Preparation method and application of ultrasonic impregnation modified resin

A modified resin and ultrasonic impregnation technology, applied in the field of water treatment, can solve problems such as increasing the difficulty of removing nitrate, and achieve the effects of easy regeneration and repeated use, simple preparation process and excellent removal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A preparation method for ultrasonic impregnation modified resin, comprising the following steps:

[0029] (1) Take a certain volume of fresh resin, add it to 5% to 20% sodium chloride solution at a volume ratio of 1:5 and soak for 2 to 6 hours, then rinse it with deionized water until it is colorless, and dry it naturally to constant weight reserve;

[0030] (2) Weigh the pretreated resin obtained in step (1), and KMnO with a concentration of 2.0g / L~15.0g / L 4 The solution was mixed and impregnated at a volume ratio of 1:2 to 5, and stirred rapidly for 2 hours; then washed and filtered with deionized water until the filtrate was colorless;

[0031] (3) Add the impregnated resin obtained in step (2) to 85.0g / L~176.3g / L FeSO at a volume ratio of 1:2~5 4 ·7H 2 O solution, sealed and ultrasonically impregnated for 30min to 60min, after full reaction, alternately rinsed three times with 1% sodium bicarbonate solution and deionized water, then quickly rinsed with deionized ...

Embodiment 2

[0034] Ultrasonic impregnation modified resin of the present invention is used for processing the nitrate in water body, comprises the following steps:

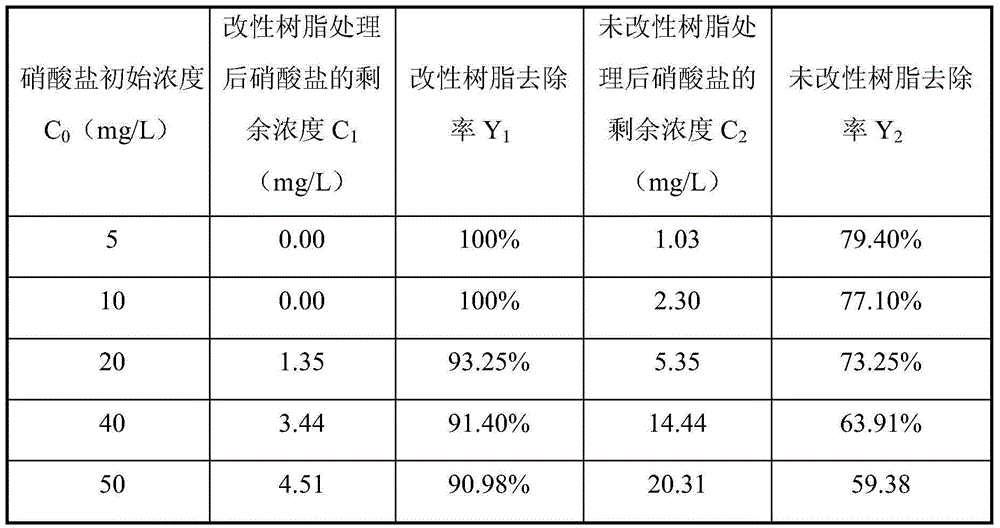

[0035] The ultrasonic impregnation modified resin prepared in Example 1 was added to 5 groups of 250mL nitrate water bodies with initial concentrations of 5mg / L, 10mg / L, 20mg / L, 40mg / L and 50mg / L respectively, and ultrasonic impregnation The dosage of the modified resin is 0.2g, the initial pH value of the water body is 7.0±0.2, and the constant temperature oscillation reaction is carried out in a water bath at 25°C. After 12 hours, the material is separated from the water body with filter paper, and the ion chromatography is used to The remaining nitrate concentration in the water was measured, and the removal rate of nitrate was calculated. The results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com