A starch jelly and a preparation method thereof

A starch and jelly technology, applied in the field of food processing, can solve problems such as single taste, and achieve the effect of improving single taste, delicate texture and high nutritional value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

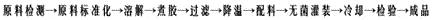

Method used

Image

Examples

Embodiment 1

[0019] First, heat and mix edible gum, some sweeteners, and water in proportion, raise the temperature to 75-95°C, and keep it for 5-15 minutes. Pass it through a 100-mesh stainless steel screen to obtain the mixed solution 1. Fully swell the starch with water to obtain a starch solvent, then add edible oil and the remaining sweetener, heat and mix, raise the temperature to 75-95°C, and keep it for 5-15 minutes, pass it through a 100-mesh stainless steel screen to obtain a mixed solution 2. Heat and mix the mixed solution 1 and the mixed solution 2 to obtain the mixed material solution. When the mixed material solution drops to about 70°C, add the remaining raw materials and mix evenly. After passing the inspection, sterilize and cool to obtain the starch jelly.

Embodiment 2

[0021] First, heat and mix edible gum, some sweeteners and water in proportion, raise the temperature to 75-95°C, and keep it in the state for 5-15 minutes, pass it through a 100-mesh stainless steel screen to obtain the mixed solution 1, and mix it with The starch is fully swollen with water, and the fresh milk that has been cleaned and sterilized is added to obtain a starch solvent, then edible oil and remaining sweetener are added, heated and mixed, the temperature is raised to 75-95°C, and the state is maintained for 5-15 minutes. Mesh stainless steel sieve to obtain mixed solution 2, heat mixed solution 1 and mixed solution 2 to obtain mixed material liquid, when the mixed material liquid drops to about 70°C, add the remaining raw materials and mix evenly, after passing the inspection, sterilize After cooling, the starch jelly is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com