Preparation method of carbon material for cathode of lead-acid storage battery

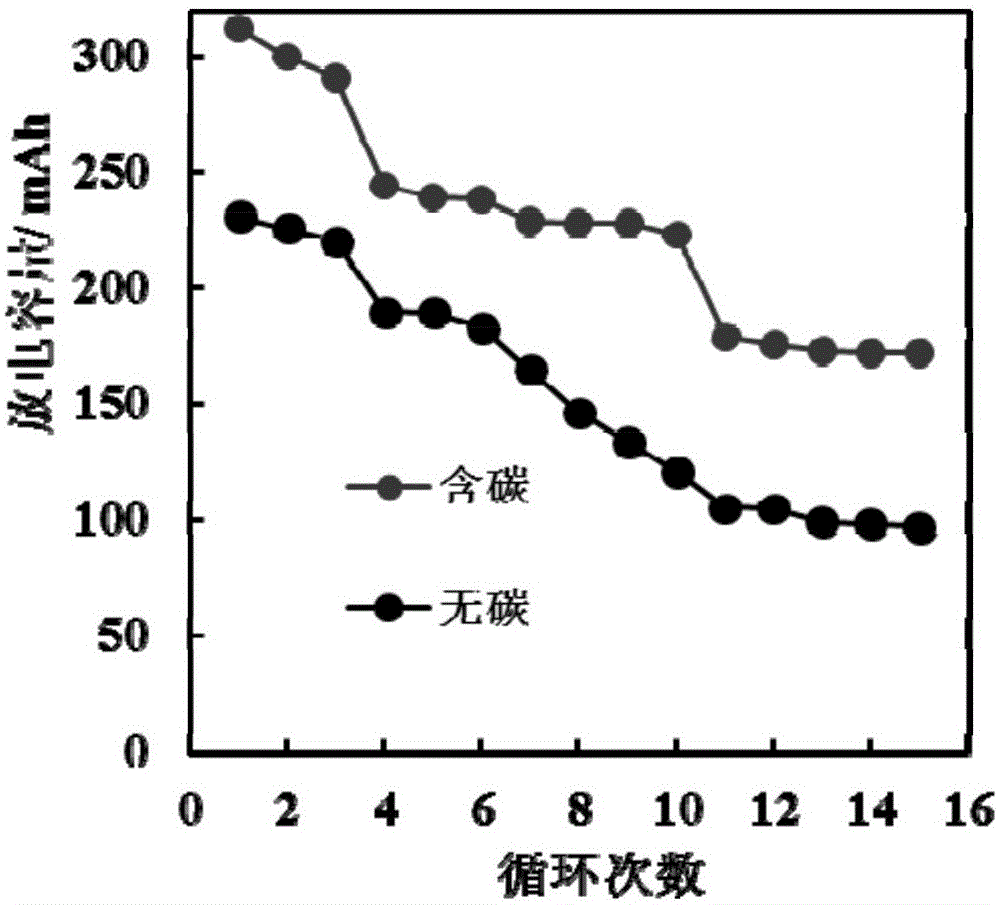

A lead-acid battery, carbon material technology, applied in lead-acid batteries, battery electrodes, chemical instruments and methods, etc., can solve problems such as sulfation and limit battery cycle life, and achieve the effect of improving bonding and prolonging cycle life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

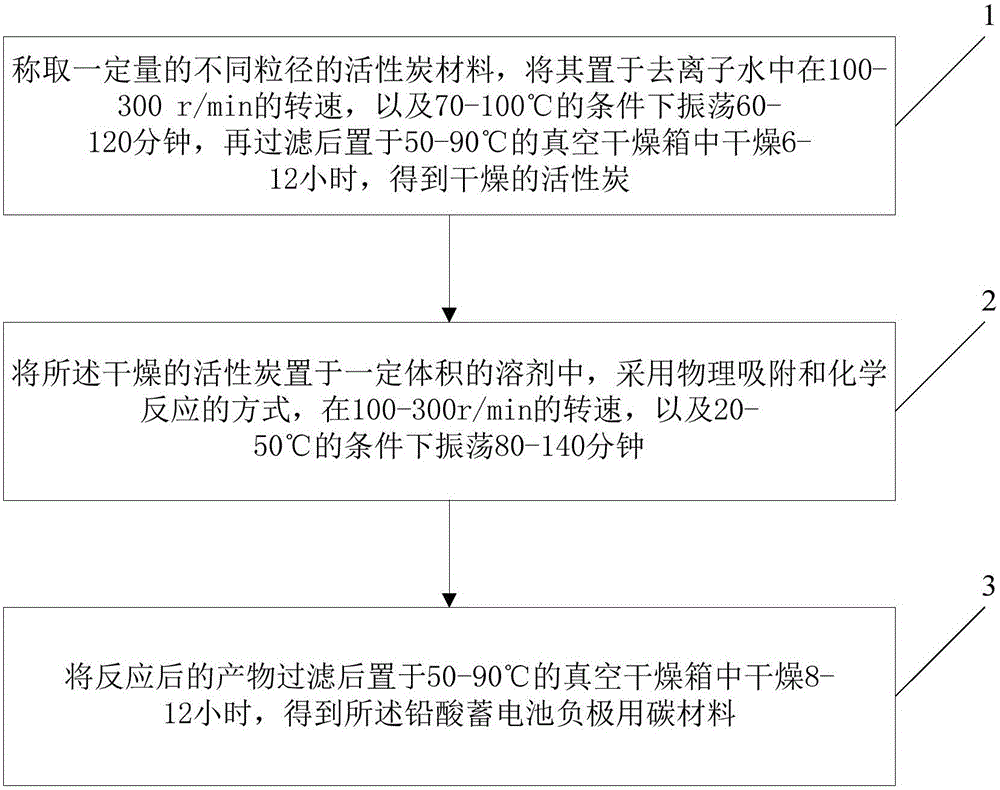

Method used

Image

Examples

Embodiment 1

[0026] Example 1. Weigh 10g of activated carbon with a particle size of 2-4μm in a 300mL Erlenmeyer flask, add 200mL of deionized water, shake at 80°C for 120min, then filter while hot, and dry in a vacuum oven at 80°C 10 hours.

[0027] Weigh 2 g of activated carbon, add it into the lead nitrate solution, shake for 90 minutes at pH = 4.0, room temperature, and rotational speed 200 r / min.

[0028] The obtained lead-carbon composite material was filtered and dried in a vacuum oven at 80° C. for 8 hours.

[0029] The proportion of lead in the obtained lead-carbon composite material is 5% by weight. Electronic scanning of the prepared carbon material shows that lead particles grow out of the gaps of the activated carbon particles or cover the surface of the activated carbon. The specific capacitance of this carbon material was 93.7 F / g.

[0030] Embodiment 2-4, three kinds of activated carbon materials with the particle diameters of the activated carbon weighed in 1-2 μm and 4-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific capacitance | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap