Single fiber bundle probe differential pressure sensor

A differential pressure sensor and optical fiber probe technology, applied in the sensor field, can solve problems such as poor practicability, unsuitable differential pressure sensor, and inability to meet differential pressure measurement requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

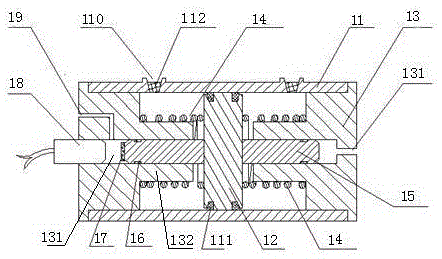

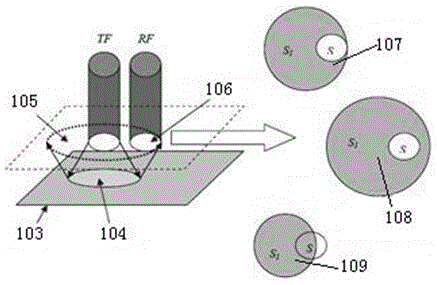

[0069] refer to figure 1 , the present embodiment provides a single fiber bundle probe differential pressure sensor, including a sensor probe 1, a photodetector 2, a signal processor 3, a light source 4, a Y-coupler 5 and an optical fiber 6;

[0070] The sensor probe 1 includes a housing 11, the housing 11 is a cylindrical structure, a piston 12 is slidingly arranged in the housing 11, the material of the piston 12 is hard aluminum alloy, and a piston seal is arranged between the piston 12 and the inner wall of the housing 11 Ring 111, a spring 14 is respectively arranged at the two ends of the piston 12, and the structure and specifications of the two springs 14 are all the same. One end of the spring 14 is all fixed on the piston 12, and the two ends of the housing 11 are respectively sealed and fixed with an end cover 13, and the middle part of the end cover 13 is provided with a raised portion 132 extending into the housing 11, and the raised portion 132 is in contact wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com