A method for seamless welding of ultra-high molecular weight polyethylene sheets

An ultra-high molecular weight, seamless welding technology, which is applied in the field of seamless welding of ultra-high molecular weight polyethylene sheets, can solve problems such as poor fluidity, difficulty, and high viscosity, and achieve uniform color, uniform weld joints, and good welding effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Such as Figure 1-4 shown.

[0035] A method for seamless welding of ultra-high molecular weight polyethylene sheets is applied to the processing of two ultra-high molecular weight polyethylene sheets, including the following steps:

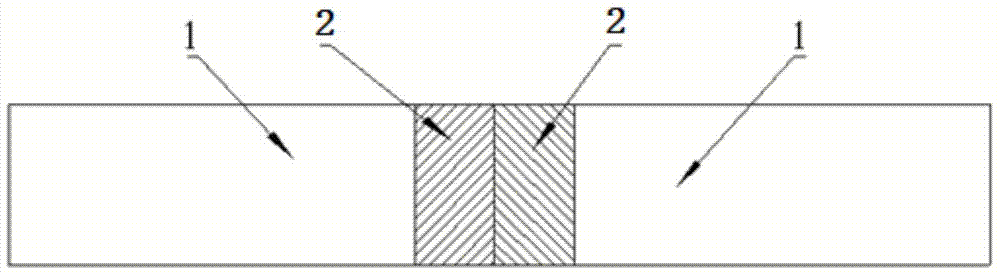

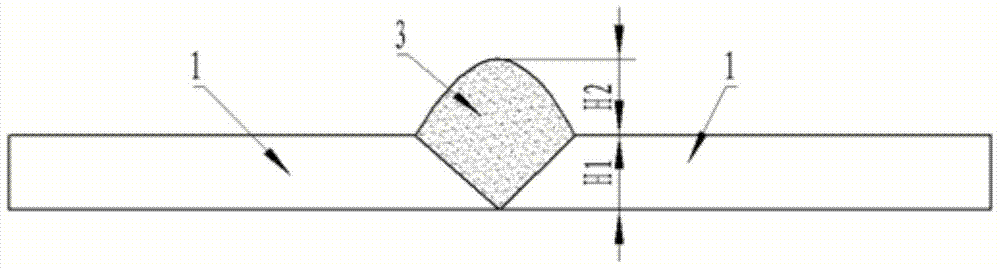

[0036] 1) Processing of the docking part; select two ultra-high molecular weight polyethylene sheets of 1500*5000*15mm made by the molding process, and groove the sides of the two UHMWPE sheets 1 with a length of 1500mm to be docked 2; the length of the groove 2 is 1500mm, the width is 10cm, and the slope is 40 degrees;

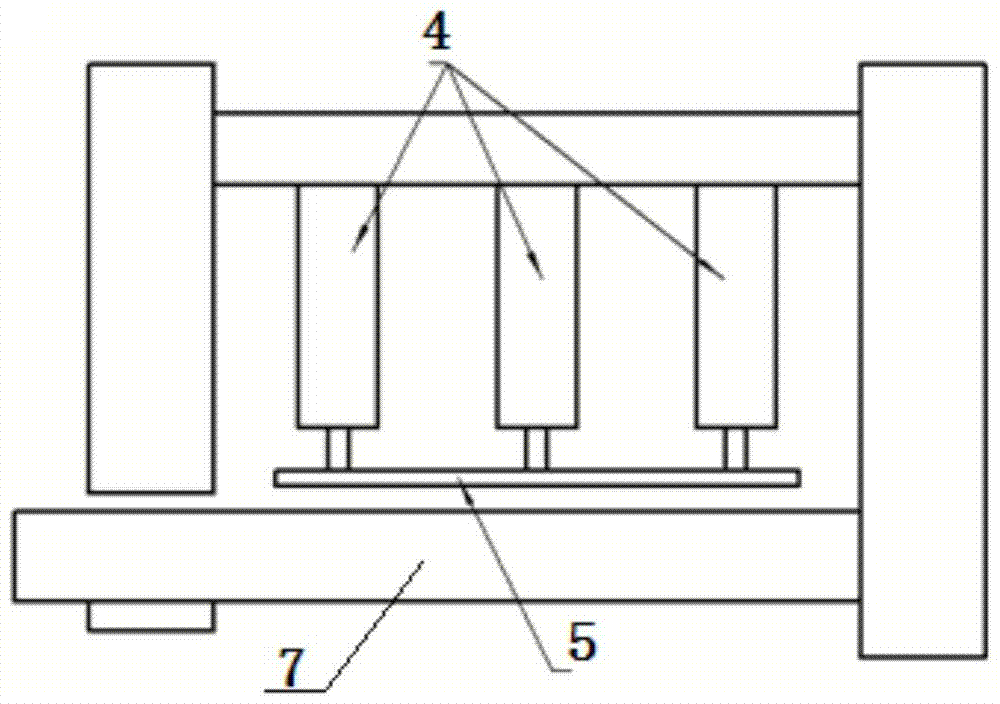

[0037] 2) Groove docking; two grooves 2 are butted on the hot-press welding equipment, and the groove 2 is filled with ultra-high molecular weight polyethylene plate powder 3 and is 10mm higher than the plate surface; the ultra-high molecular weight polyethylene The mass percentage of the components of the plate powder 3 is 16‰ of additives, 3‰ of color masterbatch, and the balance is ultra-high molecular weight polyeth...

Embodiment 2

[0043] Such as Figure 5-6 shown.

[0044] A method for seamless welding of ultra-high molecular weight polyethylene sheets as described in Example 1, the difference is that the method is applied to cylinder processing, and described step 1) is to use a piece of ultra-high molecular weight polyethylene sheet of 1500*5000*15mm The two sides of the molecular weight polyethylene sheet with a side length of 1500mm are beveled.

Embodiment 3

[0046]The method for seamless welding of ultra-high molecular weight polyethylene sheets as described in embodiment 1 or 2, the difference is that in the step 4), the specific process of cooling and increasing the pressure is to stop heating the butt joint 6 , boost the pressure to 12MPa, and cool with circulating water for 60 minutes. Circulating water cooling not only improves the cooling rate, but also is clean and pollution-free, and the circulating water saves resources.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com