Methanol hydrogen production energy-storage fuel cell base station standby power supply system and control method thereof

A fuel cell and backup power technology, applied in the direction of fuel cells, fuel cell additives, emergency power arrangements, etc., can solve the problems of large storage volume and poor safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

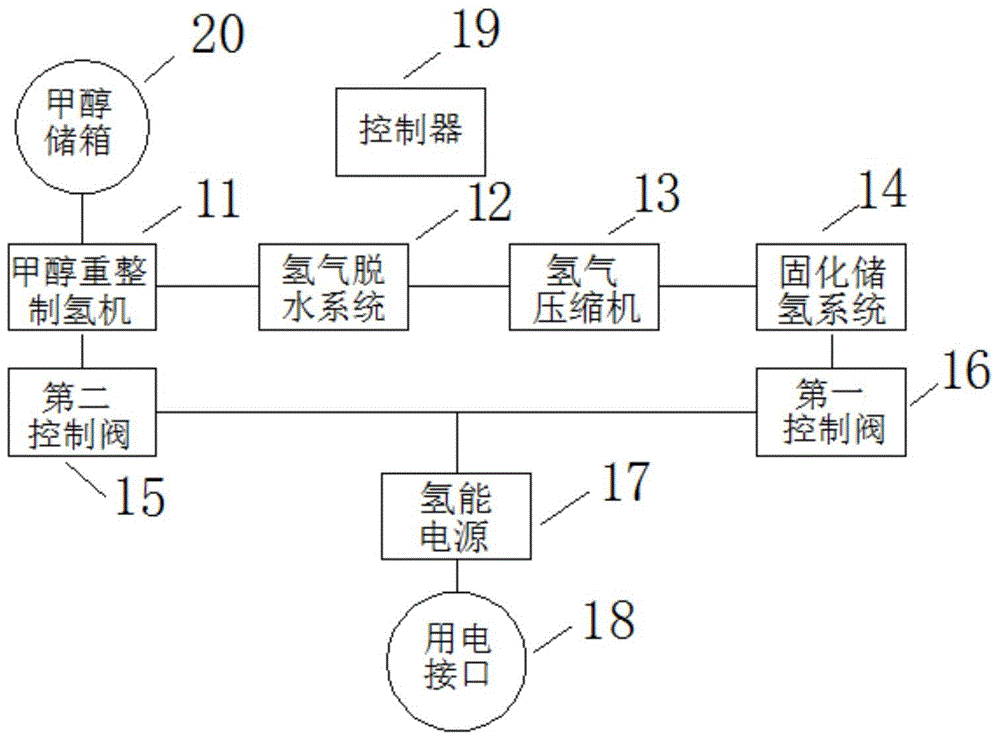

[0062] Please refer to figure 1 , figure 1 It is a block diagram of the first specific embodiment of a fuel cell base station backup power system for methanol-to-hydrogen energy storage in the present invention.

[0063] Such as figure 1 As shown, the fuel cell base station backup power system for methanol hydrogen production and energy storage includes a methanol reforming hydrogen generator 11, a hydrogen energy power supply 17 (HT-PEMFC hydrogen energy power supply), a controller 19, a solidified hydrogen storage system 14, a first control Valve 15, second control valve 16, hydrogen compressor 13, hydrogen dehydration system 12. The hydrogen energy power supply 17 is provided with an electrical interface 18 .

[0064] The methanol reforming hydrogen generator 11, the hydrogen energy power supply 17 and the solidified hydrogen hydrogen storage system 14 are interconnected; a first control valve 15 is provided between the methanol reforming hydrogen generator 11 and the hy...

Embodiment 2

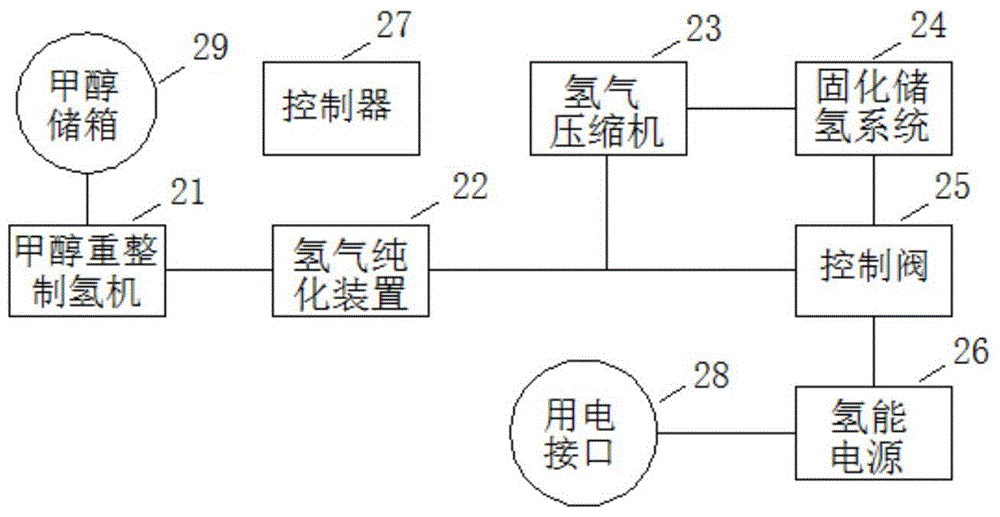

[0070] Please refer to figure 2 , figure 2 It is a block diagram of the second specific embodiment of the fuel cell base station backup power system for methanol-to-hydrogen energy storage of the present invention.

[0071] In this embodiment, the fuel cell base station backup power system for methanol hydrogen production and energy storage, the system includes a methanol reforming hydrogen production machine 21, a hydrogen energy power supply 26, a controller 27, a solidified hydrogen storage system 24, a hydrogen purification device 22, Control valve 25, hydrogen compressor 23. The hydrogen energy power supply 26 is provided with an electrical interface 28 .

[0072] The methanol reforming hydrogen generator 21, the hydrogen energy power supply 26 and the solidified hydrogen storage system 24 are connected to each other; the controller 27 detects and controls the information and actions of each unit.

[0073] The methanol reforming hydrogen generator 21 is connected to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com