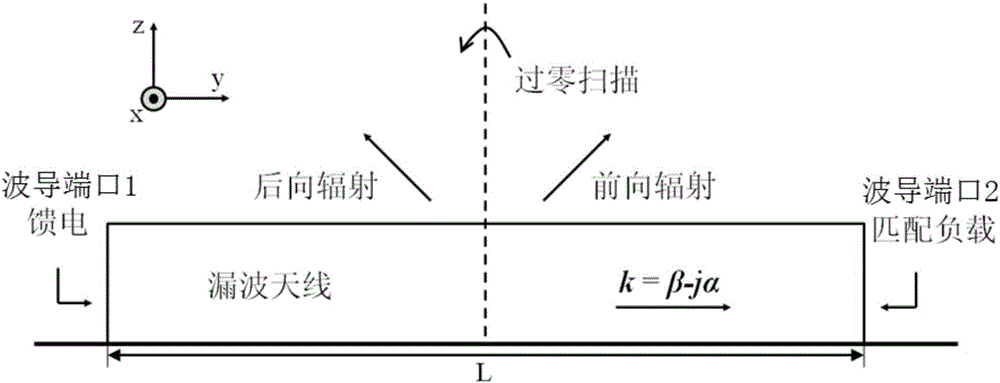

Liquid crystal electric control zero crossing scanning leaky-wave antenna based on half-mode pectinate line waveguide

A leaky-wave antenna and comb-line technology, which is applied in the field of microwave antenna engineering, can solve problems such as difficult zero-crossing scanning and electronically controlled scanning leaky-wave antennas are difficult to work, and achieve the effects of large power capacity, low loss, and improved radiation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

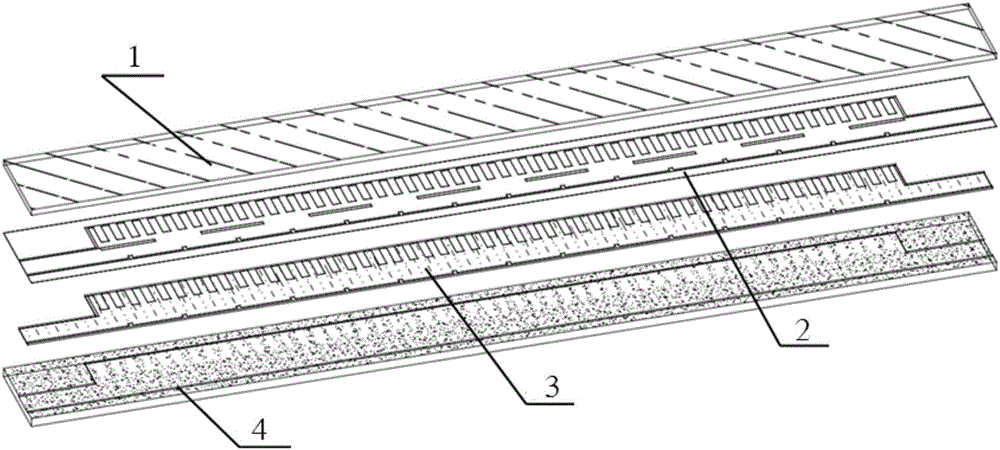

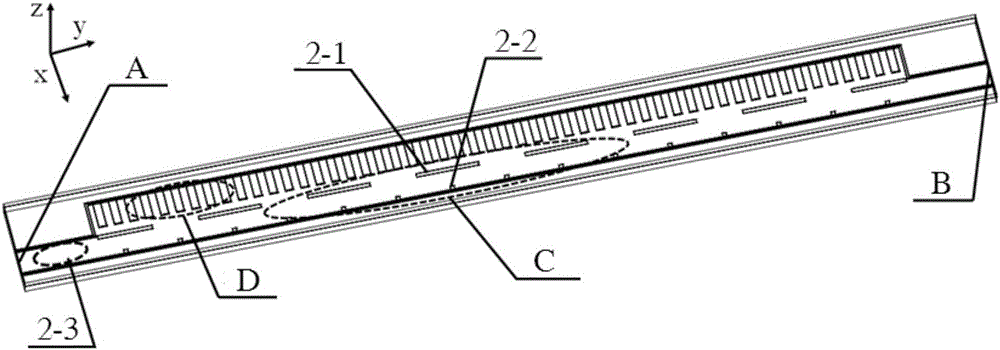

[0029] Specific implementation mode one: the following combination Figure 2 to Figure 5 Describe this embodiment mode. The liquid crystal electronically controlled zero-crossing scanning leaky wave antenna based on the half-mode comb line waveguide described in this embodiment mode includes a top dielectric plate layer 1, a metal layer 2, a liquid crystal layer 3 and a bottom waveguide groove 4;

[0030] A metal layer 2 is arranged between the top dielectric plate layer 1 and the bottom waveguide groove 4, and the bottom waveguide groove 4 is a rectangular plate with a longitudinal groove structure on the upper surface, and a liquid crystal layer 3 is arranged in the longitudinal groove;

[0031] The top dielectric plate layer 1 and the metal layer 2 are tightly integrated into one body through mechanical processing, electroplating, hot pressing or microelectronic technology;

[0032] The bottom waveguide groove 4 is a rectangular plate with a vertical groove structure on the...

specific Embodiment approach 2

[0040] The external dimensions of the bottom waveguide groove 4 are not limited, and the longitudinal grooves on the bottom waveguide groove 4 are made by mechanical processing, microelectronics technology or electroplating technology. m ×a LC × d LC Tank body, take the slot width a LC >λ / 2, λ is the working wavelength, groove depth d LC image 3 in the z direction. Above the liquid crystal is a metal layer. Since the width of the comb line structure is smaller than that of the waveguide groove, the metal layer and the waveguide groove are electrically isolated. Therefore, the connection between the metal layer and the waveguide does not require direct connection and sealing with insulating glue. Specific implementation mode two: the following combination Figure 6 to Figure 12 This implementation mode is described, and the antenna structure of the first implementation mode is further described in this implementation mode in combination with specific examples.

[0041] As...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com