Au/BW11/Al2O3 catalyst and its preparation method and use

A BW11, catalyst technology, applied in the field of Au/BW11/Al2O3 catalyst and its preparation and application, to achieve the effect of mild conditions, good conversion rate and selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

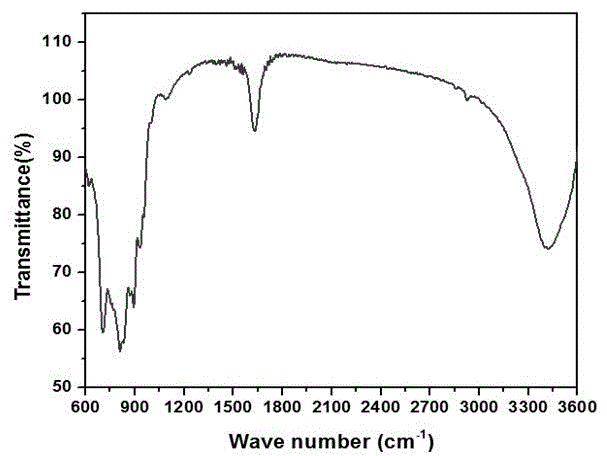

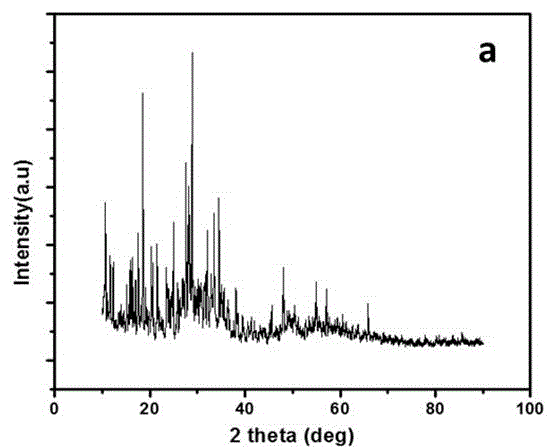

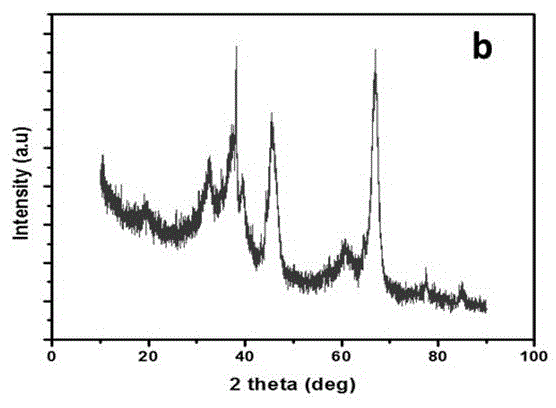

Image

Examples

Embodiment 1

[0038] Catalyst activity evaluation. After calcination of 0.25 g catalyst at 500 °C, it was placed in a PTFE-lined autoclave (volume = 20 mL), 5 g of cyclooctene, molecular oxygen as oxidizing agent and TBHP initiator at 80 °C under a pressure of 0.4 MPa C was reacted for 24 hours. The conversion rate of cyclooctene oxidation was 42.92%, and the selectivity of epoxy cyclooctane was 90.02%.

Embodiment 2

[0040]Catalyst activity evaluation. 0.15 g of catalyst calcined at 500 °C was used for the reaction after 3 cycles. 5 g of cyclooctene, molecular oxygen as an oxidizing agent, and TBHP initiator were reacted at 80°C for 24 hours under a pressure of 0.4 MPa. The conversion rate of cyclooctene oxidation was 36.59%, and the selectivity of epoxy cyclooctane was 85.29%.

Embodiment 3

[0042] Catalyst activity evaluation. 0.15 g of catalyst calcined at 500°C was used for the reaction. 5 g of cyclooctene was dissolved in a 1:1 solution of 2-dichloroethane and acetonitrile, molecular oxygen as an oxidizing agent and a TBHP initiator were reacted at 80°C for 24 hours under a pressure of 0.4 MPa. The obtained cyclooctene oxidation conversion rate is 46.64%, and the selectivity of epoxy cyclooctane is 97.31%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com