Dehydration anti-corrosion device for constant top equipment

An anti-corrosion device and equipment technology, applied in the direction of preventing corrosion during distillation, can solve the problems of corrosion under scale, small and difficult injection of corrosion inhibitors and ammonia water, etc., and achieve the effect of eliminating corrosion, simple structure and corrosion prevention.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

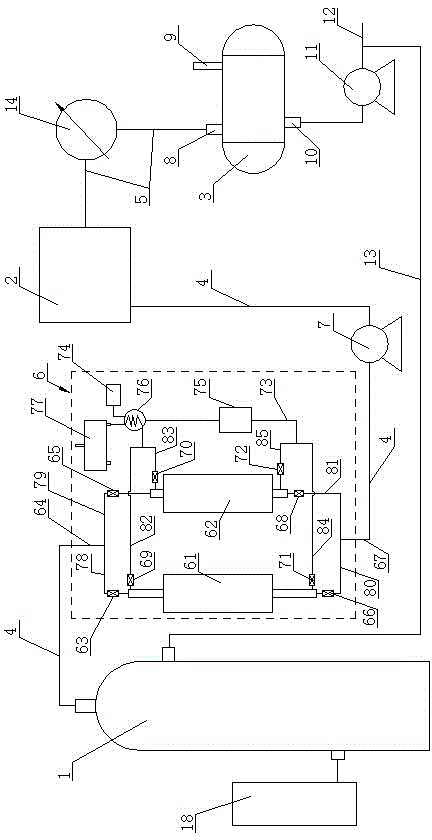

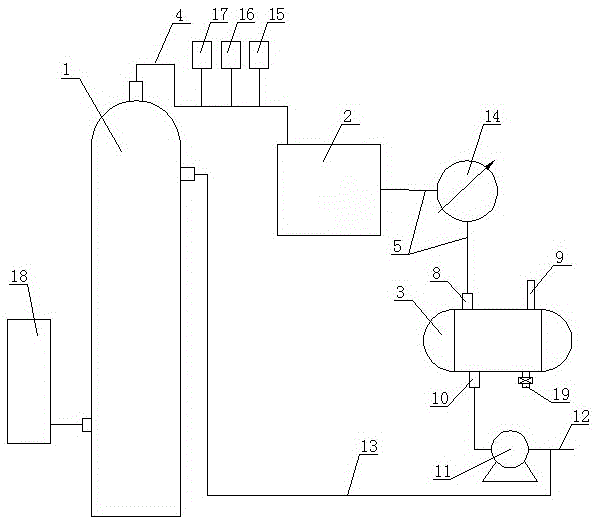

[0015] The invention is in figure 2 The improvement made on the basis of the anticorrosion device of the existing constant top equipment shown, that is, on the basis of the prior art, the water injection device 15, the ammonia water injection device 16 and the water injection device 16 connected to the distillation pipe 4 are connected. Inject the corrosion inhibitor device 17 and remove it, and then connect the drying water removal system and the delivery pump on the distillation pipe 4 in series. The specific structure is as follows.

[0016] The dehydration anti-corrosion device of constant top equipment provided by the present invention is as figure 1 As shown, it includes an atmospheric column (atmospheric distillation column) 1, an air cooler 2 and a reflux tank 3. The reflux tank 3 includes a tank body, the top of which is provided with a liquid inlet 8 and an exhaust pipe 9 for exhaust, and the bottom of the tank is provided with a liquid outlet 10 . The inlet of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com