Streptomyces lutetsis lt-2 producing keratinase and its application method

A technology of keratinase and application method, which is applied in the field of microorganisms and achieves the effects of mild degradation conditions, broad application prospects and simple operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

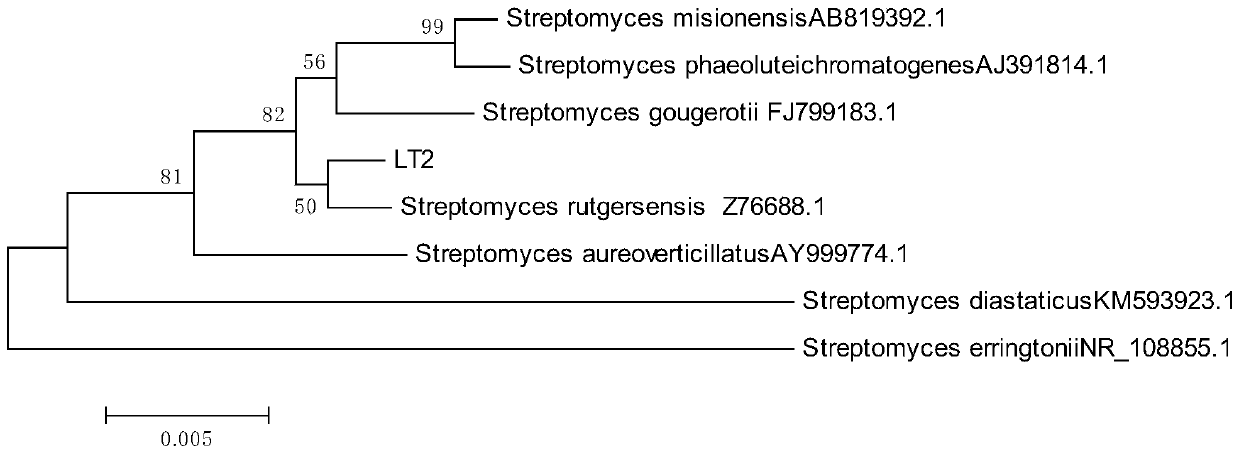

[0021] Example 1 Screening and identification of keratinase-producing strains

[0022] 1. Culture medium formula

[0023] (1) Preliminary screening of solid medium: every 1000 ml contains 10-15 grams of pig hair powder, K 2 HPO 4 1.0~1.4g, KH 2 PO 4 0.5~1.0g, NaCl 0.1~0.5g, MgSO 4 0.05 to 0.1 grams, 15 to 20 grams of agar, and water as the balance. pH7.5~8.0.

[0024] The production of pig hair powder on the screening medium: remove the pig skin, wash the pig hair, dry to constant weight, then cut the pig hair to about 1cm with scissors, then crush it with a pulverizer, and pass through a 100-mesh sieve.

[0025] (2) Preservation medium on slant

[0026] Gao's medium: every 1000 ml contains 15-20 grams of soluble starch, KNO 3 0.8~1.2g, NaCl0.5~1.0g, K 2 HPO 4 0.5~1.0g, MgSO 4 0.5~1.0g, FeSO 4 ·7H 2 O 0.005-0.01 grams. pH7.2-7.5, 15-20 grams of agar, and water as the balance.

[0027] LB solid medium: 8-12 grams of protein per 1000 ml, 3-7 grams of yeast po...

