Wear-resistant ceramic material, ceramic local reinforced aluminum matrix composite material and preparation method

An aluminum-based composite material and local reinforcement technology, which is used in the preparation of aluminum-based composite materials and in the field of aluminum-based composite materials, can solve the problems of slow heat dissipation, high density of cast iron, and increased vehicle fuel consumption, so as to improve local wear resistance, The effect of prolonging the service life and reducing the cost of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

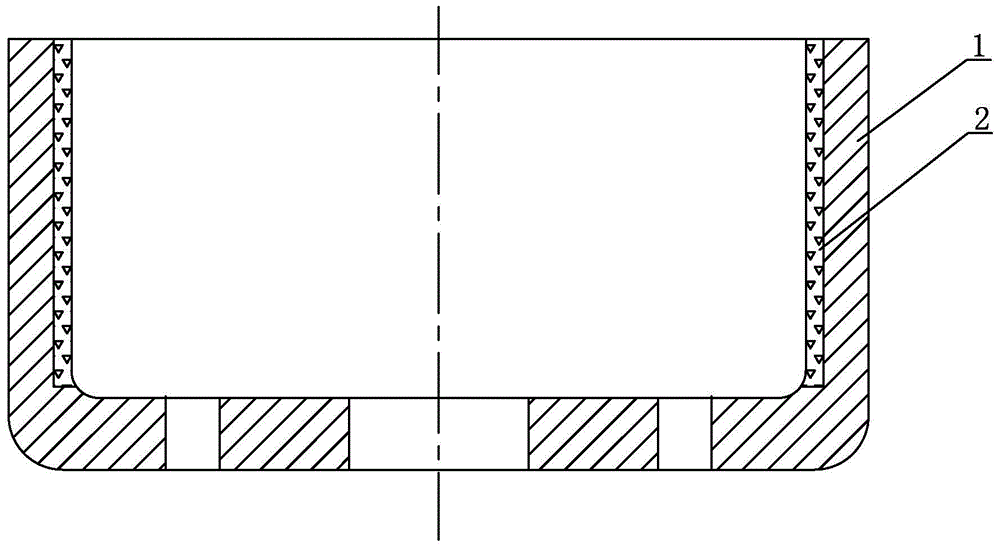

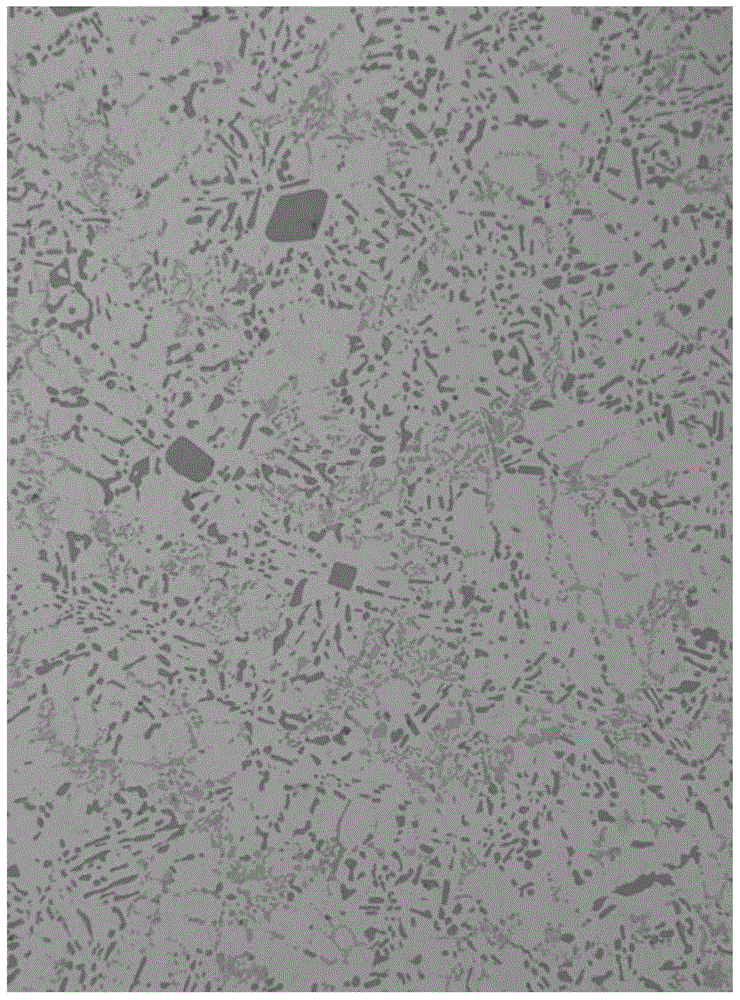

Embodiment 1

[0028] Example 1: Prepare an aluminum alloy brake hub with a wear-resistant layer. The brake hub is made of cast aluminum alloy of the British brand LM24, and its size is Φ480mm (outer diameter) × 227mm (height). Its wear-resistant ceramic material The size of the manufactured wear-resistant layer is Φ420mm (inner diameter)×180mm (height)×7mm (thickness). The preparation method comprises the following steps: by volume fraction, 12% of aluminum silicate short fibers, 8% of silicon carbide particles and 20% of carboxymethyl cellulose aqueous solution with a concentration of 5% and 60% of a concentration of 10% After the silica sol solution is evenly mixed, it is quantitatively poured into the