Immersed flat sheet membrane bioreactor with micro-channel turbulence-flow promoters

A membrane bioreactor, technology of biological reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

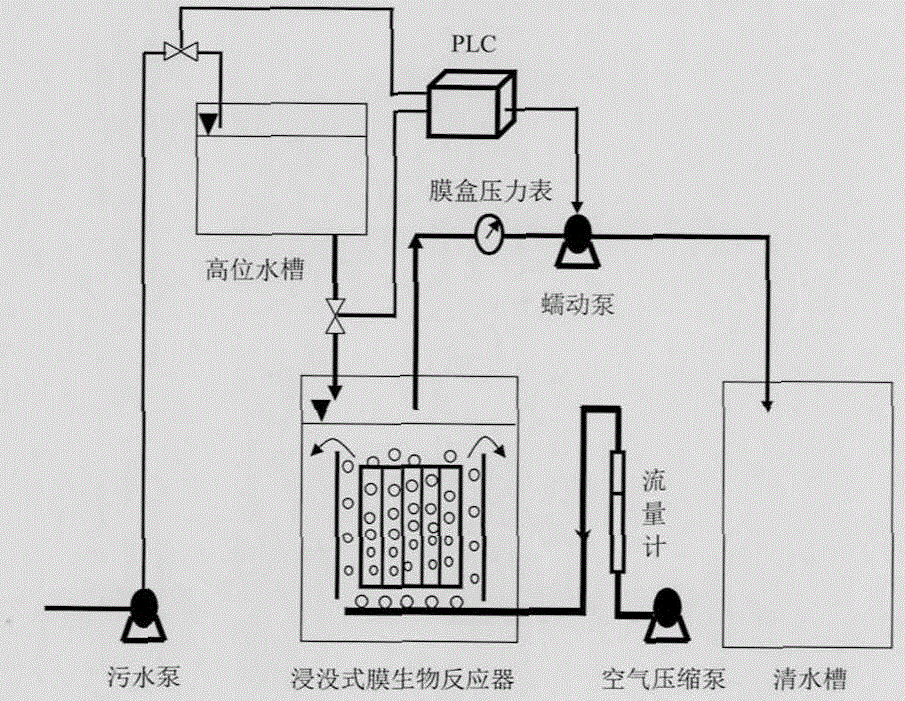

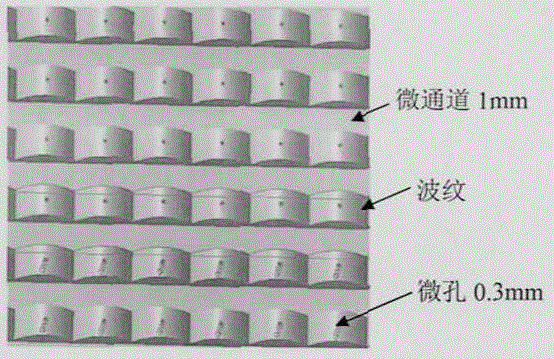

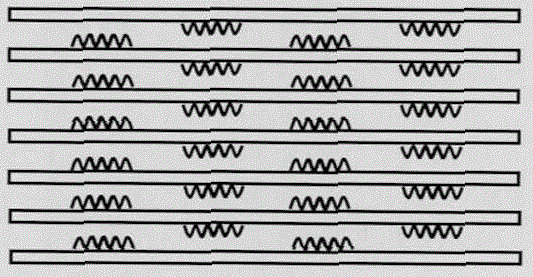

[0013] see figure 1 , a submerged flat-panel membrane bioreactor with additional microchannel turbulence promoters, including a bioreactor, a flat membrane module and a microchannel turbulence promoter arranged in the bioreactor, the microchannel turbulence promoters are placed crosswise on the flat membrane On the surface, the aerator is arranged under the flat membrane module and the microchannel turbulence promoter. The aerator adopts an aeration tube with a plurality of small holes. At the same time, it drives the sewage to rise and flow in the gap formed by the flat membrane module and the microchannel turbulence promoter. At this time, the air bubbles are in the throttling flow state, and the cross flow required for cleaning the membrane surface is generated by air agitation. The gas device is set directly below the membrane, and the mixed liquid flows upward with the air flow, generating cross-flow shear force on the membrane surface, which can reduce membrane fouling, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com