High resistant starch (RS3) content product prepared through autoclaving treatment and enzymatic debranching and preparation method thereof

A technology of resistant starch and debranching, applied in the field of food processing, can solve the problems of low yield of resistant starch, complicated production process, low efficiency, etc., and achieve the effects of low cost, clean production process and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0070] Embodiment 1: control sample preparation method:

[0071] The raw sweet potato starch was prepared with distilled water to obtain a sweet potato starch suspension with a concentration of 25wt%, autoclaved at 121° C. for 40 minutes, and cooled to room temperature;

[0072] The pH of the starch paste was adjusted to 2 with 2M hydrochloric acid for 1 hour, then aged at 4 °C for 24 hours, then dried at 60 °C for 48 hours, pulverized with a universal pulverizer, and passed through an 80-mesh standard sieve to obtain a control sample .

Embodiment 2

[0073] Example 2: Preparation of Resistant Starch Product A - Method 1

[0074] 1. Prepare a sweet potato starch suspension with a concentration of 25wt% from the raw sweet potato starch with distilled water, carry out autoclaving at 121°C for 40 minutes, the pressure is 0.1-0.3MPa, and cool the starch paste to 60°C;

[0075] 2. Adjust the pH of the starch paste to 6 with 2M hydrochloric acid, add 20 ASPU / g starch pullulanase, and then hydrolyze at 60°C for 12 hours;

[0076] 3. Cool the hydrolyzed starch milk to room temperature, adjust the pH of the starch paste to 2 with 2M hydrochloric acid, leave it at room temperature for 1 hour to kill the enzyme, and then store it at 4°C for 24 hours (this is the aging treatment step, the same below). ), then dried at 60° C. for 48 hours, pulverized with a universal pulverizer, and passed through an 80-mesh standard sieve to obtain a resistant starch product A.

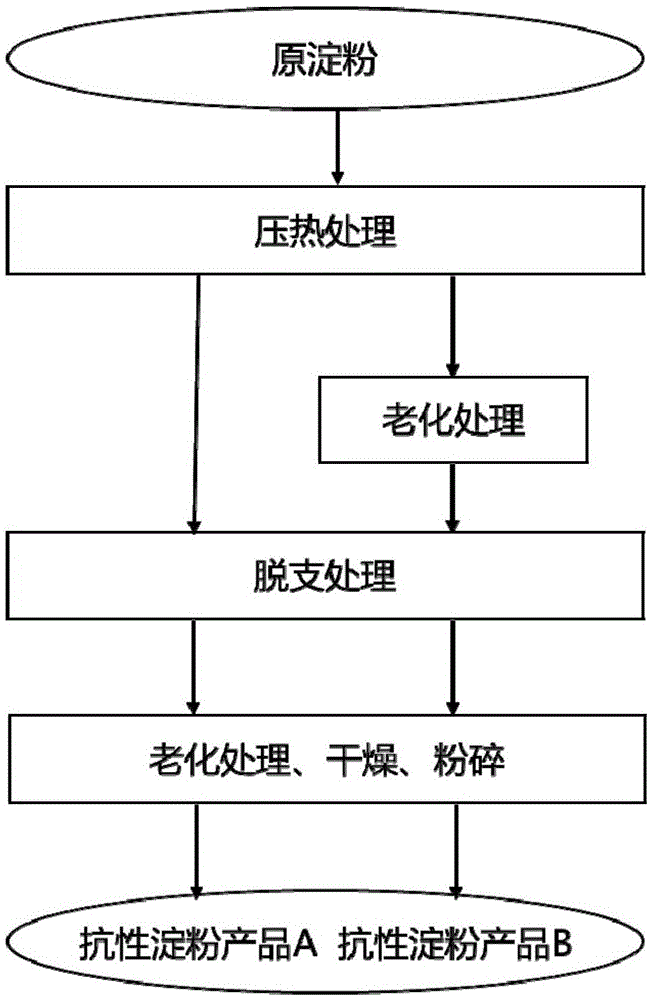

[0077] Its process flow chart see figure 1 .

Embodiment 3

[0078] Example 3: Preparation of Resistant Starch Product A - Method 2

[0079] 1. Prepare a sweet potato starch suspension with a concentration of 20 wt % by using distilled water to prepare a sweet potato starch suspension, perform autoclaving at 121° C. for 30 minutes, at a pressure of 0.1-0.3 MPa, and cool the starch paste to 60° C.;

[0080] 2. Adjust the pH of the starch paste to 5.5 with 2M hydrochloric acid, add 22 ASPU / g starch isoamylase, and then hydrolyze at 60°C for 12 hours;

[0081] 3. Cool the hydrolyzed starch milk to room temperature, adjust the pH of the starch paste to 2 with 2M hydrochloric acid, leave it at room temperature for 1 hour to kill the enzyme, and then store it at 4°C for 24 hours (this is the aging treatment step, the same below). ), then dried at 60° C. for 48 hours, pulverized with a universal pulverizer, and passed through an 80-mesh standard sieve to obtain a resistant starch product A.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com