Lightweight chassis structure of low-floor electric coach

An electric bus and low-floor technology, applied in the substructure, vehicle components, transportation and packaging, etc., can solve the problems of difficult structural design of aluminum alloy chassis, complex layout space and working space, and complex chassis system space, etc. Simple, low-cost, and easy-to-manufacture effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be described in detail below in conjunction with the accompanying drawings.

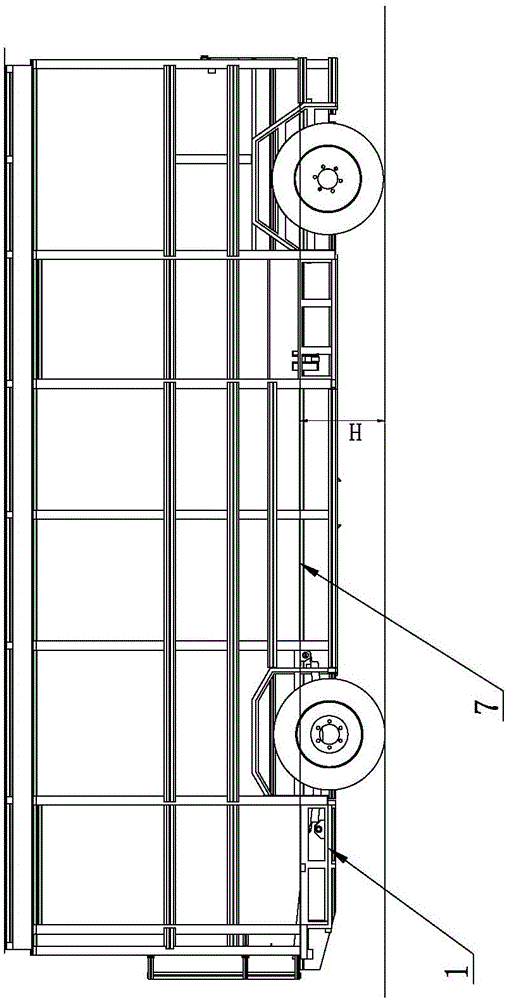

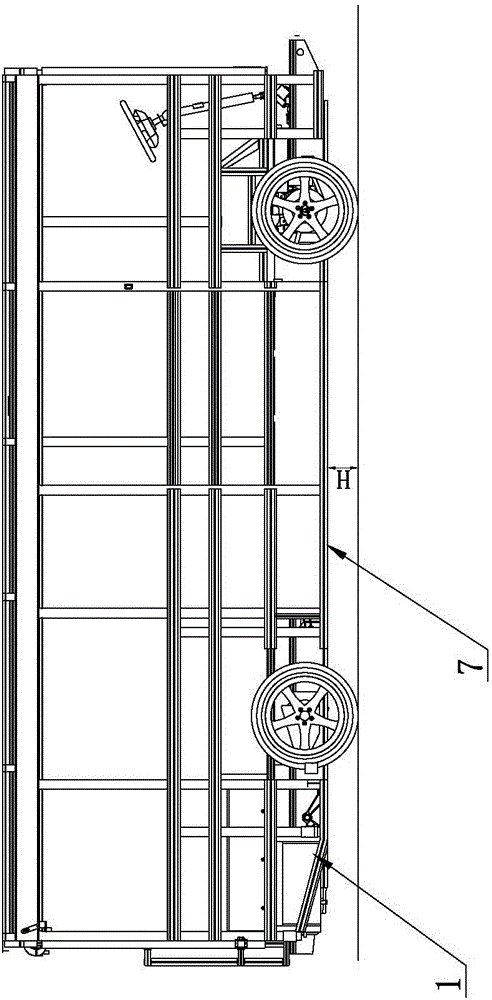

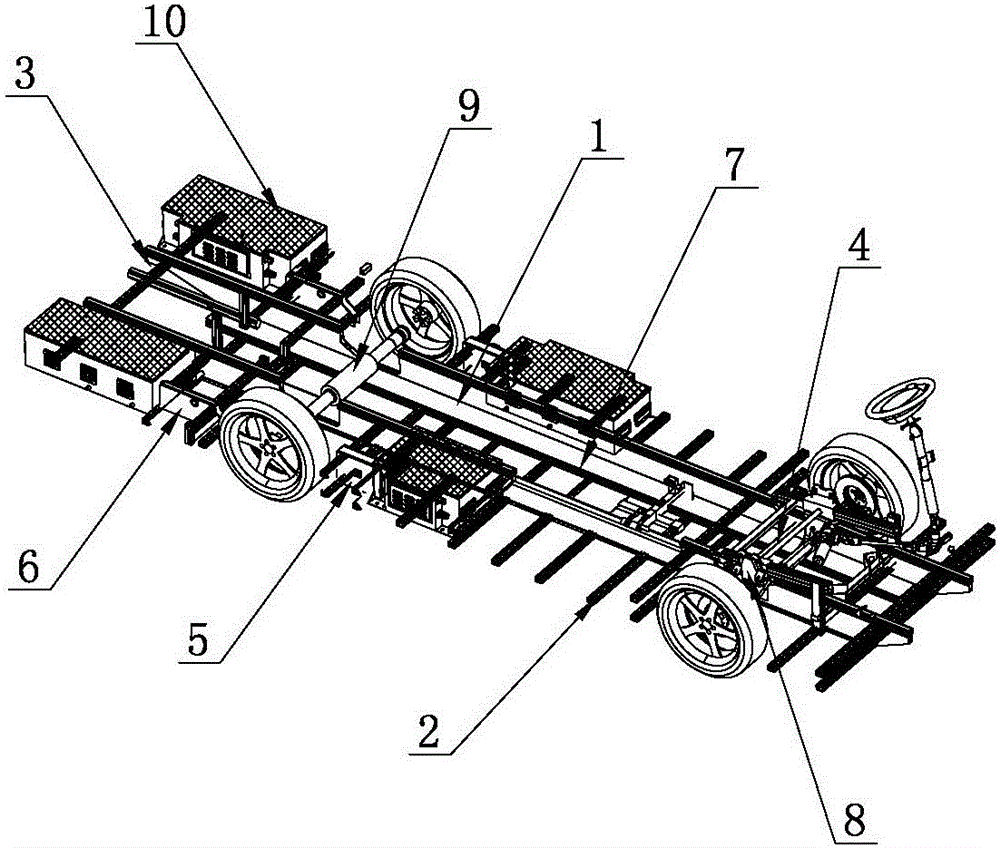

[0041] like Figure 1 to Figure 14 As shown, a light-weight chassis structure of a low-floor electric passenger car of the present invention includes two longitudinal girders 1 and several cross girders 2, and the longitudinal girder 1 includes a horizontal structure area 11 and a vertical structure area 12, and the horizontal structure area 11 is arranged at the bottom of the vertical structure area 12. The structure of the structure area is a cavity structure. Several beams 2 are tenon-jointed to the different longitudinal positions and different height positions of the two longitudinal beams 1 through mortise joint holes to form an integral load-bearing double structure. Longitudinal beam chassis main structure 3, the front part of the double longitudinal beam chassis main structure 3 is connected with front axle saddle 4 through cross beam 2, front axle saddle 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com