Thermocouple welding device

A welding device and thermocouple technology, applied in welding equipment, welding equipment, auxiliary equipment, etc., can solve the problems that graphite electrodes are easy to contaminate thermocouples, made into different shapes, and unsuitable for use, so as to reduce heat conduction errors and reduce dynamics. Effect of response error and improvement of temperature measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

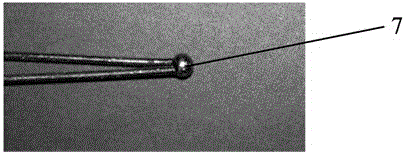

[0049] In this embodiment, the selected thermocouple pole materials are platinum-rhodium 6 and platinum-rhodium 30 alloy wires respectively, and the specifications are both Φ0.5*50mm. And compare the thermocouple made by the existing salt water welding method with the thermocouple made by adopting the thermocouple welding device of the present invention.

[0050] image 3 The thermocouple obtained by salt water welding is shown, the diameter of the welding point is 1.5mm, and it is difficult to change the shape of the thermocouple when the two poles are arranged side by side;

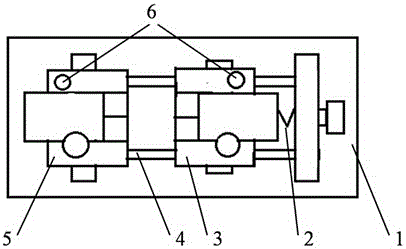

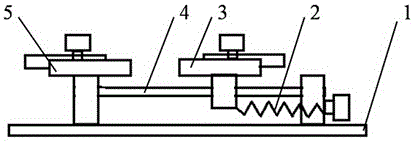

[0051] Figure 4 Shown is the thermocouple made by using the thermocouple welding device of the present invention. The diameter of the welding point is 0.5mm, and the size of the welding point is only one-third of the original welding method, which can significantly reduce the heat conduction error and dynamic response error. Linear thermocouples can be made according to different needs to meet the nee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com