Cable capable of shielding electromagnetic wave and preparing method for copper iron alloy of cable

A copper-iron alloy, electromagnetic wave technology, used in cable/conductor manufacturing, insulated cables, cables, etc., can solve the problems of common mode noise, magnetic waves cannot have obvious effects, etc., and achieve the effect of improving the effect, beautiful appearance and light weight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

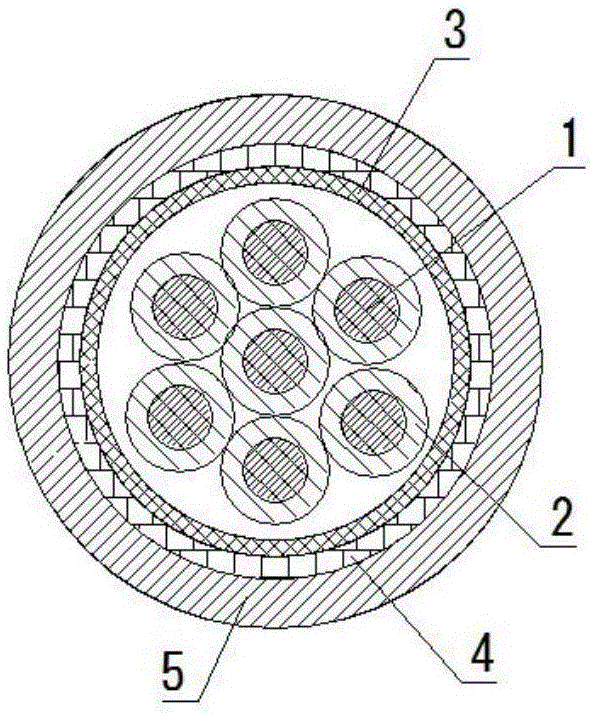

[0020] Such as figure 1 As shown, the electromagnetic wave shielding cable made of copper-iron alloy includes a conductor 1 , an insulator 2 , a constraint layer 3 , a shielding material 4 , and a protective layer 5 . Constraint layer 3 is composed of aluminum foil and polyester tape and sheet tape.

[0021] A plurality of conductors 1 are bundled together after being surrounded by respective insulators 2 . The enclosed plurality of conductors 1 are enclosed by a constraining layer 3 and surrounded by a braided copper-iron alloy wire mesh or a sheet-type shielding material layer 4 . The layer 4 of shielding material is then surrounded by a protective layer 5 .

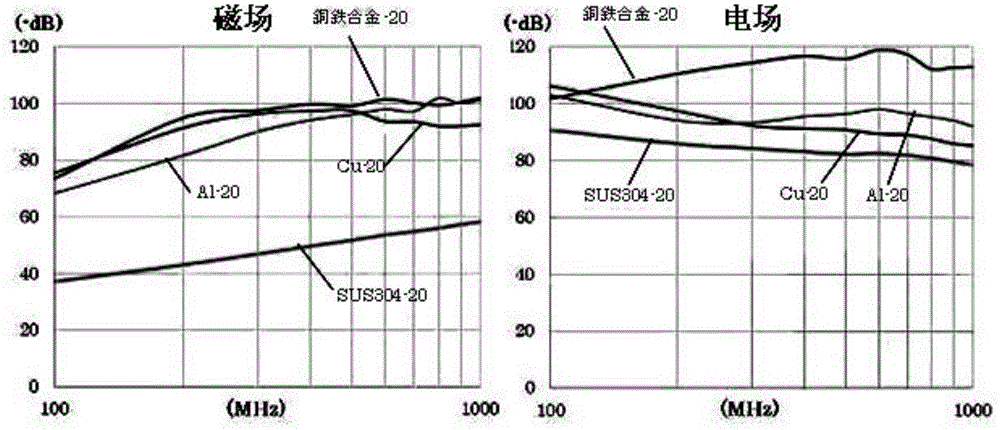

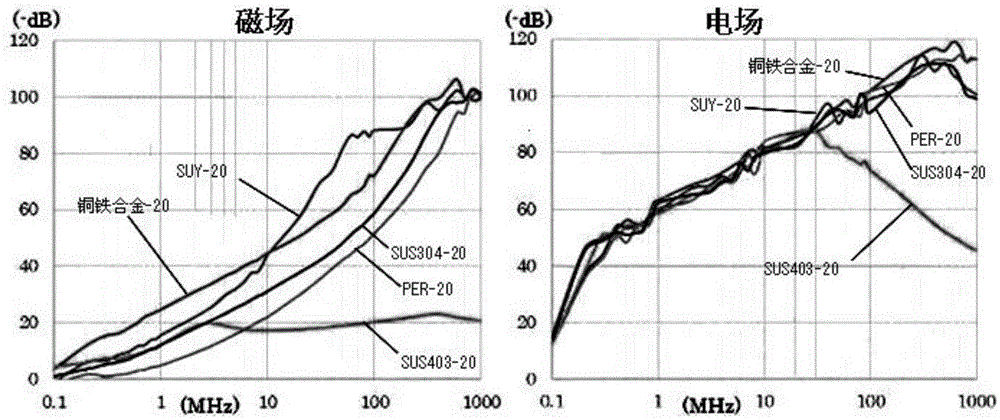

[0022] The characteristic of the cable is that on the conductor wrapped by the insulator, there are tiny crystal grains in the copper matrix, which are mainly composed of iron, and the content of iron is 5-45% of the total weight of the alloy. , constitute a copper-iron alloy mesh shielding material with a wire diam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com