Catalytic curing type 3D printing technology and printer

A 3D printing and printer technology, applied in the field of 3D printing technology, can solve the problems of inability to apply multiple materials, single material, poor color, etc., and achieve the effect of good overall effect, high density, and not easy to damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

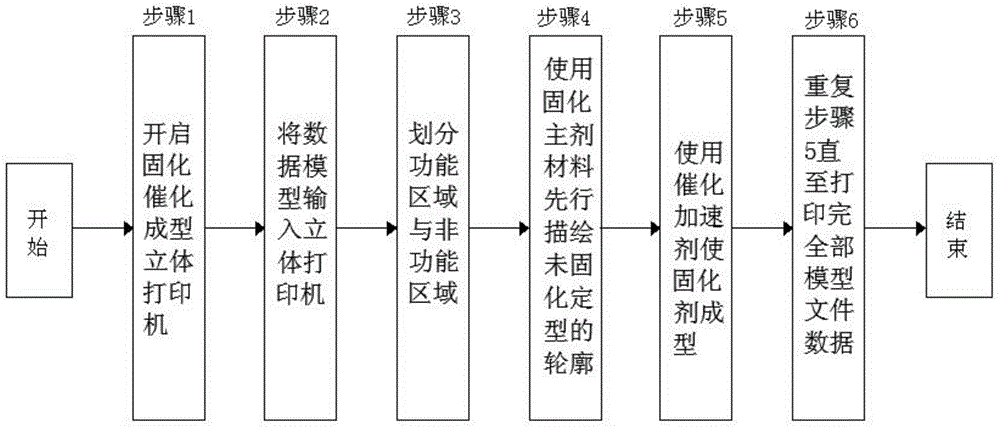

Method used

Image

Examples

Embodiment 1

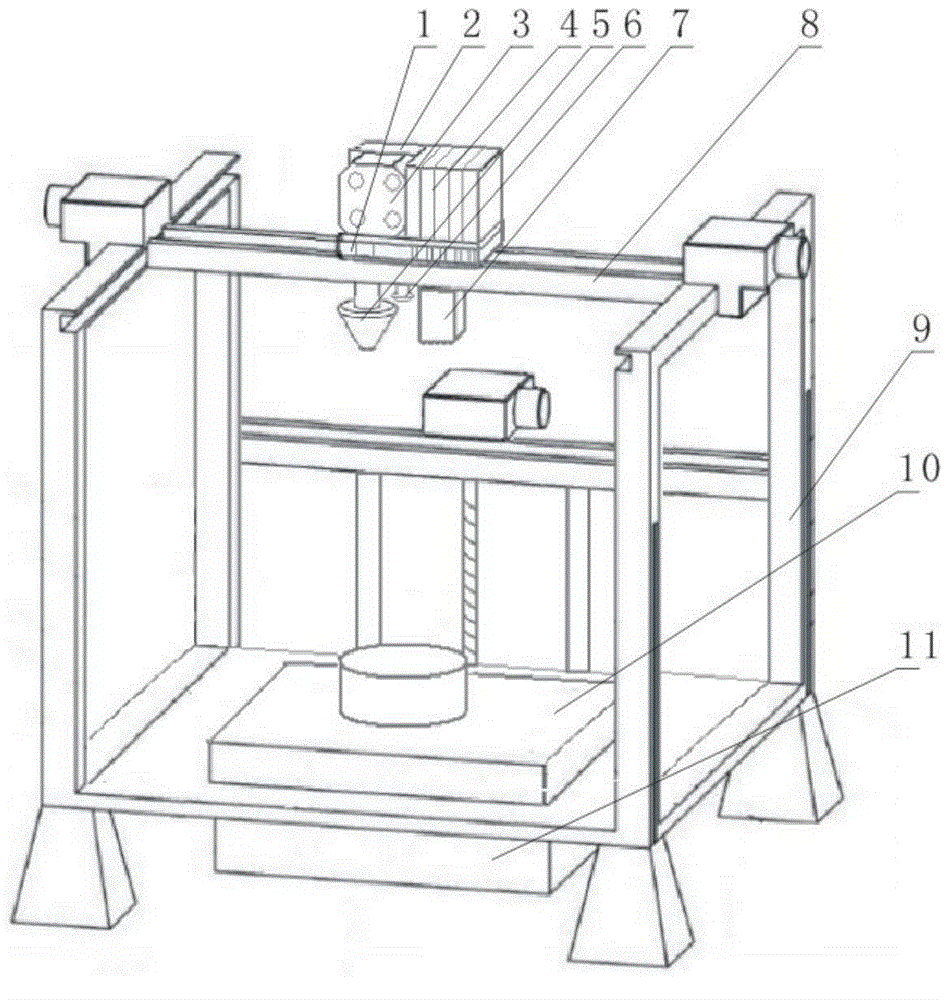

[0067] A three-dimensional printer for curing catalytic molding, comprising a frame 9, a loading platform 10, a control box 11, a mobile platform 1, a curing main agent ejection head 5, a curing main agent container 3, an ejection device 2, and a catalytic accelerator nozzle 7 And the catalytic accelerator container 4, the loading platform for carrying the model is installed on the bottom of the frame, the control box is installed at the lower end of the loading platform, and the processor of the printer is installed in the control box; the corresponding frame upper part above the loading platform drives A mobile platform is installed, and the mobile platform can be raised, lowered and moved horizontally on the rack under the control of the processor;

