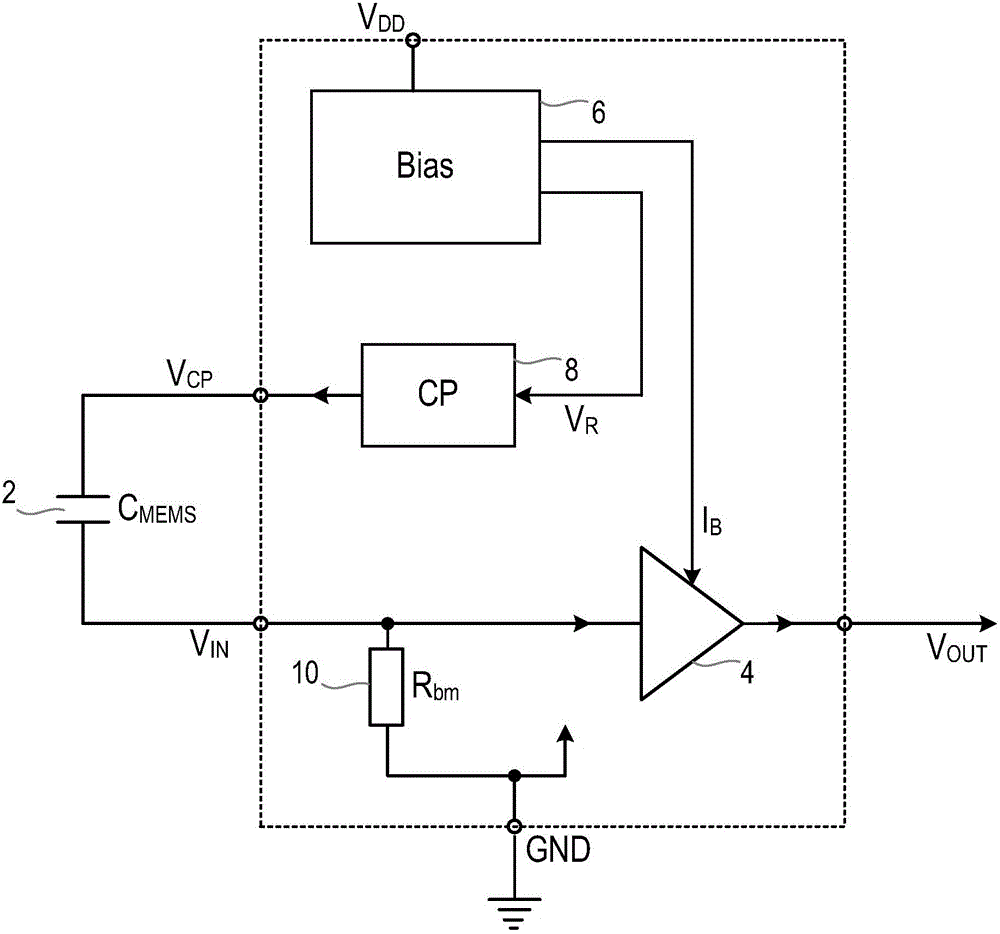

Low noise amplifier for MEMS capacitive transducers

A transducer and amplifier circuit technology, applied in low-noise amplifiers, electrostatic transducer microphones, low-frequency amplifiers, etc., can solve the problems of high power consumption, output signal distortion, low power, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

