Experimental method for preparation of poly-iron-based flocculating agent for coking wastewater advanced treatment

A technology for coking wastewater and advanced treatment, applied in the field of water treatment, can solve the problems of poor sweeping effect, slow settling speed, small flocs, etc., and achieve the effect of reducing load and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0055] Sampling water quality of coking wastewater: The water sample is taken from the coking secondary sedimentation tank of Benxi Iron and Steel Co., Ltd. The COD of the water sample is 240mg / L, the chromaticity is 170 times, and the turbidity is 84NTU.

[0056] Such as figure 1 As shown, an experimental method for the preparation of poly-iron-based flocculant for advanced treatment of coking wastewater, the specific operation steps are as follows:

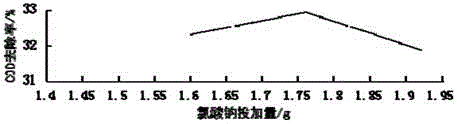

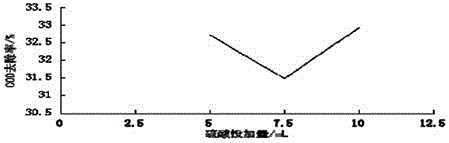

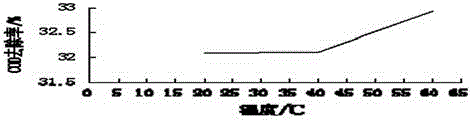

[0057] 1.1 Preparation of polyferric sulfate

[0058] This part of the experiment is to use ferrous sulfate heptahydrate, sodium chlorate and sulfuric acid to prepare polyferric sulfate flocculant. In the experiment, by controlling the three conditions of temperature, dosage of sulfuric acid and sodium chlorate, the optimal preparation conditions were determined by the method of orthogonal experiment. Because my country's "Water Purifier Polyferric Sulfate (GB14591-2006)" stipulates that the total iron content of polyferric su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decolorization rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com