Brightness enhancement film having blue light resistance effect and manufacturing method thereof

A manufacturing method and anti-blue light technology, applied in the directions of optics, optical components, instruments, etc., can solve the problems of eye damage, no anti-blue light function, etc., and achieve the effect of simple and easy manufacturing method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

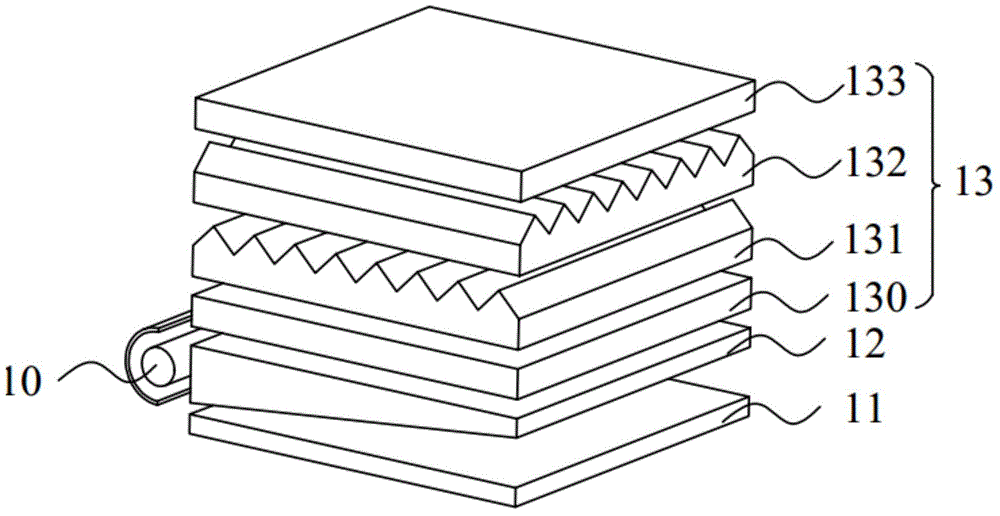

[0048] like figure 1 As shown, the backlight module includes a backlight 10, a reflective film 11, a light guide plate 12, and an optical film group 13. There is an optical film group 13; wherein the optical film group 13 includes a lower diffusion film 130, a lower brightness enhancement film 131, an upper brightness enhancement film 132 and an upper diffusion film 133 arranged in sequence from bottom to top. The length directions of the prism monomers of the lower brightness enhancement film 131 and the upper brightness enhancement film 132 are perpendicular to each other.

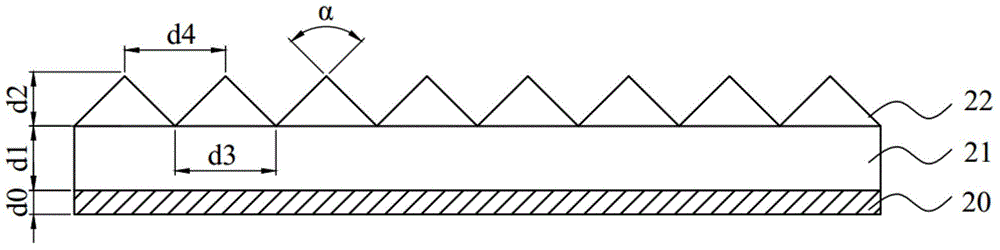

[0049] The brightness enhancement film with anti-blue light effect provided by this embodiment includes: a substrate 21 , a prism structure layer 22 and an anti-blue light layer 20 . The substrate 21 includes a first optical surface and a second optical surface; the prism structure layer 22 is arranged on the first optical surface, and the anti-blue light layer 20 is arranged on the second optical surfa...

Embodiment approach 2

[0068] like Figure 7 As shown, the brightness enhancement film (the lower brightness enhancement film 131 and the upper brightness enhancement film 132 ) provided in this embodiment includes: a substrate 21 , a prism structure layer 22 and an anti-blue light layer 20 . The substrate 21 comprises a first optical surface and a second optical surface; the prism structure layer 22 and the anti-blue light layer 20 are arranged on the second optical surface; A prism structure layer 22 is provided thereon. The prism structure layer 22 is composed of a plurality of prism monomers, and all the prism monomers are arranged horizontally with each other along the length direction thereof.

[0069] The thickness d0 of the substrate 21 is 38 μm, the thickness d2 of the prism structure layer 22 is 13 μm, and the thickness d1 of the anti-blue light layer 20 is 4 μm. The cross-section of the prism monomer in the prism structure layer 22 is an isosceles triangle, the apex angle α of the isosc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com