A method for continuously separating biogas by pressure swing adsorption

A pressure swing adsorption and biogas technology, applied in separation methods, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of increasing costs and increasing production costs, and achieve the effects of energy saving, convenient operation and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

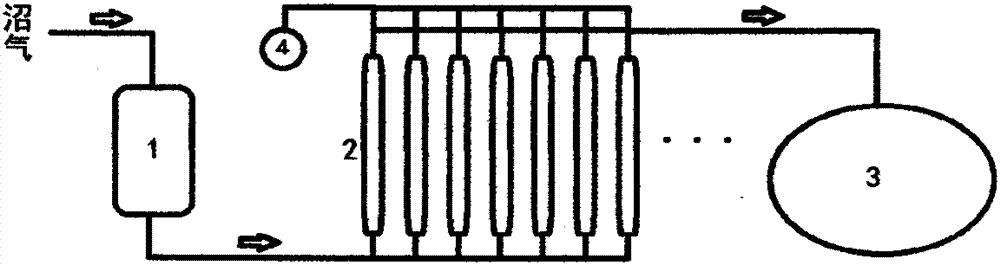

Image

Examples

Embodiment 1

[0024] The dehydrated and desulfurized biogas is passed into the buffer tank for temporary storage. At this time, the content of methane in the biogas is about 60%, and the content of carbon dioxide is about 40%. Biogas according to 1500h -1 The volume space velocity is passed into an adsorption tower bed layer, and the pressure of the passage is kept at 0.1MPa. Under the selective adsorption of the adsorption material, the carbon dioxide in the biogas is adsorbed by the adsorbent, while the unadsorbed methane will be discharged through the outlet and enter the gas storage bag. When CO is detected at the outlet of the adsorption tower 2 When the content is greater than 2%, it means that the adsorption tower will absorb CO 2 At this time, through program control, the biogas will be passed to the next adsorption tower for adsorption and separation, and the CO will be adsorbed 2 The saturated adsorption tower performs vacuum degassing operation, and the valve can be adjusted t...

Embodiment 2

[0026] The dehydrated and desulfurized biogas is passed into the buffer tank for temporary storage. At this time, the content of methane in the biogas is about 60%, and the content of carbon dioxide is about 40%. Biogas according to 1500h -1 The volume space velocity is passed into an adsorption tower bed, and the pressure of the passage is kept at 0.15MPa. Under the selective adsorption of the adsorption material, the carbon dioxide in the biogas is adsorbed by the adsorbent, while the unadsorbed methane will be discharged through the outlet and enter the gas storage bag. When CO is detected at the outlet of the adsorption tower 2 When the content is greater than 2%, it means that the adsorption tower will absorb CO 2 At this time, through program control, the biogas will be passed to the next adsorption tower for adsorption and separation, and the CO will be adsorbed 2 The saturated adsorption tower performs vacuum degassing operation, and the valve can be adjusted throug...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com