Pig tongue preparation method

A tongue and pig tongue technology, which is applied in the field of pig tongue preparation, can solve problems such as inconvenient storage, transportation and carrying, uneven quality of pig tongue products, obstacles to product sales and storage, etc., and achieve convenient transportation, unique flavor and long-lasting The effect of shelf life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

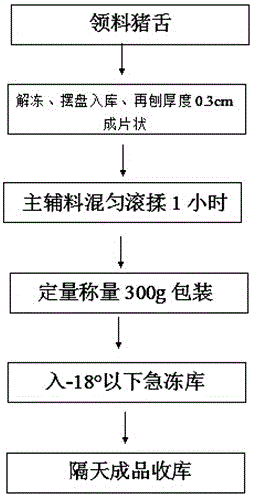

Image

Examples

Embodiment 1

[0020] In the embodiment of the present invention, a preparation method of pig tongue, 500 kg of pig tongue raw material is thawed after picking, placed on a plate and stored in a warehouse, and then sliced with a slicer, with a thickness of 0.2-0.4 cm. After complete thawing, pour it into the tumbler and first add B ingredients and tumble for 1.5 hours, then add A ingredients and tumble for 1 hour, then add 500ml of sorghum wine and 24kg of edible modified starch and stop when it is evenly stirred. The tumbling speed is 12r / min. Among them, ingredients A include: 1200g edible salt, 550g white sugar, 250g food powder, 250g loose meat powder, 70g terriphos crisp, 70g terphosphorus, 190g D-isoascorbic acid; B ingredients include: 3.5kg monosodium glutamate, meat paste 0.5kg, pepper powder 1.7kg, Beijing shochu 1.1kg, water 330kg. The moisture in B ingredients is added twice, and crushed ice is needed in summer. During the assembly line operation of the quantitative packaging ...

Embodiment 2

[0022] In the embodiment of the present invention, a preparation method of pig tongue, 500 kg of pig tongue raw material is thawed after picking, placed on a plate and stored in a warehouse, and then sliced with a slicer, with a thickness of 0.2-0.4 cm. After complete thawing, pour it into the tumbler, first add B ingredients and tumble for 1.5 hours, then add A ingredients and tumble for 1 hour, then add 600ml of sorghum wine, 26kg of edible modified starch and stir evenly, stop when the tumbling speed is 12r / min. Among them, ingredients A include: 1400g of edible salt, 650g of white sugar, 350g of food powder, 350g of loose meat powder, 90g of terriphos, 90g of terphos, and 210g of D-isoascorbic acid; ingredients of B include: 3.7kg of monosodium glutamate, meat paste 0.7kg, pepper powder 1.9kg, Beijing shochu 1.3kg, water 350kg. The moisture in B ingredients is added twice, and crushed ice is needed in summer. During the assembly line operation of the quantitative packag...

Embodiment 3

[0024] In the embodiment of the present invention, a preparation method of pig tongue, 500 kg of pig tongue raw material is thawed after picking, placed on a plate and stored in a warehouse, and then sliced with a slicer, with a thickness of 0.2-0.4 cm. After complete thawing, pour it into the tumbler, first add B ingredients and tumble for 1.5 hours, then add A ingredients and tumble for 1 hour, then add 500-600ml of sorghum wine, 24-26kg of edible modified starch and stop when it is evenly stirred, and the tumbling speed is 12r / min. The ingredients of A include: 1300g of edible salt, 600g of white granulated sugar, 300g of food powder, 300g of loose meat powder, 80g of Tellyphos crispy, 80g of terphosphorus, and 200g of D-isoascorbic acid. B ingredients include: ingredients MSG 3.6kg, meat paste 0.6kg, pepper 1.8kg, Beijing shochu 1.2kg, water 340kg. The moisture in B ingredients is added twice, and crushed ice is needed in summer. During the assembly line operation of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com