Multi-junction GaAs thin-film solar cell based on forward mismatched epitaxial growth

A solar cell and battery technology, applied in the field of solar cells, can solve the problems of expensive preparation of GaAs thin-film solar cells, etc., and achieve the effects of improving photoelectric conversion efficiency, improving application prospects, and high connection mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

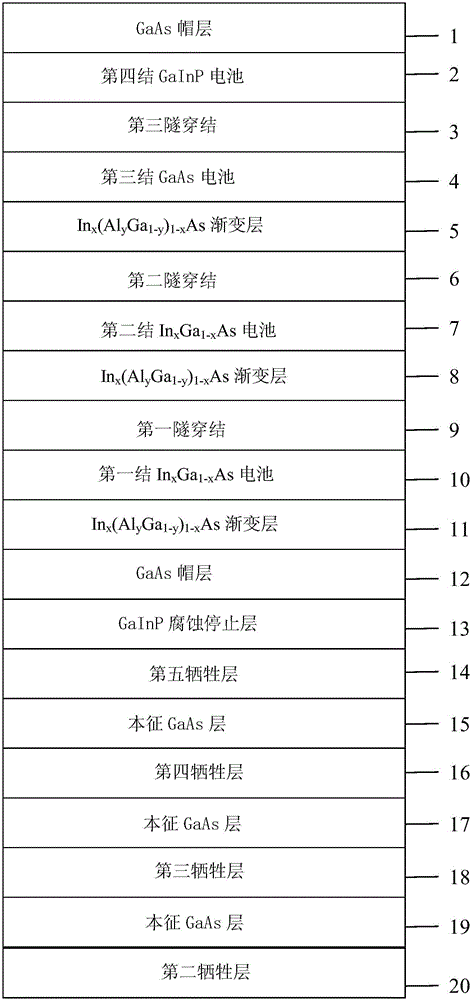

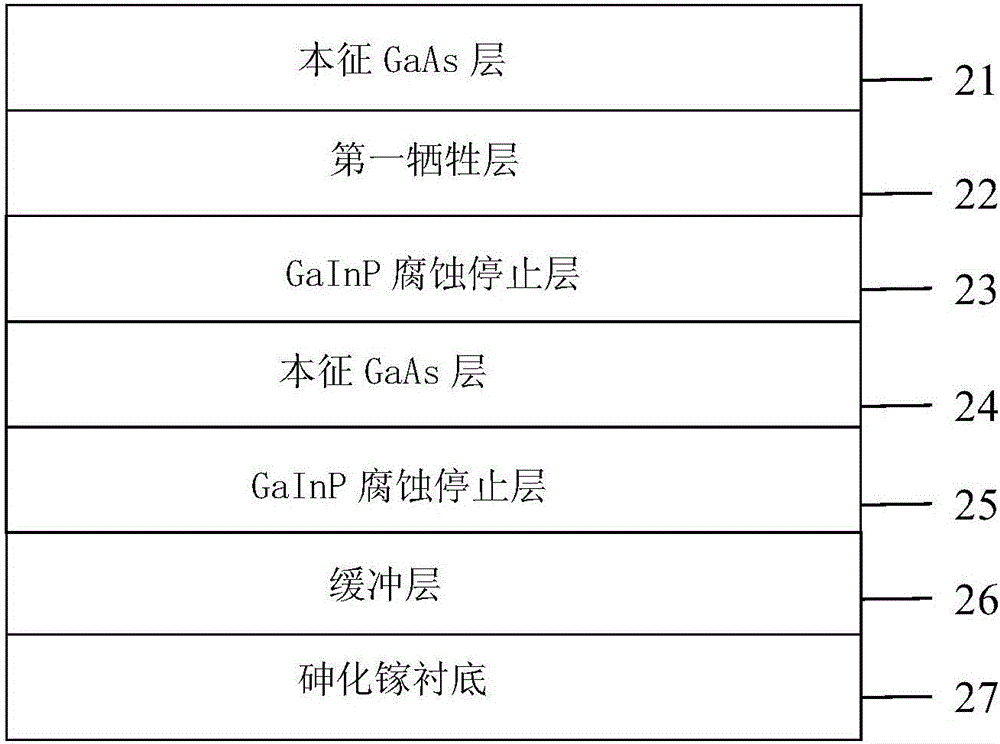

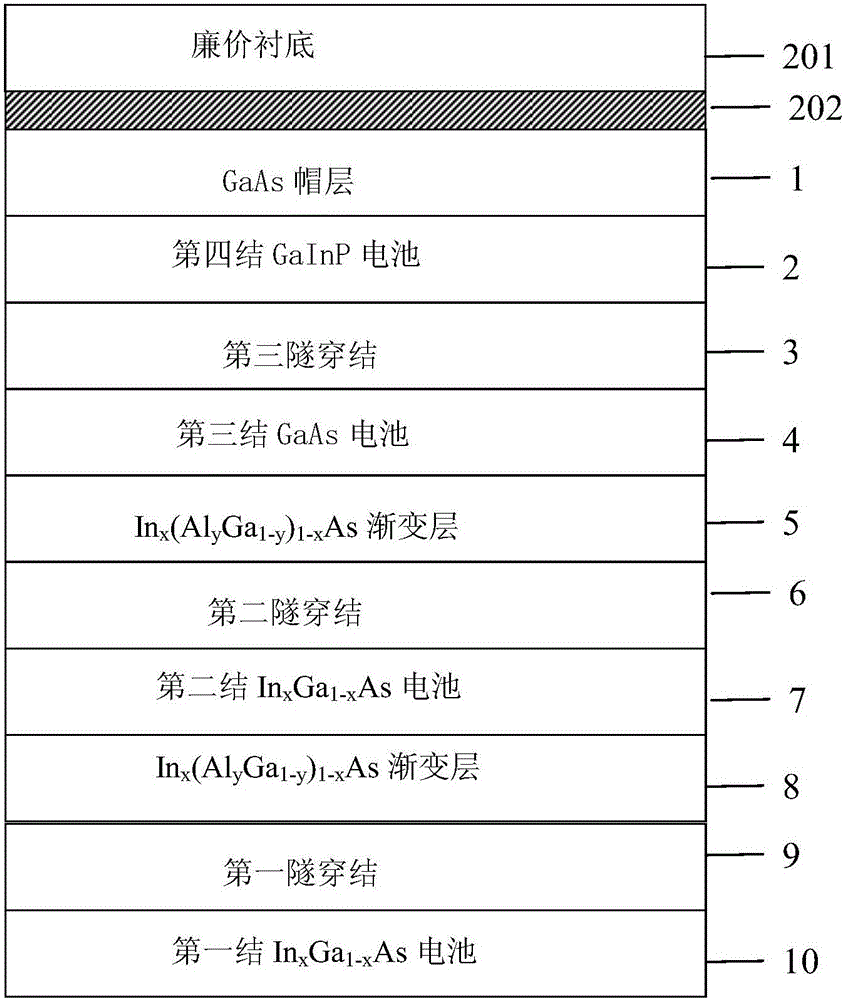

[0040] This embodiment provides a GaAs four-junction thin-film solar cell based on epitaxial forward mismatch growth. Firstly, a structure combining the cell body and the active layer of the cell is prepared, including a gallium arsenide substrate, a buffer layer, a GaInP corrosion stop layer, and this Intrinsic GaAs layer, GaInP etch stop layer, first sacrificial layer, intrinsic GaAs layer, second sacrificial layer, intrinsic GaAs layer, third sacrificial layer, intrinsic GaAs layer, fourth sacrificial layer, intrinsic GaAs layer, second sacrificial layer Five sacrificial layers, GaInP etch stop layer, GaAs cap layer, In x (Al y Ga 1-y ) 1-x As gradient layer, first junction In x Ga 1-x As cell, first tunnel junction, In x (Al y Ga 1-y ) 1-x As gradient layer, second junction In x Ga 1-x As cell, second tunnel junction, In x (Al y Ga 1-y ) 1-x As graded layer, third junction GaAs cell, third tunnel junction, fourth junction GaInP cell, GaAs capping layer.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com