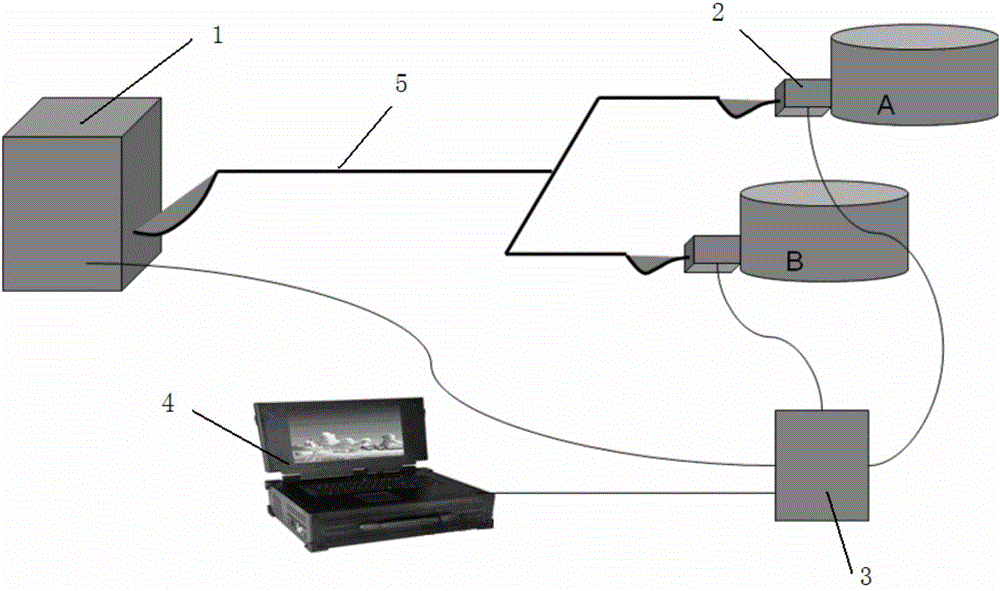

Method solving air preheater dust clogging problem and intelligent online flushing system

An air preheater and flushing system technology, which is used in flushing, cleaning heat transfer devices, lighting and heating equipment, etc., can solve the problems of the flushing range of the flushing device being limited by height, the shutdown of the flushing process, and affecting the production efficiency. The effect of reduced energy consumption, increased flushing efficiency, and reduced fume loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

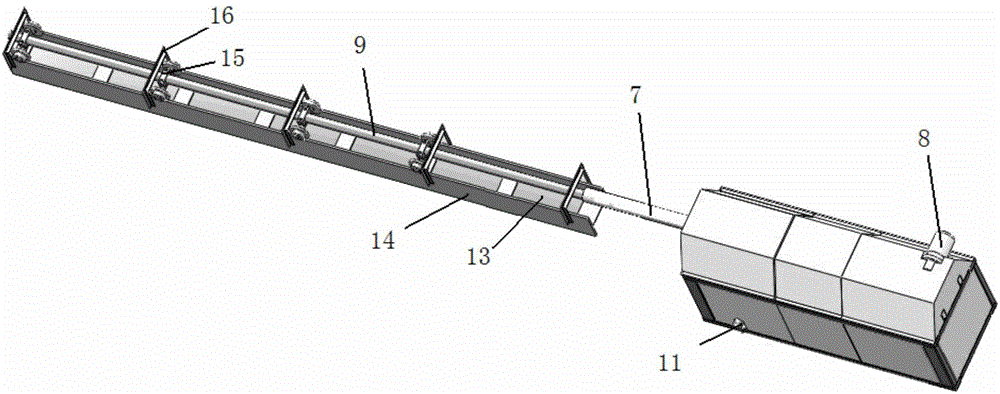

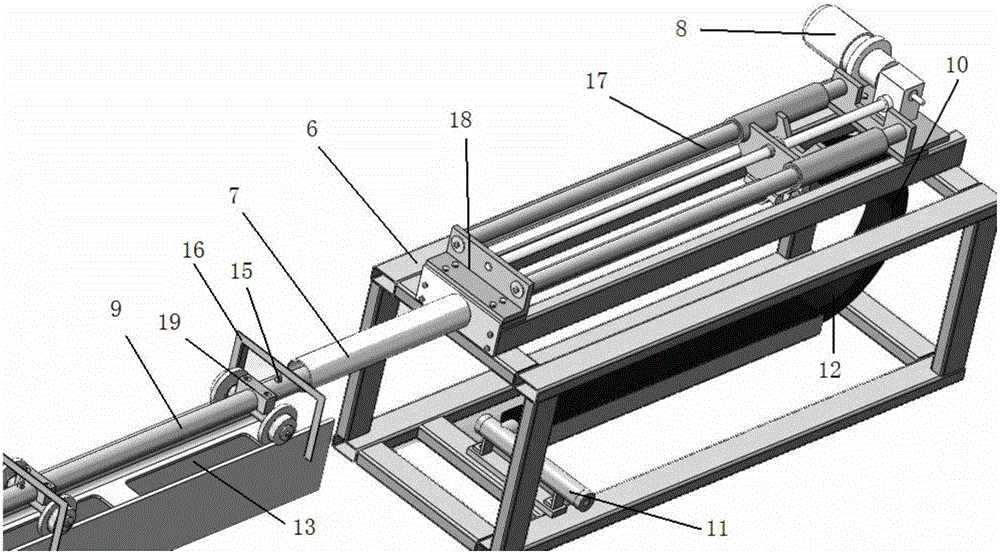

Embodiment 1

[0059] When the operating pressure difference on the flue gas side of the air preheater reaches 1.2-1.3 times the design pressure, the flushing device is manually activated through the upper computer system and the electric control cabinet, and the driving motor of the flushing device drives the flushing gun barrel to extend to the air preheater The distance between the nozzle of the flushing nozzle and the surface to be flushed is 200mm, aiming at the air preheater partition for flushing, the pressure of the water flow at the flushing nozzle is 70Mpa, and the water volume is 60L / min.

[0060] The 1# furnace and 2# furnace of a power plant are 350MW subcritical coal-fired boilers, and the air preheater is a rotary type. The effect of flushing is shown in the table below:

[0061]

[0062] From the data in the above table, before flushing, the pressure difference on the flue gas side of the A side of the 1# furnace and the B side of the 2# furnace is relatively high, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com