Self-adaptive adjusting method based on multi-degree-of-freedom adjusting mechanism of grinded/polished workpieces

A technology of self-adaptive adjustment and adjustment mechanism, applied in grinding machine tools, grinding tools, grinding/polishing equipment, etc., can solve problems such as poor surface flatness, and achieve correction of workpiece pose information, improve processing effect, and improve workpiece processing. quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with accompanying drawing:

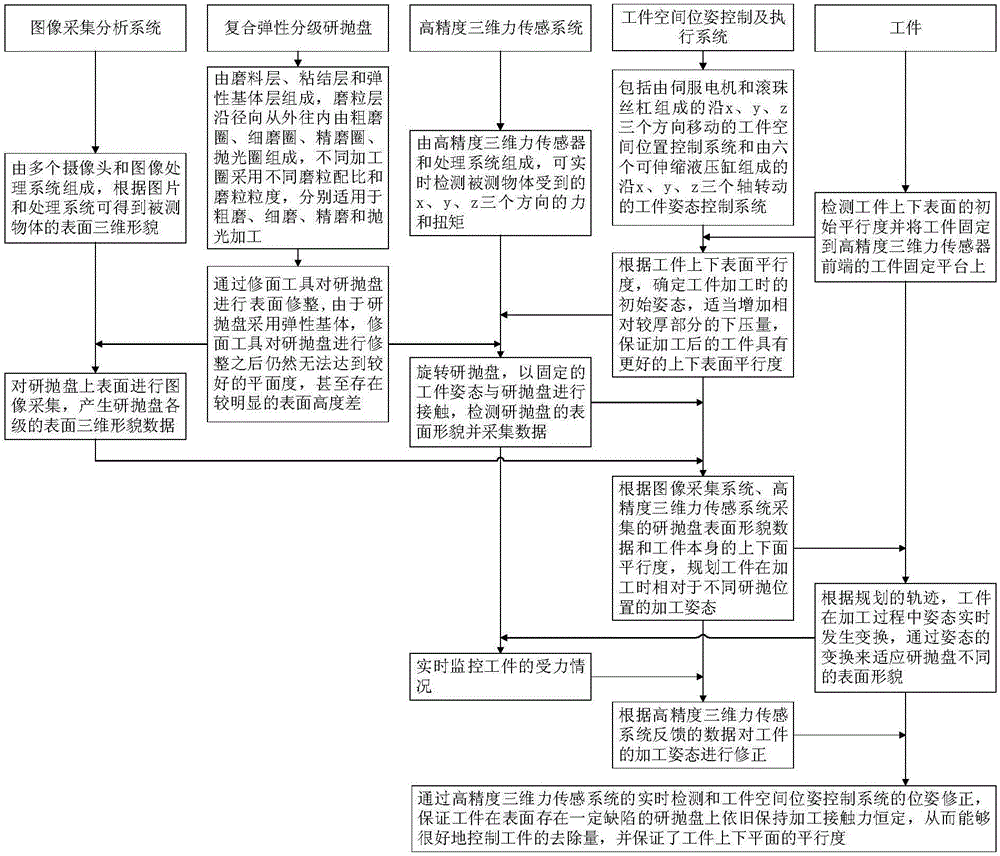

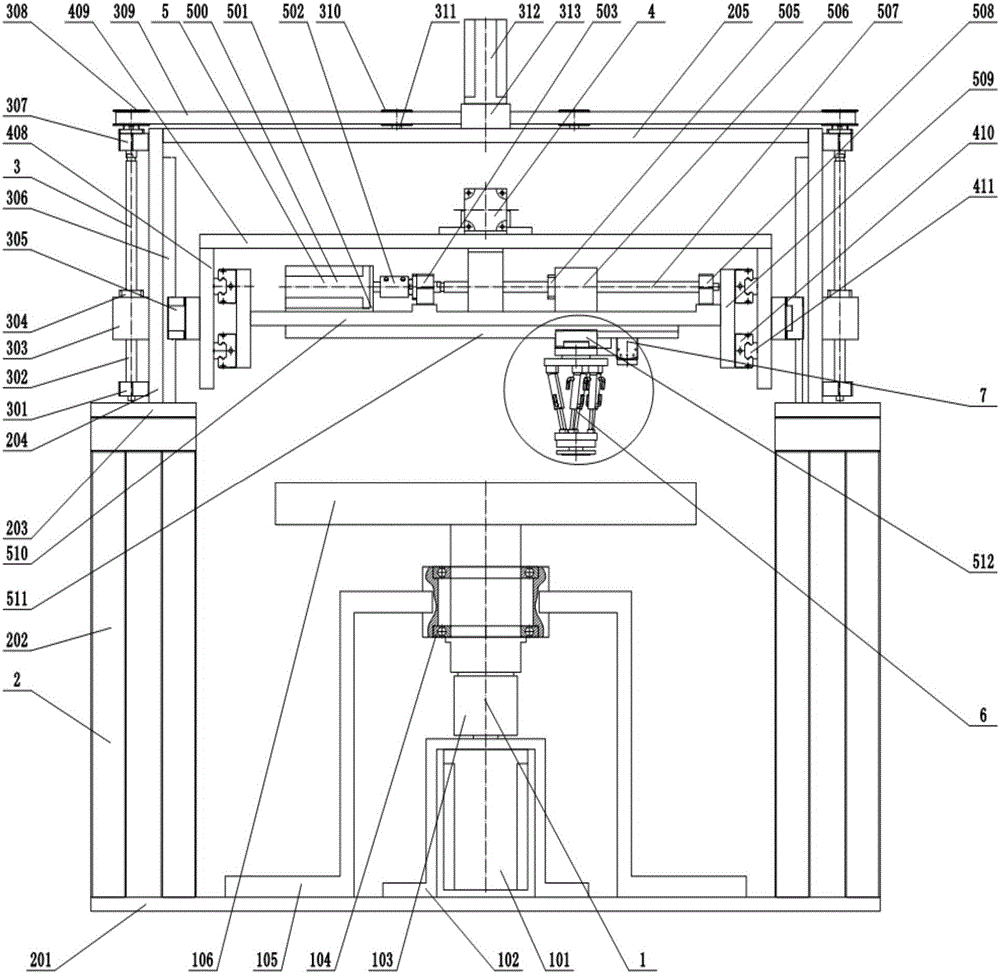

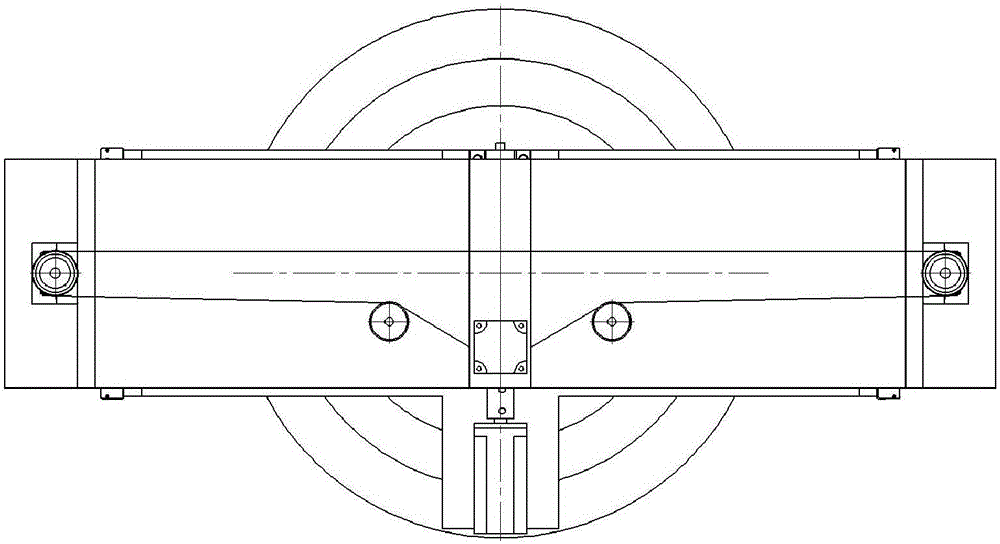

[0024] Such as Figure 1~6 As shown, the adaptive adjustment method based on the multi-degree-of-freedom adjustment mechanism for grinding and polishing workpieces includes the following steps: provide the workpiece, measure the parallelism of the upper and lower surfaces of the workpiece, and fix the workpiece on the workpiece fixing platform at the front end of the high-precision three-dimensional pressure sensor Above; provide a composite elastic graded polishing disc, and trim the upper surface of the graded polishing disc through a shaving tool; use an image acquisition and analysis system to collect images of the surface of the graded polishing disc and generate three-dimensional topography data on the surface of the graded polishing disc, and at the same time, through a fixed attitude The workpiece is in contact with the rotating graded polishing disc, and the force ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com