Embodiment 2

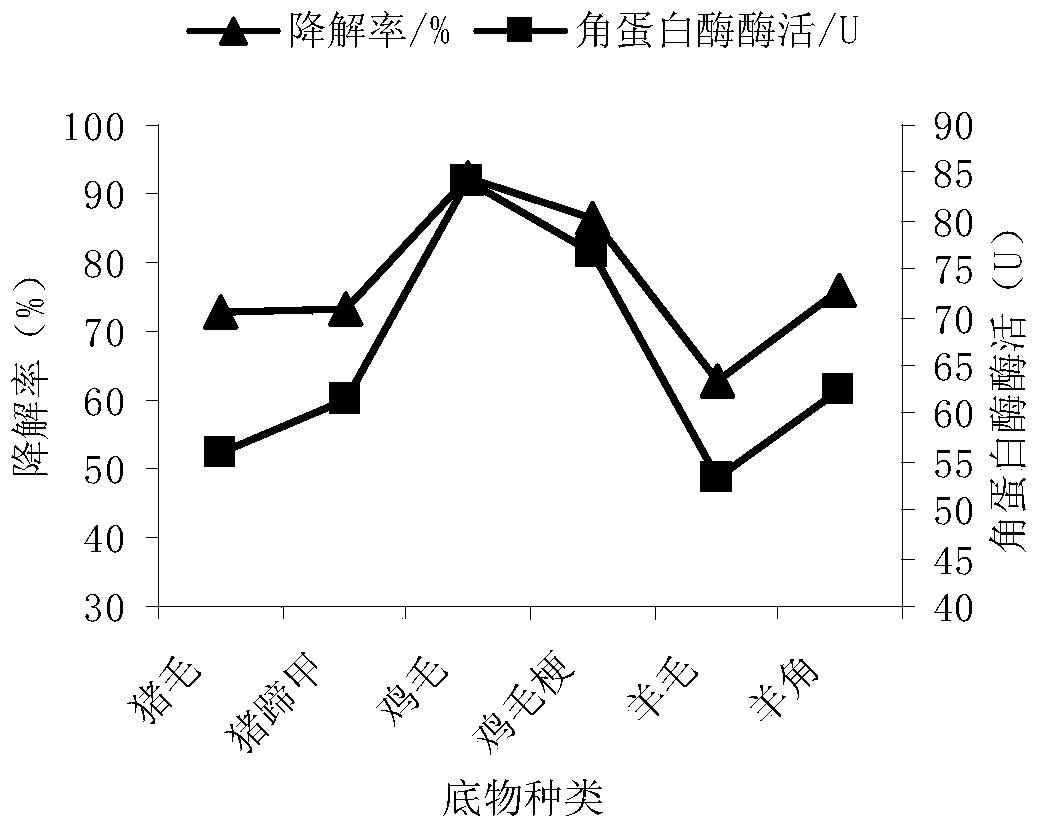

[0047] Degradation effect determination of embodiment 2 bacterial strain

[0048] 1. Determination of keratinase activity

[0049] Add 5 mg of pig hair powder to 1 ml of 50 mmol / L Tris buffer (pH8.0) to suspend; add 1 ml of crude enzyme solution diluted 10 times with the same Tris buffer; add 2 ml of TCA ( 0.4mol / L) stop solution; react at 50°C, 150rpm warm bath for 45min; add 2ml of TCA (0.4mol / L) to stop the reaction; centrifuge at 6000rpm for 10min; OD value.

[0050] Definition of enzyme activity unit: Under specific reaction conditions, the amount of enzyme produced by decomposing keratin per milliliter increases the OD value by 0.01, which is regarded as 1 U of keratinase activity unit.

[0051] Enzyme reaction substrate pig hair powder production: the method is the same as that of the screening medium pig hair powder, except that the pig hair powder that has been crushed and passed through a 100-mesh sieve is then ground with liquid nitrogen to make it finer and finer...

Embodiment 3

[0056] The expanded culture method of embodiment 3 bacterial strain LT-2

[0057] 3. The expansion culture method of bacterial strain LT-2 is

[0058] Strain LT-2 was inoculated on the slant of solid seed medium, activated and cultured at 30-35°C for 2-3 days, and a large number of spores were formed on the slant.

[0059] Scrape the spores from the activated slope, use sterile water to make a uniform spore suspension, then inoculate the spore suspension into the spore-forming medium, and culture it on a shaking table at 30-35 ° C for 3-5 days at 200 rpm. The bottle culture solution is the seed solution.

[0060] Fermentation tank culture: The amount of medium in the fermenter is 50-70% of the total volume, the inoculum volume accounts for 1-3% of the medium volume, the fermentation temperature is 30-35°C, sterile air is introduced, and the culture is stirred at 180-200rpm , the ratio of the ventilation volume to the volume of the fermentation broth is 0.9:1-1:1, the tank pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com