Coal mass strength distribution characteristic continuous detecting method and device

A technology of strength distribution and detection method, applied in drilling equipment and methods, measurement, earthwork drilling and mining, etc., can solve problems such as difficult application, inaccurate reflection of coal body strength, great influence of drilling power, etc., and achieve the best results Accurate, scientific effect of test principle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

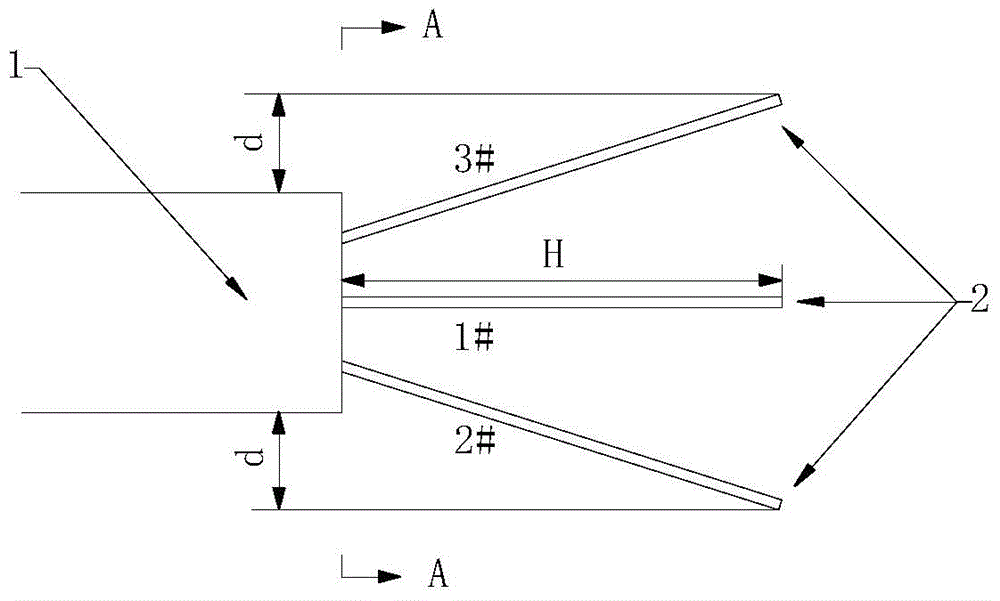

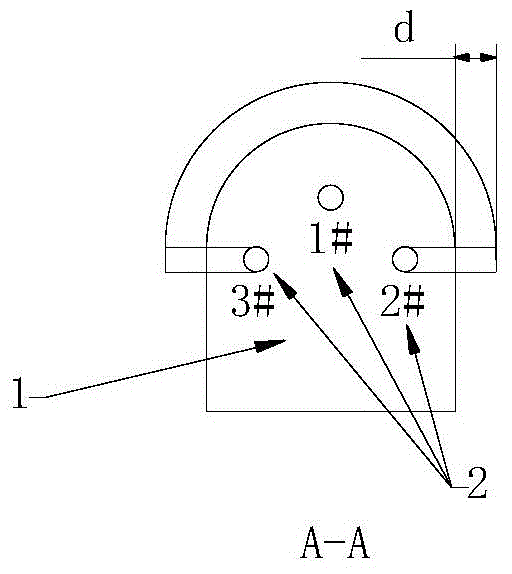

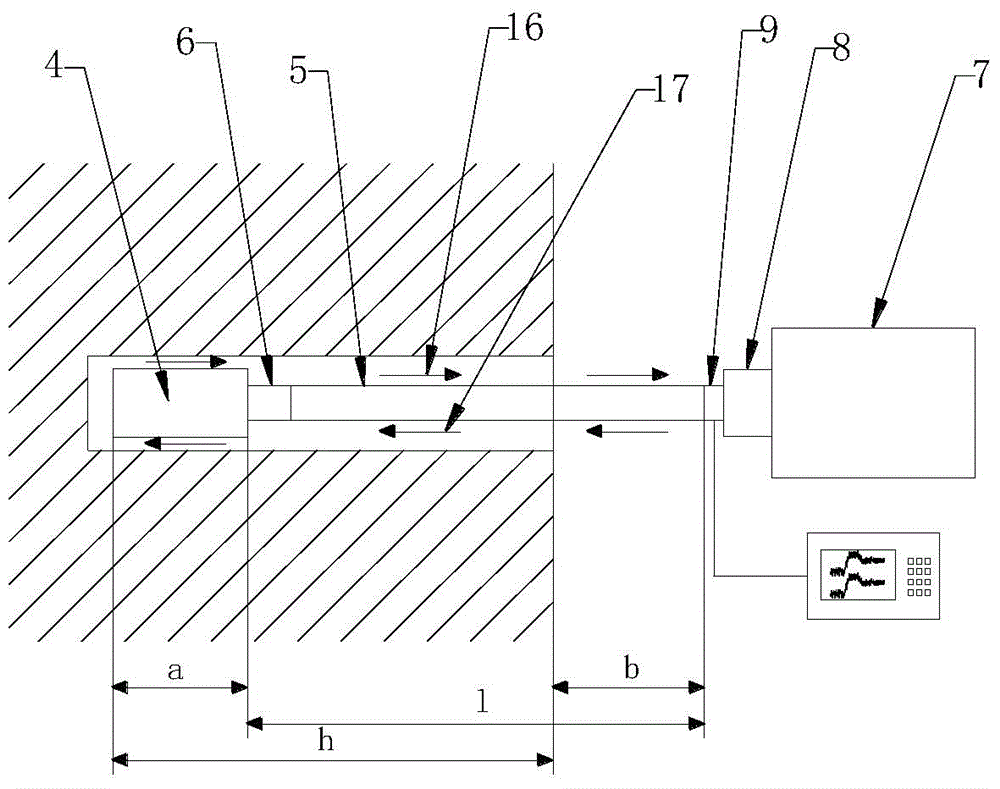

[0027] Embodiment 1. For a near-horizontal outburst coal seam of a certain outburst mine, as shown in Figure 1 (a), when the outburst prediction of the driving face 1 is carried out, the advance prediction drilling 2 is constructed in front of the coal roadway driving face 1, according to The outburst prevention regulation should construct at least 3 drill holes in front of the coal body in the near-horizontal and gently inclined coal seam working face, with a diameter of 42mm and a depth H of 8-10m, to test the analysis index of cuttings gas and the amount of cuttings ; Borehole 2 is arranged in the soft layer of coal body 3 as much as possible. One hole is shown in Figure 1(a). Hole 1# is located in the middle of the excavation roadway section and parallel to the direction of excavation. The other two holes are shown in Figure 1 (a) 2#, 3# holes, the final hole points of 2#, 3# holes should be located 2~4m outside the contour line on both sides of the roadway section, recorde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com