Titanium alloy for damping bicycle frame and preparation method thereof

A titanium alloy and bicycle technology, applied in the field of titanium alloy, can solve the problems of easy rust, easy breakage, and limited load-bearing capacity of the frame, and achieve the effects of strong fatigue resistance, non-deformation, and strong load-bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

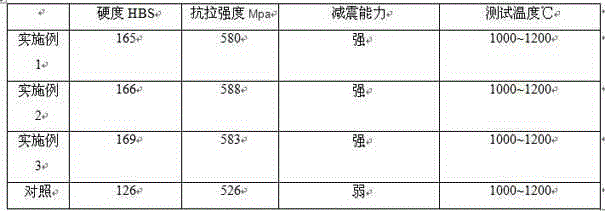

Embodiment 1

[0018] A titanium alloy for a shock-absorbing bicycle frame. The main elements of the titanium alloy are: 0.6% cobalt element, 0.5% nickel element, 1% iron element, 0.5% silicon element, 0.3% molybdenum element, and aluminum element 0.2%, the balance is titanium and unavoidable impurities. Impurities include phosphorus, sulfur, and selenium. Phosphorus 0.1%, sulfur 0.1%, selenium 0.1%.

[0019] The preparation method of the titanium alloy that can absorb shock bicycle frame, comprises the following steps:

[0020] 1) Weigh titanium alloy, silicon-aluminum alloy and cobalt-nickel alloy as raw materials according to weight percentage respectively, add them to the melting furnace and heat at 800°C to melt all the materials in the melting furnace. The melting time is 10 hours, and add phosphorus removal agent and desulfurization agent Remove sulfur and phosphorus elements;

[0021] 2) Pass N into the melting furnace 2 -Cl 2 Mixed gas, refined at a temperature of 700°C for 10...

Embodiment 2

[0028] A titanium alloy for a shock-absorbing bicycle frame. The main elements of the titanium alloy are: 3.0% cobalt element, 2.0% nickel element, 2% iron element, 0.7% silicon element, 0.4% molybdenum element, and aluminum element 0.3%, the balance is titanium and unavoidable impurities. Impurities include phosphorus, sulfur, and selenium. Phosphorus 0.05%, sulfur 0.06%, selenium 0.03%.

[0029] The preparation method of the titanium alloy that can absorb shock bicycle frame, comprises the following steps:

[0030] 1) Weigh titanium alloy, silicon-aluminum alloy and cobalt-nickel alloy as raw materials according to weight percentage, add them to the melting furnace and heat at 830°C to melt all the materials in the melting furnace. The melting time is 8 hours, and add phosphorus removal agent and desulfurization agent at the same time Remove sulfur and phosphorus elements;

[0031] 2) Pass N into the melting furnace 2 -Cl 2 Mixed gas, refined at a temperature of 750°C ...

Embodiment 3

[0038] A titanium alloy for a shock-absorbing bicycle frame, the main elements of the titanium alloy are composed of: the main elements of the titanium alloy are: 1.8% of cobalt element, 1.25% of nickel element, 1.5% of iron element, 0.6% of silicon element, Molybdenum element 0.35%, aluminum element 0.25%, the balance is titanium and unavoidable impurities. Impurities include phosphorus, sulfur, and selenium. Phosphorus 0.02%, sulfur 0.03%, selenium 0.05%.

[0039] The preparation method of the titanium alloy that can absorb shock bicycle frame, comprises the following steps:

[0040] 1) Weigh titanium alloy, silicon-aluminum alloy and cobalt-nickel alloy as raw materials according to weight percentage respectively, add them to the melting furnace and heat at 815°C to melt all the materials in the melting furnace. The melting time is 9 hours, and add phosphorus removal agent and desulfurization agent at the same time Remove sulfur and phosphorus elements;

[0041] 2) Pass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com