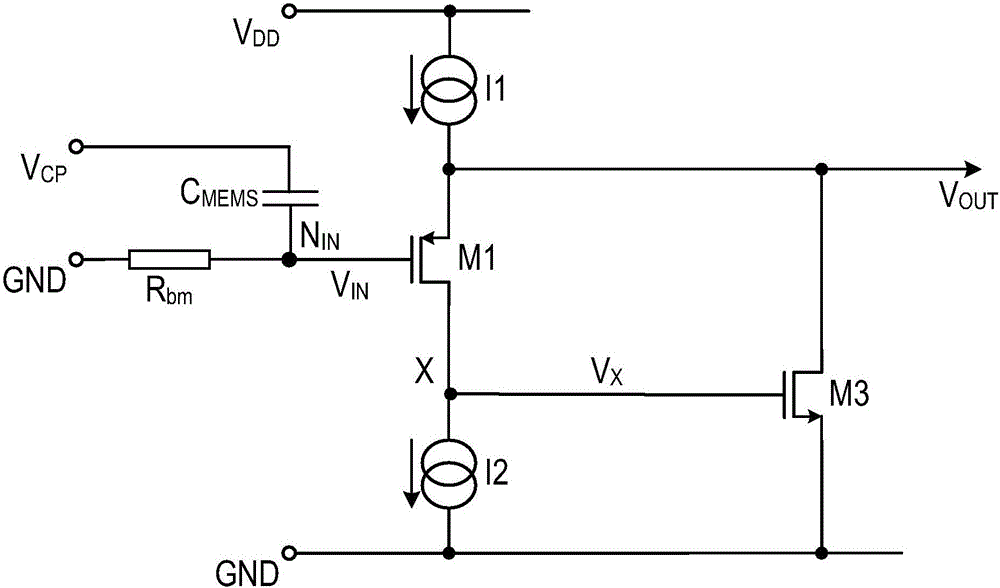

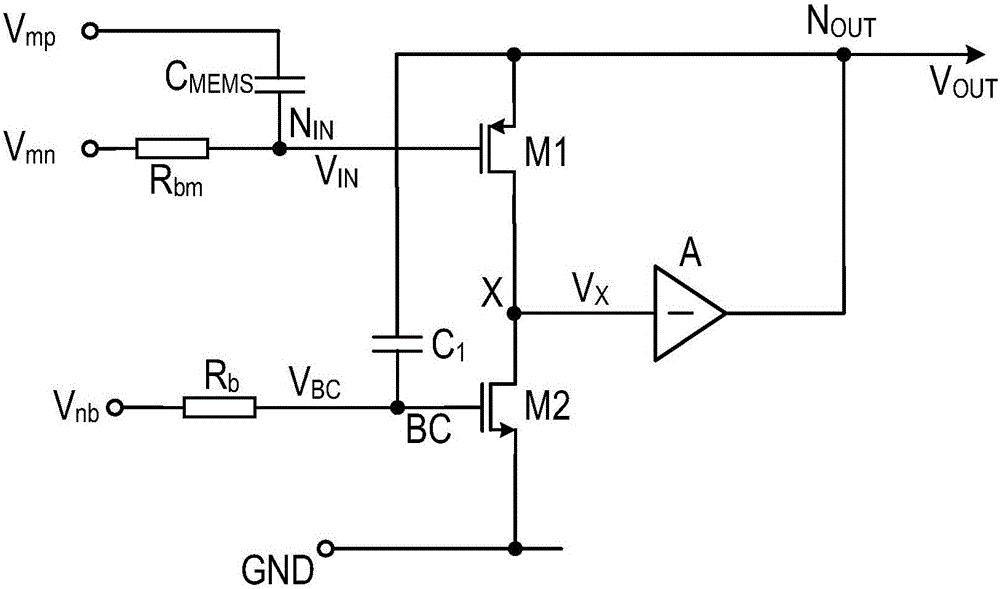

[0075] The present invention provides a preamplifier circuit that uses a super source follower to maintain low output impedance and stable signal gain.

[0076] As discussed above, in some applications a relatively simple amplifier may be more suitable than a conventional long-tailed pair input stage. However, conventional source follower arrangements can suffer from load-dependent gain and distortion of large output signals. The use of a class A super source follower can provide a smaller output impedance than a conventional source follower, while requiring a smaller supply current. figure 2 An amplifier is shown that includes a super source follower arrangement. This implementation of the MEMS transducer amplifier includes a Class A super source follower. There are two MOS transistors M1 and M3, in this embodiment M1 is a PMOS transistor and M3 is an NMOS transistor. There are also constant current sources I1 and I2 connected as shown. These can also be implemented usin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com