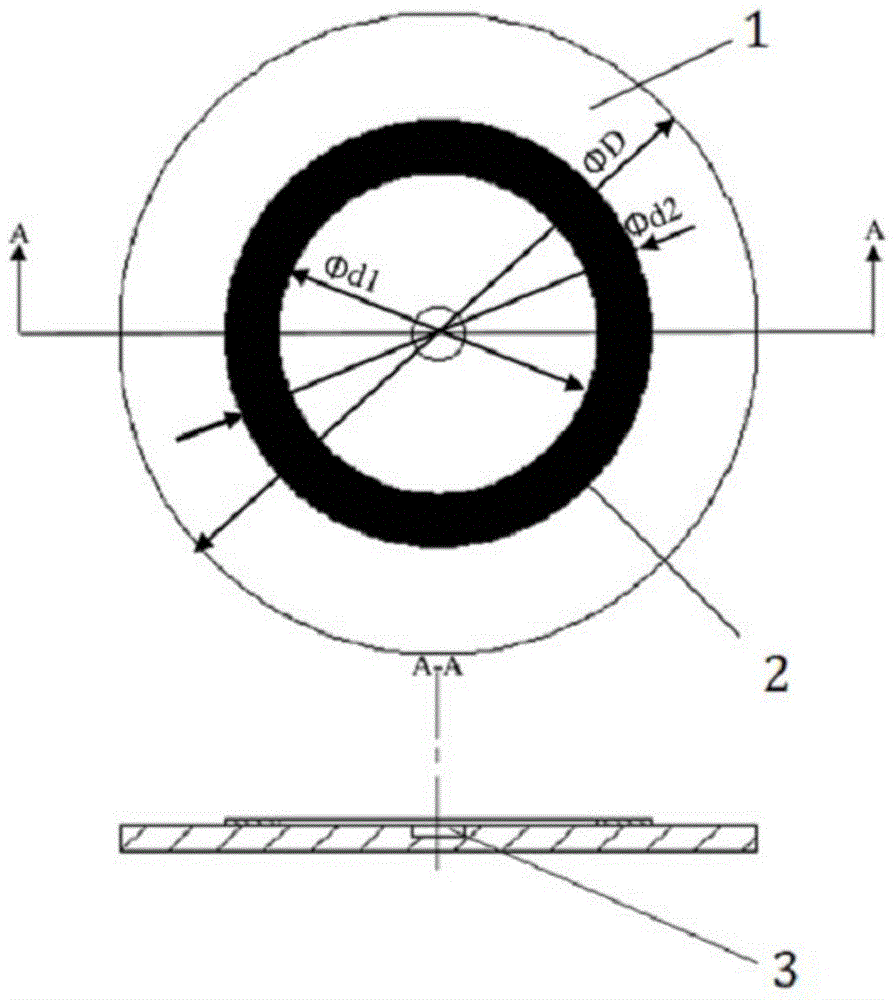

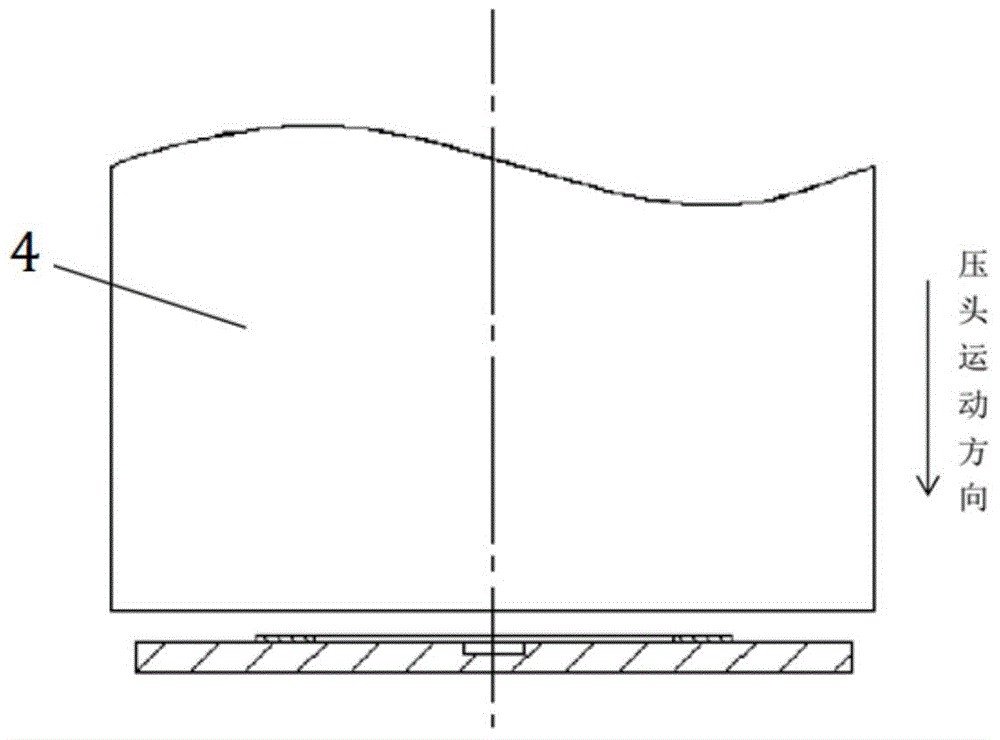

[0020] Such as figure 1 and figure 2 As shown, in this embodiment, the materials of the copper ring and the aluminum part are pure copper and pure aluminum respectively, and a Φ4×1mm counterbore is provided in the center of the aluminum part to facilitate subsequent assembly. The diameter of the aluminum part is D=60mm, and the thickness is 2.5mm. Surface area to be connected S = 1320mm 2 . The steps of this embodiment are as follows:

[0021] 1) Prepare the copper ring and the aluminum parts. The ring-shaped sheet obtained by processing the annealed copper sheet through the punching and blanking process, the outer diameter and inner diameter of the copper ring d1 = 30mm, and the thickness of the copper ring h = 0.6mm , the expected thinning rate is 58.3%, and d2 is calculated as 40mm. After the aluminum material is processed and the aluminum parts are obtained, aging treatment is carried out to improve its strength to meet the actual use requirements, and at the same tim...

Embodiment 2

[0028] Such as figure 1 and figure 2 As shown, in this embodiment, the materials of the copper ring and the aluminum part are pure copper and pure aluminum respectively, and a Φ4×1mm counterbore is provided in the center of the aluminum part to facilitate subsequent assembly. The diameter of the aluminum part is D=70mm, and the thickness is 2.5mm. Surface area to be connected S = 1507mm 2 . The steps of this embodiment are as follows:

[0029] 1) Prepare the copper ring and the aluminum piece, and process the ring-shaped sheet obtained by punching and blanking the copper sheet in the annealed state. The outer diameter and inner diameter of the copper ring are d1=35mm, and the thickness of the copper ring is h=0.6mm , the expected thinning rate is 58.3%, and d2 is calculated as 45mm. After the aluminum material is processed and the aluminum parts are obtained, aging treatment is carried out to improve its strength to meet the actual use requirements, and at the same time, ...

Embodiment 3

[0036] Such as figure 1 and figure 2 As shown, in this embodiment, the materials of the copper ring and the aluminum part are pure copper and pure aluminum respectively, and a Φ4×1mm counterbore is provided in the center of the aluminum part to facilitate subsequent assembly. The diameter of the aluminum part is D=60mm, and the thickness is 2.5mm. Surface area to be connected S = 1357mm 2 . The steps of this embodiment are as follows:

[0037] 1) Prepare the copper ring and the aluminum parts. The ring-shaped sheet obtained by processing the annealed copper sheet through the punching and blanking process, the outer diameter and inner diameter of the copper ring d1 = 30mm, and the thickness of the copper ring h = 0.6mm , It is estimated that the thinning rate is 50%, and d2 is calculated as 42mm. After the aluminum material is processed and the aluminum parts are obtained, aging treatment is carried out to improve its strength to meet the actual use requirements, and at th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com