Photocurable adhesive, polarizing plate using same, multilayer optical member and liquid crystal display device

A light-curable and adhesive technology, applied in adhesives, polarizing elements, optical elements, etc., can solve problems such as easy to cause deterioration, high moisture permeability, and insufficient adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

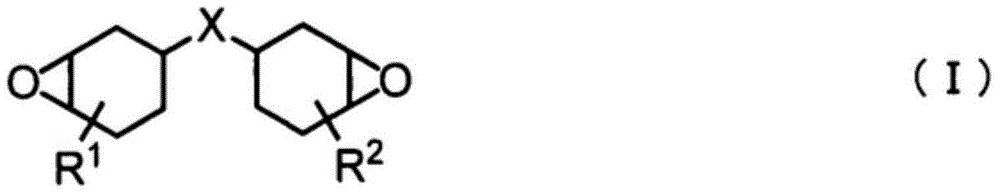

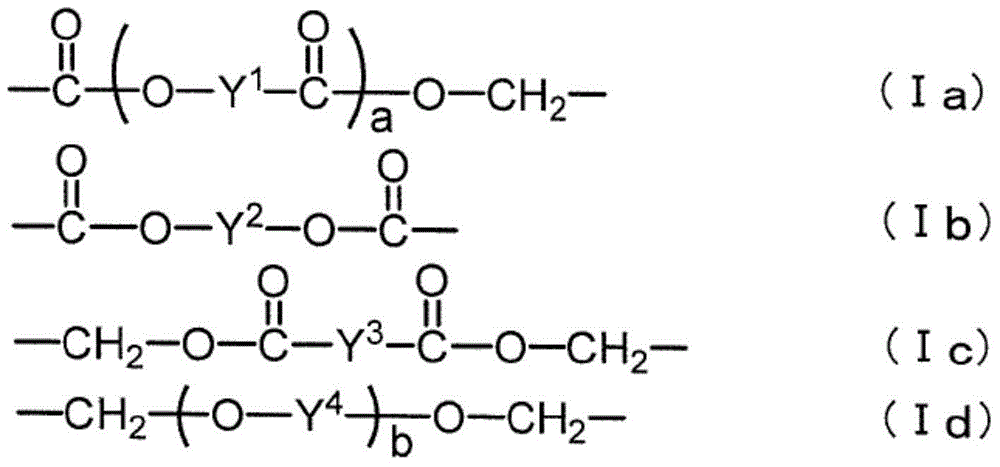

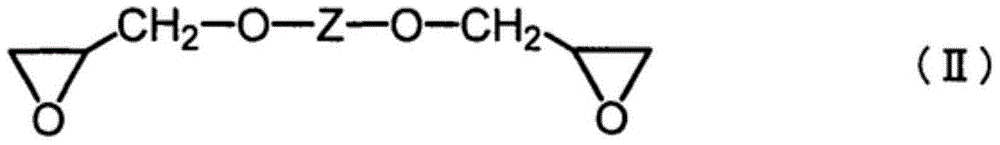

Method used

Image

Examples

Embodiment 1~14 and comparative example 1

[0243] (1) Preparation of photocurable adhesive

[0244] After mixing the above components, defoaming was performed to prepare photocurable adhesives (liquid) of Examples 1 to 14 and Comparative Example 1. In Table 1, the compounding ratio (unit: part) of each component is shown using a symbol. Furthermore, the photocationic polymerization initiator (b1) was actually compounded as a 50% propylene carbonate solution, and in Table 1, the compounding ratio was shown by the solid content amount.

[0245] [Table 1]

[0246]

(a1)

(a2)

(a2′)

(a3-I)

(a3-II)

(a3-III)

(a4-I)

(a4-II)

(b1)

Example 1

32

55

13

2.25

Example 2

32

55

13

2.25

Example 3

32

55

13

2.25

Example 4

25

50

20

5

2.25

Example 5

25

50

20 ...

Embodiment 15~25 and comparative example 6~7

[0276] Examples 15 to 25 and Comparative Examples 6 to 7 are shown below, which are prepared using an adhesive solution in which water or a diol compound is added to (A) a photocation curable component and (B) a photocation polymerization initiator. Examples of polarizing plates. In addition, in Examples 15-25 and Comparative Examples 6-7, the same thing as what was shown before was used for (A) photocation curable component and (B) photocation polymerization initiator. In addition, the moisture and the diol compound used in Examples 15-25 and Comparative Examples 6-7 are as follows.

[0277] 〈Moisture〉

[0278] purified water

[0279]

[0280] (c1) Ethylene glycol

[0281] (c2)1,2-Propanediol

[0282] (c3)1,4-Butanediol

[0283] (1) Preparation of photocurable adhesive

[0284] After mixing the above components, defoaming was performed to prepare photocurable adhesives (liquid) of Examples 15-25 and Comparative Examples 6-7. In Table 3, the compounding ratio (unit: p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Peel force | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com