Adhesive sheet and method for producing processed device-related parts

A technology related to equipment and components, applied in the direction of non-polymer adhesive additives, semiconductor/solid-state device manufacturing, adhesive additives, etc. Problems such as resistance, to achieve the effect of reducing adhesion, manufacturing productivity, and suppressing outgassing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0115] (1) Preparation of coating composition

[0116] A solution-state coating composition (solvent: toluene) having the following composition was prepared.

[0117] i) As a polymer (A) having a polymerizable functional group, a copolymer obtained by copolymerizing 52 parts by mass of butyl acrylate, 20 parts by mass of methyl methacrylate, and 28 parts by mass of hydroxyethyl acrylate (weight-average molecular weight: 600,000, glass transition temperature Tg: -34°C), a combination of 2-methacryloyloxyethyl isocyanate in an amount corresponding to 80 mol% of the hydroxyl groups contained in the copolymer (manufactured by Showa Denko, KARENZ MOI) was reacted, and the obtained polymer was calculated as 100 parts by mass,

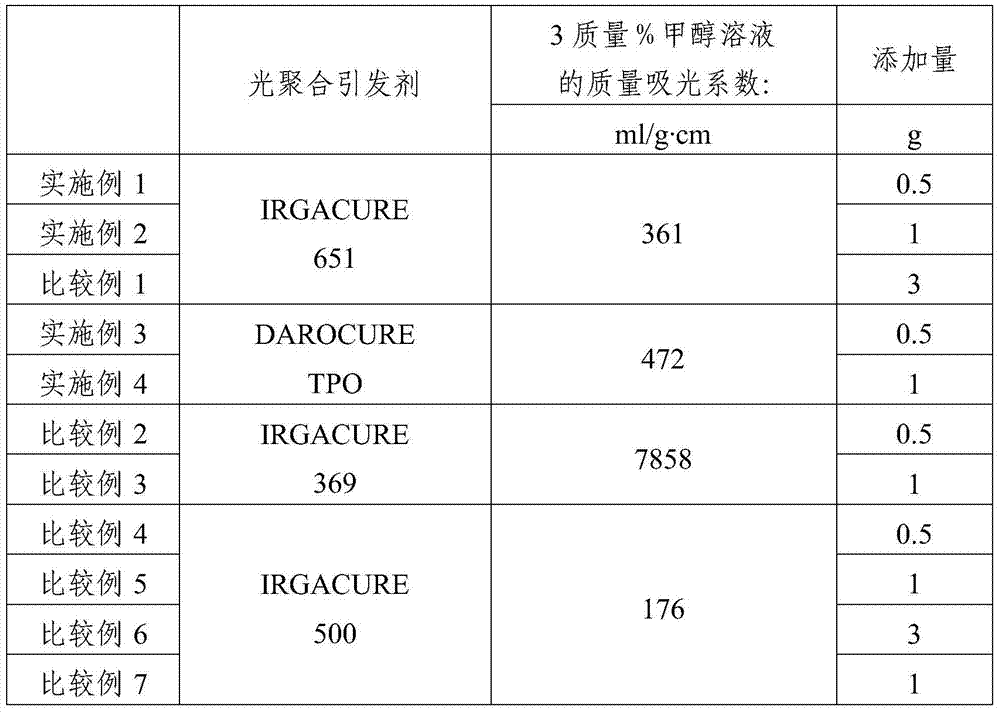

[0118] ii) As the photopolymerization initiator (B), a composition containing 2,2-dimethoxy-1,2-diphenylethan-1-one (manufactured by BASF, IRGACURE 651, at 3% by mass The mass absorption coefficient of wavelength 365nm under the state of methanol solution: ...

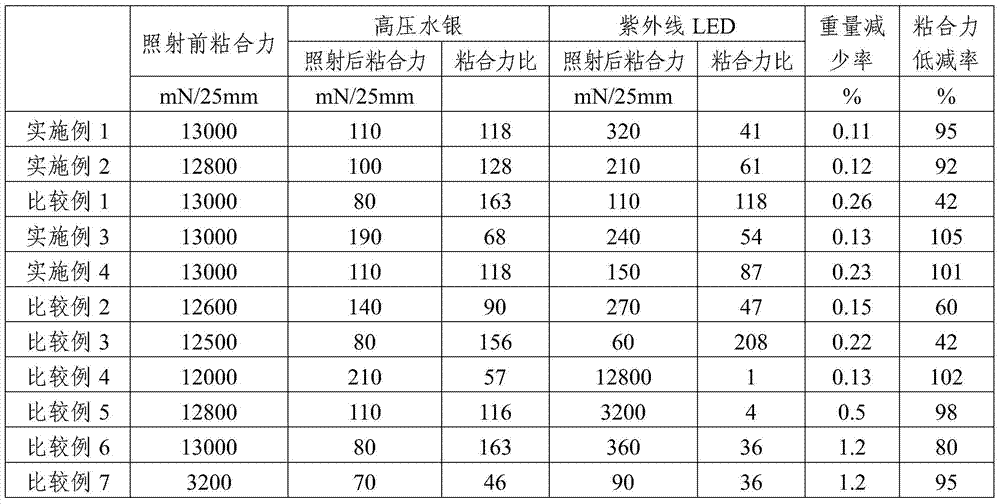

Embodiment 2~3 and comparative example 1~6

[0124] In Example 1, either one or both of the kind and the added amount of the photopolymerizable compound (B) were changed as shown in Table 1, and a pressure-sensitive adhesive sheet was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile stress | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com