G-C3N4/{001}TiO2 composite visible-light-driven photocatalyst and preparation method and application thereof

A g-c3n4, catalyst technology, applied in physical/chemical process catalysts, chemical instruments and methods, separation methods, etc., can solve the problems of increased cost and energy consumption, unfavorable photocatalytic reaction, unfavorable interfacial charge transfer efficiency and catalytic activity. It can greatly improve the problems such as energy saving, low cost and easy availability of raw materials, and good photocatalytic activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] {001}TiO 2 Preparation of powder: 4.5 mL of 40% HF solution was added to 20 mL of tetrabutyl titanate (TBOT), stirred for 30 min at 25 °C to mix well, and then hydrothermally reacted at 180 °C for 20 h, cooled to room temperature after the reaction, washed the solid precipitate several times with ethanol and deionized water, then dried the obtained solid in an oven at 100°C for 4 h, and finally ground it into a fine powder to obtain {001 }TiO 2 powder.

Embodiment 2

[0029] g-C 3 N 4 Preparation of photocatalysts. Weigh 5 g of urea into a semi-closed crucible, transfer it into a muffle furnace and calcinate at 550 °C for 2 h with a heating rate of 15 °C / min, cool naturally to room temperature and grind to obtain g-C 3 N 4 Powder.

[0030]

Embodiment 3

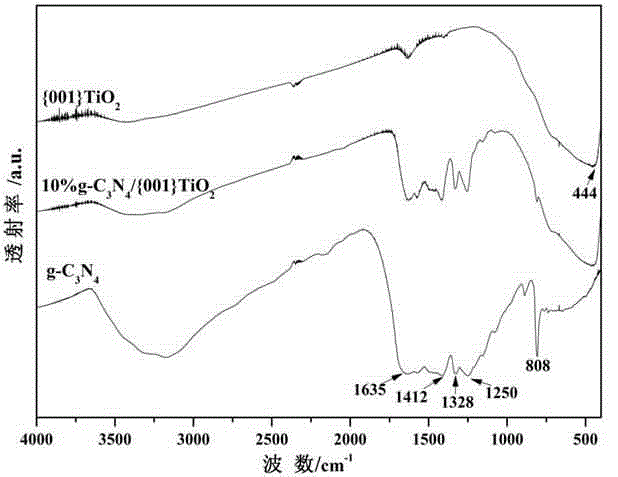

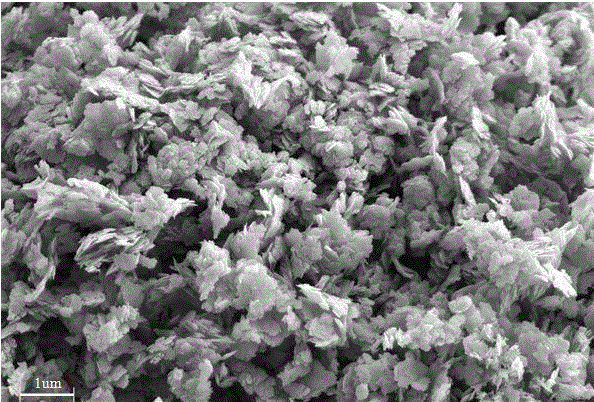

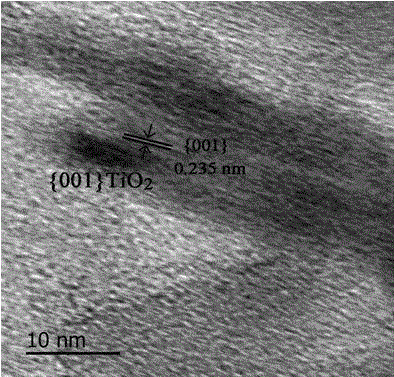

[0032] g-C 3 N 4 / {001}TiO 2 Preparation of composite photocatalyst: 0.1 g of {001}TiO as described in step (1) 2 The powder was mixed with 5 g of urea, and then the mixture was moved into a semi-closed crucible, placed in a muffle furnace and calcined in an air atmosphere for 2 h at a calcination temperature of 550 °C and a heating rate of 15 °C / min. 3 N 4 In situ growth on {001}TiO 2 surface( figure 1 , figure 2 ), to get the two-phase combined tightly ( image 3 ), and the visible light response ( Figure 4 ) g-C 3 N 4 / {001}TiO 2 composite photocatalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com