Rear earth doped non-fullness tungsten bronze luminescence ferroelectric material and preparation method thereof

A ferroelectric material and rare earth doping technology, which is applied in the field of functional ceramic materials, can solve the problems of unreported luminescence characteristics, achieve excellent luminescence performance, enhance the dielectric constant, and facilitate large-scale industrialization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

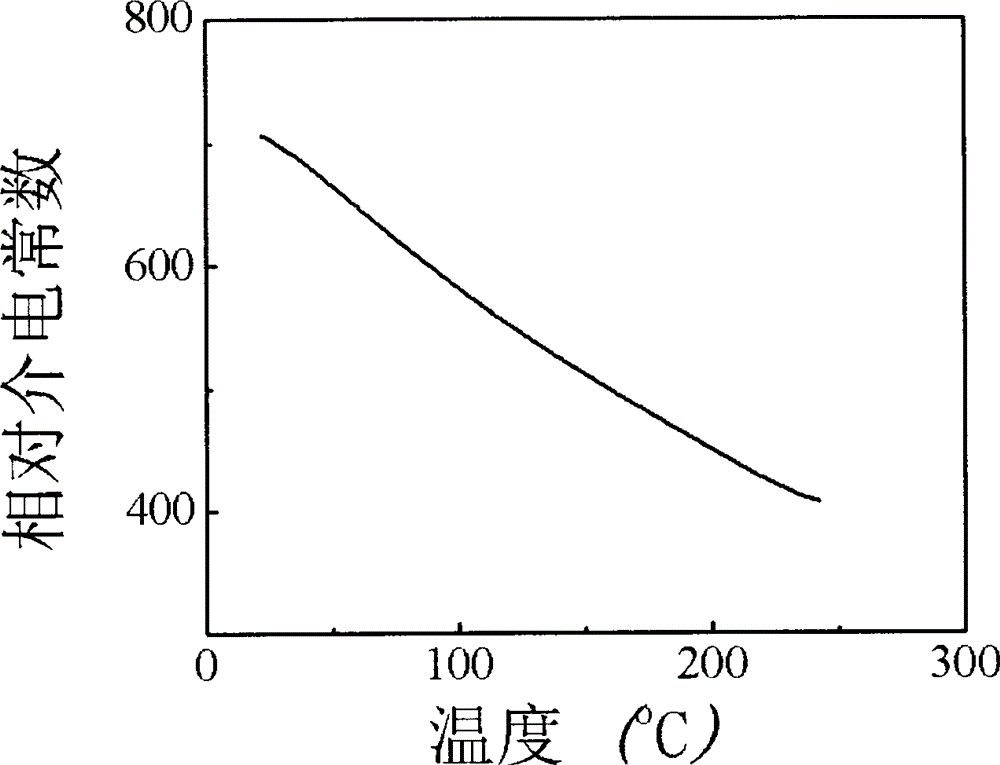

Embodiment 1

[0031] Preparation of Ba 1 La 1-x Eu x TiNb 9 o 30 , where x=0, the preparation method is as follows:

[0032] Analytical grade BaCO 3 (99%), TiO 2 (99%), Nb 2 o 5 (99%), high-purity La 2 o 3 (99.99%) is raw material, carries out proportioning, weighs various raw materials according to molar ratio. Using analytically pure absolute ethanol as the medium, the prepared raw materials were placed in an agate jar, and ball milled on a planetary ball mill for 24 hours. The ball-milled slurry was placed in a beaker, and dried in an oven for 12 hours at a drying temperature of 95 degrees to obtain a dried powder. Grind the dried powder with an agate mortar, then put it in a corundum crucible, put it into a box furnace, heat it up to 1250-1300 degrees for 8-12 hours, and then stop the program after cooling down to 500 degrees, and cool down with the furnace Then ball mill and dry in the same way. The dried powder is granulated, shaped, and finally placed in a corundum boat ...

