A method for metal plasma immersion ion implantation and deposition of insulating material

A metal plasma and immersion ion implantation technology, applied in ion implantation plating, metal material coating process, coating and other directions, can solve the problems of equipment damage, inability to achieve neutralization of accumulated charges on the surface of insulating materials, and ignition, etc. Achieve the effect of reducing the degree of charge accumulation, improving the implantation effect, and increasing the energy of ion implantation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

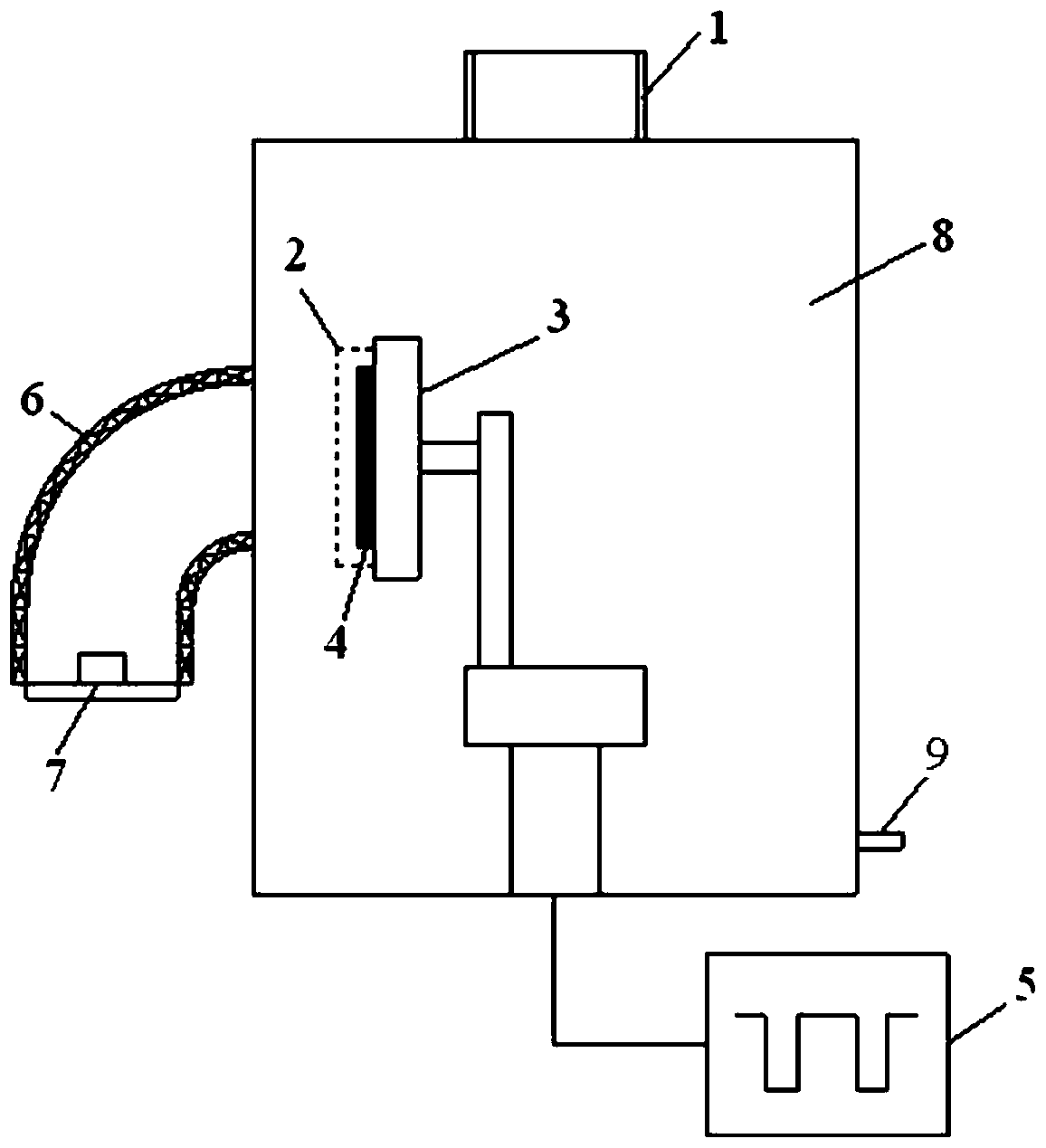

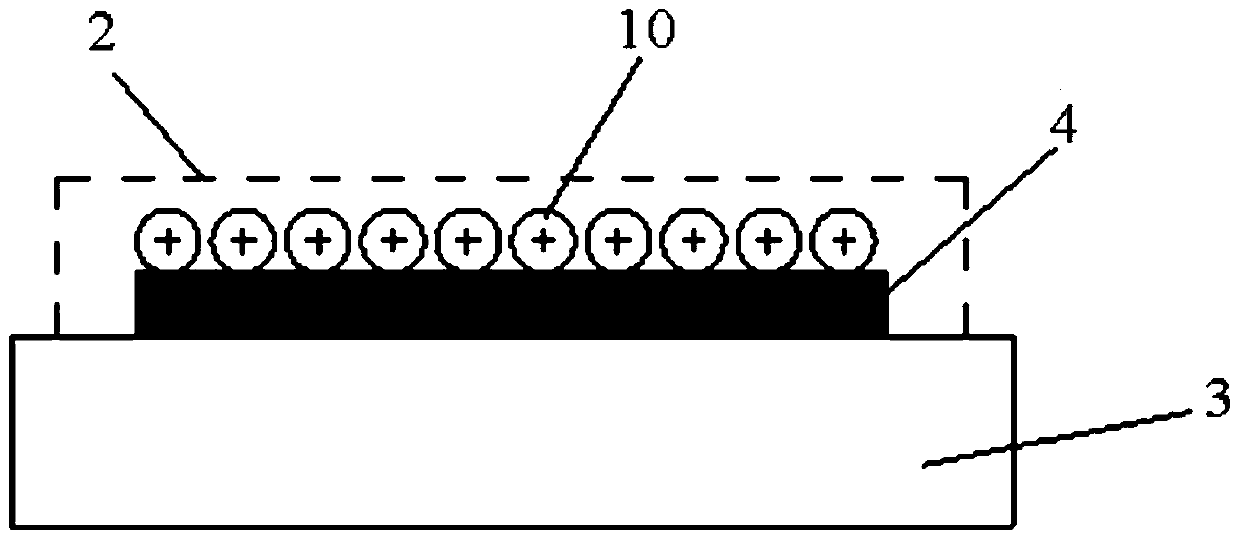

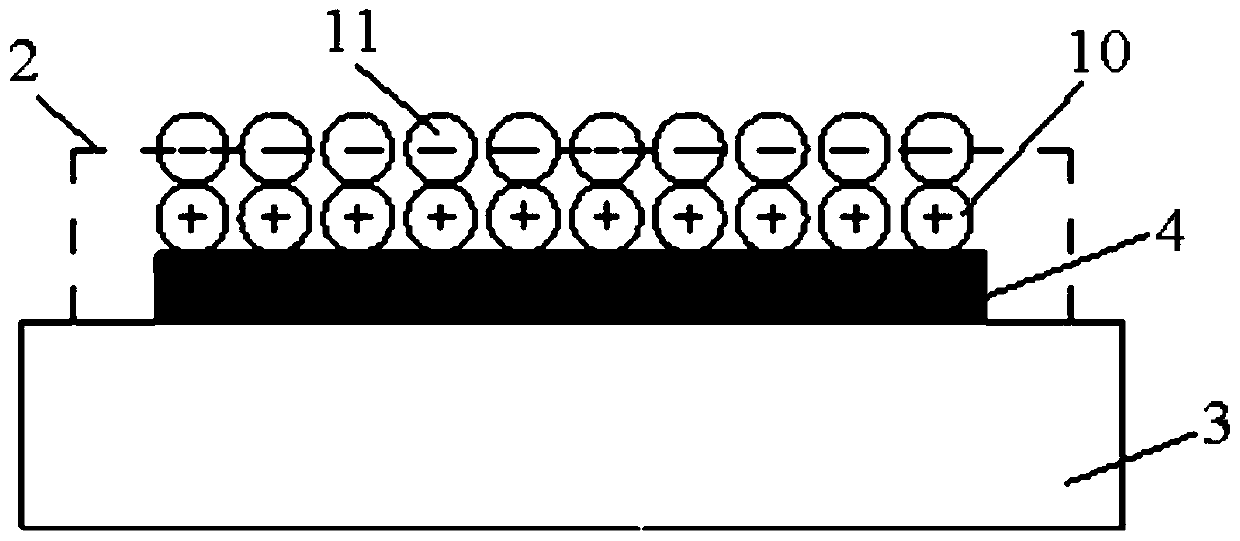

[0025] Specific embodiment 1: This embodiment is an insulating material metal plasma immersion ion implantation and deposition device including a gas plasma source 1, a metal grid 2, a high-voltage target 3, an insulating workpiece to be processed 4, and a negative high-voltage pulse source 5. , Magnetic conduit 6, metal cathode arc plasma source 7, vacuum chamber 8 and air inlet 9;

[0026] The vacuum chamber 8 is provided with a metal grid 2, a high-voltage target platform 3, and an insulated workpiece 4 to be processed; the insulated workpiece 4 to be processed is installed above the high-voltage target platform 3, and the metal grid 2 is covered above the high-voltage target platform 3. And it is connected with the high-voltage target stage 3;

[0027] The gas plasma source 1 and the gas inlet 9 are respectively communicated with the vacuum chamber 8;

[0028] The negative high voltage pulse source 5 is connected to the high voltage target platform 3;

[0029] The magnetic condui...

specific Embodiment approach 2

[0036] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the insulating workpiece 4 to be processed is alumina ceramic, polytetrafluoroethylene, nylon or organic glass. Others are the same as the first embodiment.

specific Embodiment approach 3

[0037] Specific embodiment 3: The difference between this embodiment and specific embodiments 1 or 2 is that the material of the metal grid 2 is stainless steel, titanium metal or copper metal. Others are the same as the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com