prefabricated part mold and vacuumized to 1×10 -2 Pa, pressurize 20 ~ 30MPa, dewater and press into a ring-shaped prefabricated part, the size of the prefabricated part is Φ420mm (inner diameter) × 180mm (height) × 7mm (thickness); Drying at ℃ for 15 hours, and then sintering at 700-1000℃ ...

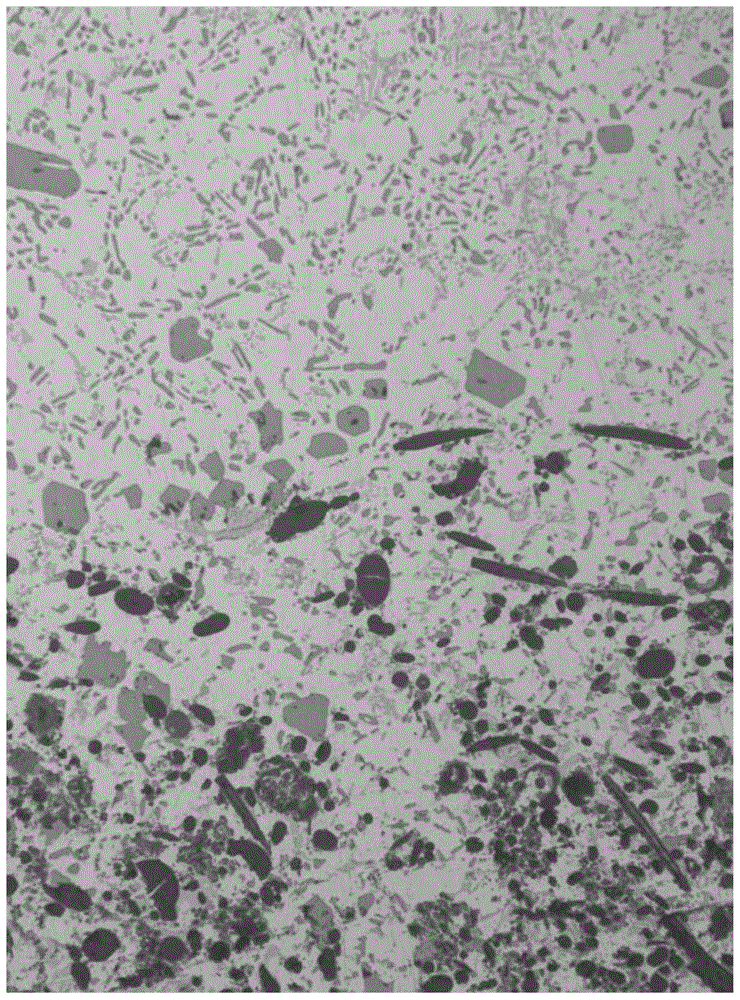

Embodiment 2

[0029] Example 2: Prepare an aluminum alloy brake disc with a wear-resistant layer. The brake disc is made of cast aluminum alloy of the American brand A356, and its size is Φ288mm (outer diameter) × 44.3mm (thickness), and its wear-resistant ceramic The size of the wear-resistant layer made of material is Φ288mm (outer diameter)×184mm (inner diameter)×3mm (thickness). The preparation method comprises the following steps: by volume fraction, 8% alumina short fibers, 7% aluminum silicate short fibers, 5% fly ash particles, 5% silicon carbide particles and 25% concentration of 3 % carboxymethyl cellulose aqueous solution and 50% silica sol solution with a concentration of 12% are uniformly mixed, quantitatively poured into the preform mold, and vacuumed to 1×10 -2 Pa, pressurize 20 ~ 30MPa, dewater and press into a ring-shaped prefabricated part, the size of the prefabricated part is Φ288mm (outer diameter) × 184mm (inner diameter) × 3mm (thickness); Drying at 200°C for 10 hour...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com