Polishing device capable of controlling horizontal contact pressure

A technology of polishing device and contact pressure, which is applied in the direction of grinding/polishing equipment, optical surface grinder, grinding machine tool parts, etc. It can solve the problems affecting the local modification ability and surface accuracy of polishing tools, and realize the distribution of removal amount , Improve stability, improve the effect of surface shape accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

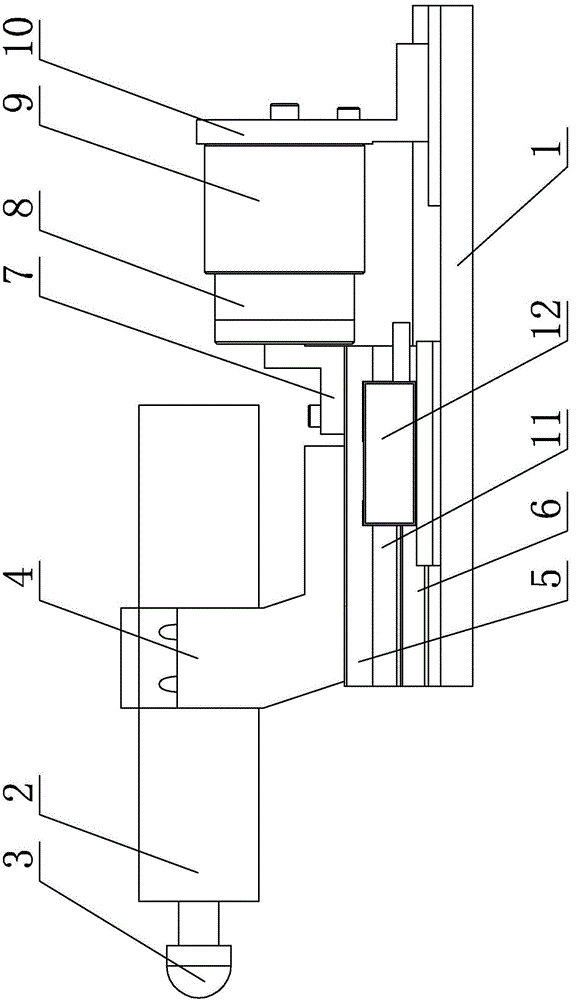

[0013] Specific implementation mode one: as figure 1 As shown, the polishing device with controllable horizontal contact pressure in this embodiment includes a polishing device base 1, a polishing spindle 2, a polishing head 3, a spindle mounting seat 4, a linear slide slide 5, a linear slide base 6, Voice coil motor coil connector 7, voice coil motor coil 8, voice coil motor magnet 9 and motor magnet steel connector 10, the polishing device also includes a grating 11 and a position reading display device 12, and the polishing device base 1 is horizontally arranged , the linear sliding table base 6 and the motor magnetic steel connector 10 are installed on the upper end surface of the polishing device base 1 sequentially along the length direction of the polishing device base 1, and the linear sliding table slide plate 5 is along the length of the linear sliding table base 6. The length direction is slidingly installed on the upper end surface of the linear slide base 6, the s...

specific Embodiment approach 2

[0014] Specific implementation mode two: as figure 1 As shown, the polishing head 3 of this embodiment is a polyurethane elastomer hemispherical polishing head. With such a design, the contact area can be adjusted according to the radius of the spherical surface, and the controllable contact pressure between the polishing tool and the workpiece can be controlled. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0015] Specific implementation mode three: as figure 1 As shown, the coil connector 7 of the voice coil motor in this embodiment is an "L"-shaped connector. With such a design, when ensuring that the voice coil motor coil 8 and the linear slide 5 move in the same direction, it is convenient to adjust the relative height position of the two and improve the flexibility of parts arrangement. Other compositions and connections are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com