Process flow and treatment system for harmless treatment of sick and dead poultry and livestock

A technology for harmless treatment of sick and dead poultry and livestock, applied in the field of sick and dead poultry and livestock, can solve the problems of high energy consumption, high energy cost and inability to completely eliminate pollution sources in incineration treatment, so as to reduce occupied space and save energy The effect of consumption and improvement of chemical efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The harmless treatment process of sick and dead pigs consists of the following steps:

[0022] 1) Automatic feeding and crushing: the pig carcasses to be processed are transported to the knife box 2 through the electric conveyor belt 1, and the poultry carcasses are broken into mud by the rotation of the knife in the knife box 2, and then directly transported to the chemical barrel 3 , adding biological strains while crushing, the added amount accounts for 0.1% of the weight of the pig carcass, the knife box knife is the prior art, and its specific structure will not be described in detail;

[0023] 2) Heating treatment: heating by the burner 4, using the fan 5 to blow heat energy into the combustion furnace 6, making the hot air circulate in the combustion furnace 6, heating the medium oil in the combustion furnace 6, and the heated medium oil is in the chemical system The periphery of barrel 3 and the chamber of the combustion furnace circulate continuously; the mediu...

Embodiment 2

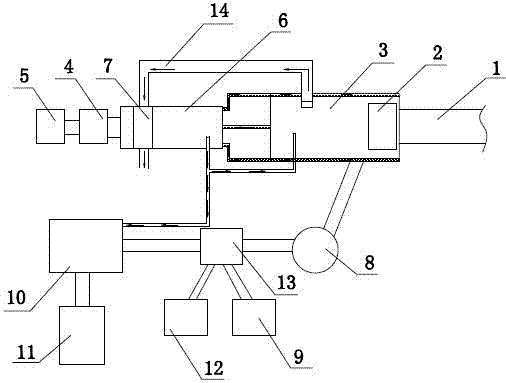

[0028] Such as figure 1 As shown, the treatment system used in the harmless treatment process of poultry and livestock includes a conveying system, a chopping device, a chemical barrel 3, a combustion system, an oil press, and a dryer. The combustion system includes a high-temperature fan 5 and a combustion furnace 6 , the combustion furnace is divided into upper and lower layers, the upper layer is provided with a ventilation pipe, the lower layer is provided with a water vapor chamber 7, the water vapor chamber 7 is connected to the ventilation pipe through a pipe, medium oil is injected into the gap between the ventilation pipes, and the exhaust gas is passed through the chemical machine. The pipeline is connected with the water vapor chamber in the combustion furnace, and the combustion furnace is respectively connected with the dryer and the chemical making machine through the hot air pipeline, and a hot oil circulation pipeline is arranged on the outer wall of the chemica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com