Surface-coated solid solution cathode material and preparation method thereof

A positive electrode material and surface coating technology, which is applied in the field of lithium-ion battery solid solution positive electrode materials and its preparation, can solve the problems of poor rate performance, low first Coulombic efficiency, poor rate performance improvement, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

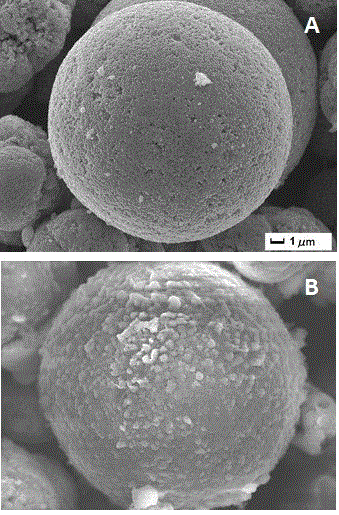

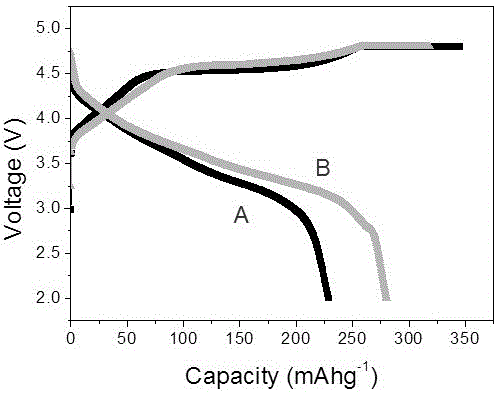

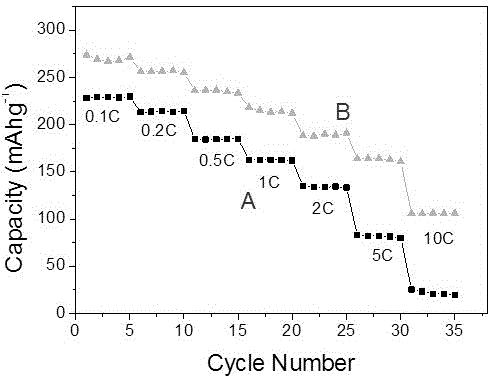

[0019] Example 1: Weigh nickel sulfate, cobalt sulfate, manganese sulfate and NaOH according to the stoichiometric ratio, and prepare a 0.1mol / L solution, and control the temperature of the aqueous solution at 50°C and the pH value at 7.0 by ultrasonic external field assisted coprecipitation method , to prepare the precursor; then mixed with lithium carbonate weighed according to the stoichiometric ratio, mechanically activated for 1h, calcined at 400°C for 1h, then calcined at 750°C for 8h, and finally cooled to obtain a lithium-rich solid solution positive electrode material 0.5Li 2 MnO 3 0.5LiNi 0.3 co 0.4 mn 0.3 o 2 ; Then follow Li 0.5 Ni 0.5 mn 1.5 o 4 The stoichiometric ratio of lithium acetate, manganese acetate and nickel acetate was weighed, oxalic acid was selected as the organic chelating agent, they were dissolved in an aqueous solution, and stirred into a sol at 50 ° C, and an appropriate proportion of lithium-rich solid solution positive electrode materia...

Embodiment 2

[0020] Example 2: Weigh nickel nitrate, cobalt nitrate, manganese nitrate and NaOH according to the stoichiometric ratio, and prepare a 0.5mol / L solution, and control the temperature of the aqueous solution at 60°C and the pH value at 9.0 by ultrasonic external field assisted coprecipitation method , to prepare the precursor; then mixed with lithium carbonate weighed according to the stoichiometric ratio, mechanically activated for 12 hours, calcined at 450°C for 12h, then calcined at 850°C for 24h, and finally cooled to obtain a lithium-rich solid solution positive electrode material 0.5Li 2 MnO 3 0.5LiNi 0.5 mn 0.5 o 2 ; Then follow Li 0.35 Cr 0.5 mn 1.5 o 4 The stoichiometric ratio of lithium acetate, manganese acetate and chromium acetate was weighed, oxalic acid was selected as the organic chelating agent, they were dissolved in aqueous solution, and stirred into a sol at 60 ° C, and an appropriate proportion of lithium-rich solid solution positive electrode materia...

Embodiment 3

[0021] Embodiment 3: Weigh nickel sulfate, cobalt sulfate, manganese sulfate and NaOH according to the stoichiometric ratio, and prepare a 1mol / L solution, and control the temperature of the aqueous solution at 80°C and the pH value at 11.0 by ultrasonic external field assisted coprecipitation method, Prepare the precursor; then mix it with lithium carbonate weighed according to the stoichiometric ratio, mechanically activate it for 6 hours, bake it at 400°C for 6 hours, then bake it at 900°C for 12 hours, and finally cool it to obtain a lithium-rich solid solution positive electrode material 0.5Li 2 MnO 3 0.5LiNi 0.4 co 0.4 mn 0.2 o 2 ; Then follow Li 0.7 Ti 0.5 mn 1.5 o 4 The stoichiometric ratio of lithium acetate, manganese acetate and Ti(C 4 h 9 O) 4 , choose ethylene glycol as the organic chelating agent, dissolve them in the aqueous solution, and stir them into a sol at 70 ° C, and put an appropriate proportion of lithium-rich solid solution positive electrode...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com