[0068] For the specific installation structure of the mobile platform, see the attached figure 2 As shown, the frame 9 is a cube-shaped frame, and a crossbeam 8 arranged horizontally and horizontally is installed on the upper ...

Embodiment 2

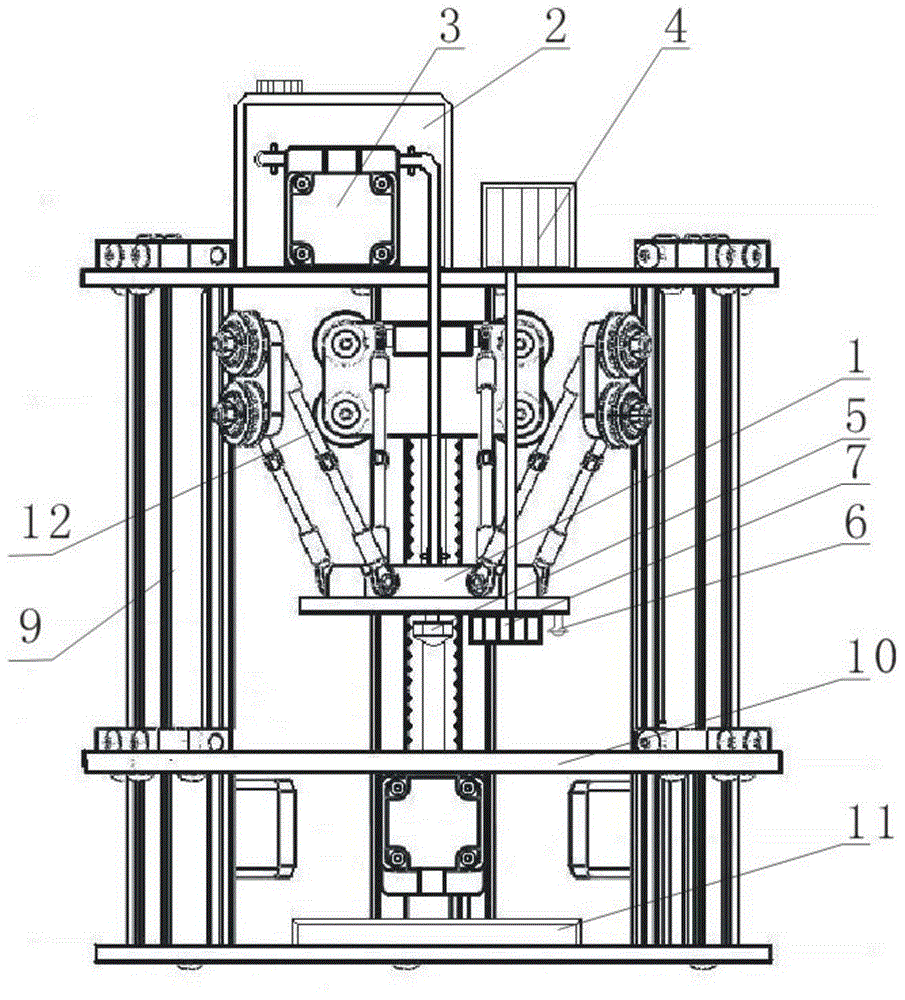

[0075] A three-dimensional printer for curing catalytic molding, comprising a frame 9, a loading platform 10, a control box 11, a mobile platform 1, a curing main agent ejection head 5, a curing main agent container 3, an ejection device 2, and a catalytic accelerator nozzle 7 and the catalyst accelerator container 4,

[0076] A loading platform for carrying the model is installed at the lower part of the frame, and the loading platform is set horizontally. A control box is installed under the loading platform, and the processor of the printer is installed in the control box; the corresponding upper part of the rack above the loading platform drives A mobile platform is installed, and the mobile platform can be raised, lowered and moved horizontally on the rack under the control of the processor;

[0077] For the specific installation structure of the mobile platform, see the attached image 3 As shown, the frame of the present embodiment is a triangular prism-shaped three-di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com