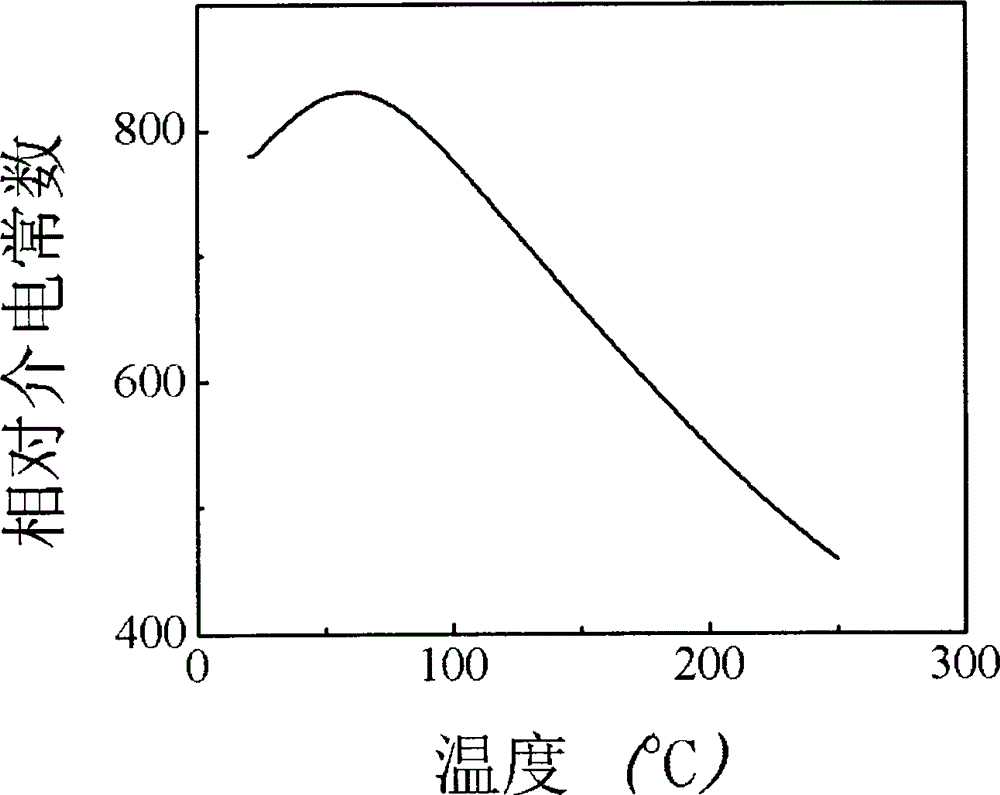

Embodiment 2

[0035] Preparation of Ba 4 La 1-x Eu x TiNb 9 o 30 , wherein x=0.5, the preparation method is as follows:

[0036] Analytical grade BaCO 3 (99%), TiO 2 (99%), Nb 2 o 5 (99%), high-purity La 2 o 3(99.99%), Eu 2 o 3 (99.99%) is raw material, carries out proportioning, weighs various raw materials according to molar ratio. Using analytically pure absolute ethanol as the medium, the prepared raw materials were placed in an agate jar, and ball milled on a planetary ball mill for 24 hours. The ball-milled slurry was placed in a beaker, and dried in an oven for 12 hours at a drying temperature of 95 degrees to obtain a dried powder. Grind the dried powder with an agate mortar, then put it in a corundum crucible, put it into a box furnace, heat it up to 1250-1300 degrees for 8-12 hours, and then stop the program after cooling down to 500 degrees, and cool down with the furnace Then ball mill and dry in the same way. The dried powder is granulated, shaped, and finally pl...

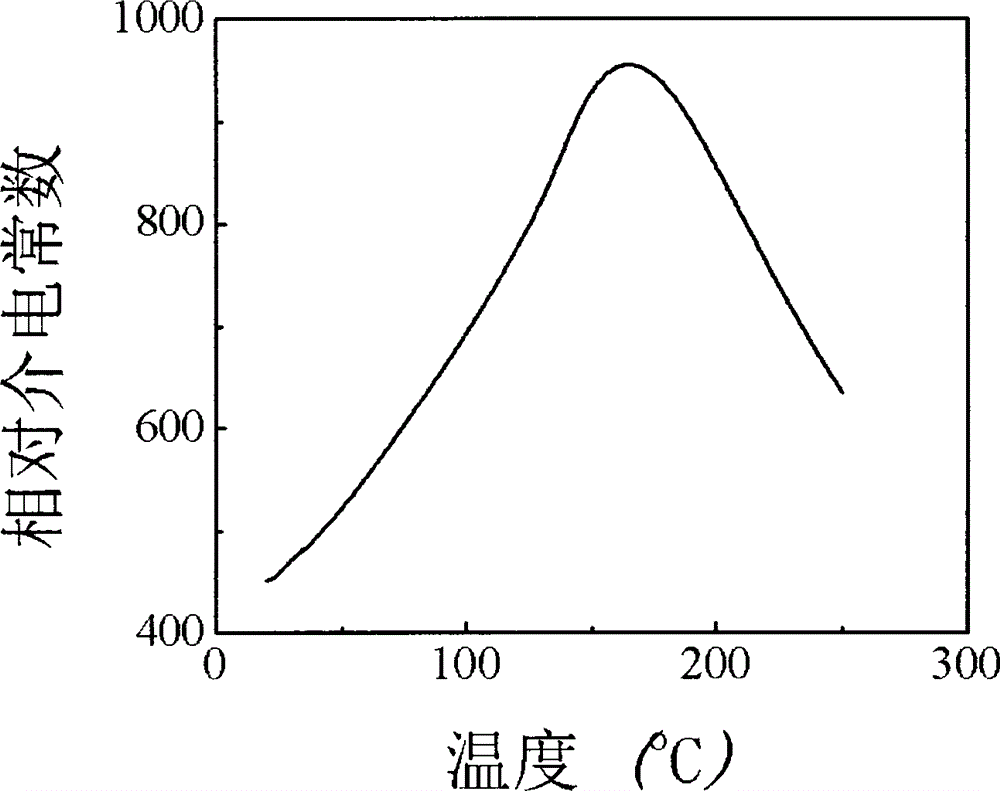

Embodiment 3

[0039] Preparation of Ba 1 La 1-x Eu x TiNb 9 o 30 , where x=1, the preparation method is as follows:

[0040] Analytical grade BaCO 3 (99%), TiO 2 (99%), Nb 2 o 5 (99%), high-purity grade Eu 2 o 3 (99.99%) is raw material, carries out proportioning, weighs various raw materials according to molar ratio. Using analytically pure absolute ethanol as the medium, the prepared raw materials were placed in an agate jar, and ball milled on a planetary ball mill for 24 hours. The ball-milled slurry was placed in a beaker, and dried in an oven for 12 hours at a drying temperature of 95 degrees to obtain a dried powder. Grind the dried powder with an agate mortar, then put it in a corundum crucible, put it into a box furnace, heat it up to 1250-1300 degrees for 8-12 hours, and then stop the program after cooling down to 500 degrees, and cool down with the furnace Then ball mill and dry in the same way. The dried powder is granulated, shaped, and finally placed in a corundum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com