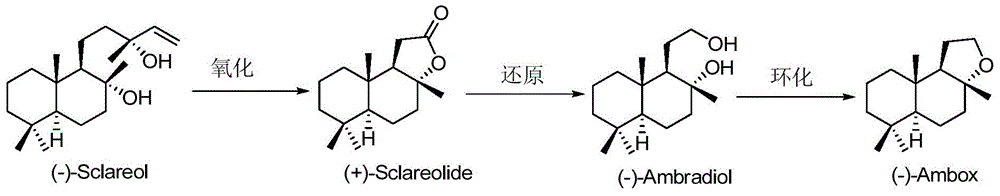

Preparation method for ambrox

A technology of ambroxan and ambroxol, which is applied in the field of daily chemicals, can solve the problems of harsh reaction conditions, large pollution, and expensive catalysts, and achieve the effects of being suitable for industrial production, less environmental pollution, and convenient post-treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

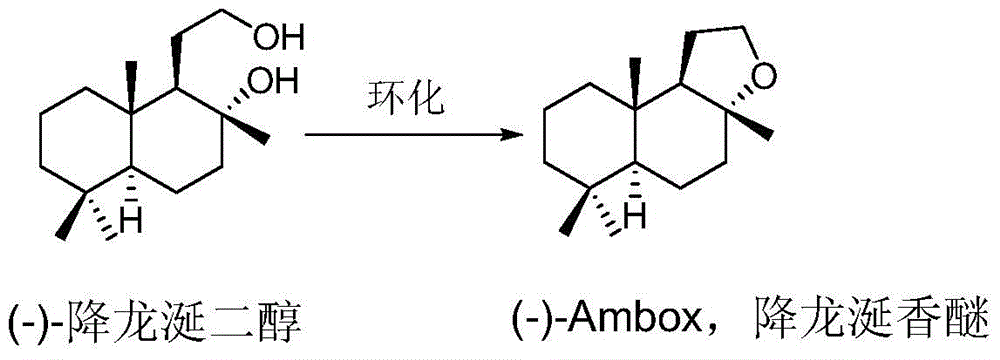

[0025] Such as figure 2 As shown, a method for preparing ambrox, in which ambroxol and activated molecular sieves are uniformly stirred and reacted in an organic solvent according to a mass ratio of 1:1 to 1:20 to obtain a reactant, and heated to reflux during the reaction 12~36 hours, obtain reactant after reaction, filter reactant after reaction, add water or organic solvent (preferably organic solvent) to filter when filtering, and reclaim molecular sieve from reactant, and filtrate (this filtrate is The solution formed by the remaining material after the molecular sieve is recovered from the reactant) is distilled and the organic solvent in the filtrate is recovered. After the filtrate is distilled, the crude product Ambroxan is obtained, and the crude product Ambroxan is obtained through recrystallization treatment. Quality Ambroxan.

[0026] The preferred mass ratio technical scheme of activated molecular sieve and organic solvent in the present invention is as follows...

Embodiment 1

[0037]Put 10g of ambroxol and 100g of 3A molecular sieve (activated at 300°C for 2 hours before use) in a 250mL three-necked flask, then add 100mL of toluene, stir evenly, heat and reflux for 20 hours, the heating temperature is 100°C, filter the reactant Molecular sieves were recovered, and the filtrate was distilled under reduced pressure to recover toluene to obtain crude ambroxan, which was dissolved in petroleum ether for recrystallization to obtain 7.71 g of white crystals. Thus the final yield of Ambrox was 83.0%.

Embodiment 2

[0039] Put 10g of Ambroxol and 100g of 4A molecular sieve (activated at 300°C for 2 hours before use) into a 250mL three-necked flask, then add 100mL of toluene, stir evenly, and heat to reflux for 20 hours at a temperature of 120°C. The reactants after the reaction were filtered to recover molecular sieves, and the filtrate was distilled under reduced pressure to recover toluene, and the crude ambrox was recrystallized with dichloromethane to obtain the target product, so that the final yield of ambrox was 78.0%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com