Micro oil cylinder

A kind of oil cylinder and miniature technology, applied in the direction of fluid pressure actuation device, etc., can solve the problems of high processing cost, long order cycle, complicated process, etc., and achieve the effect of low processing cost, high working reliability and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

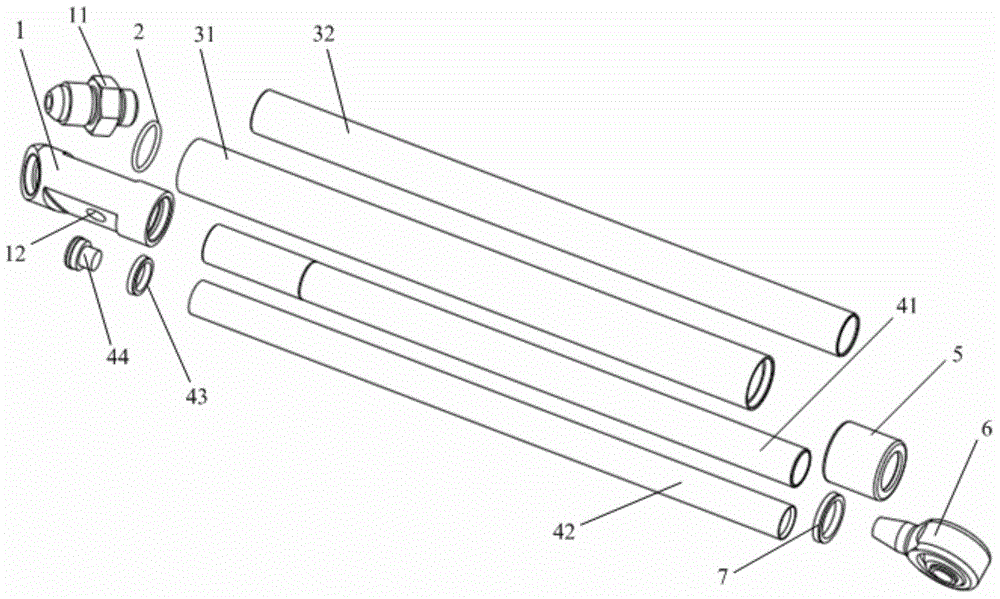

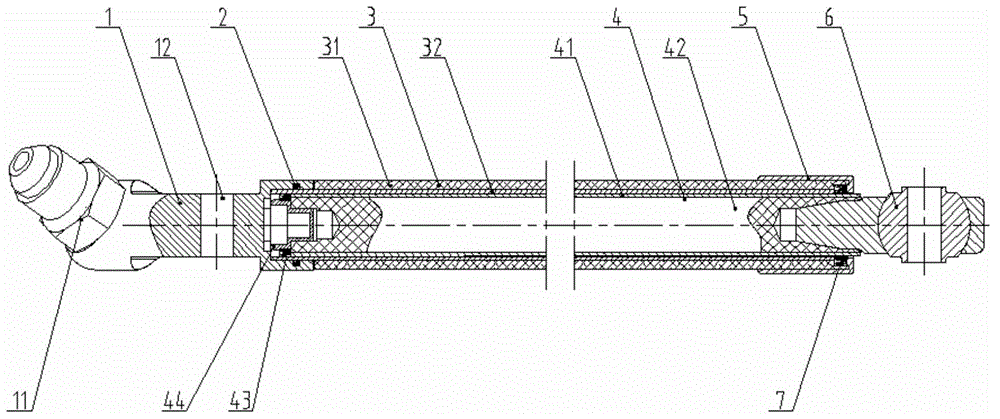

[0033] Such as Figure 1-Figure 3 As shown, the present embodiment provides a miniature oil cylinder, which mainly includes an end cover 1, a composite cylinder barrel 3, a composite plunger rod 4, a fixed end cover 5, and rod end bearings 6. The miniature oil cylinder is a single The action cylinder relies on the oil pressure to push the composite plunger rod 4 outward when it is loaded. After unloading, the composite plunger rod 4 is recovered to the inside of the composite cylinder 3 under the action of external force, thereby completing a working process.

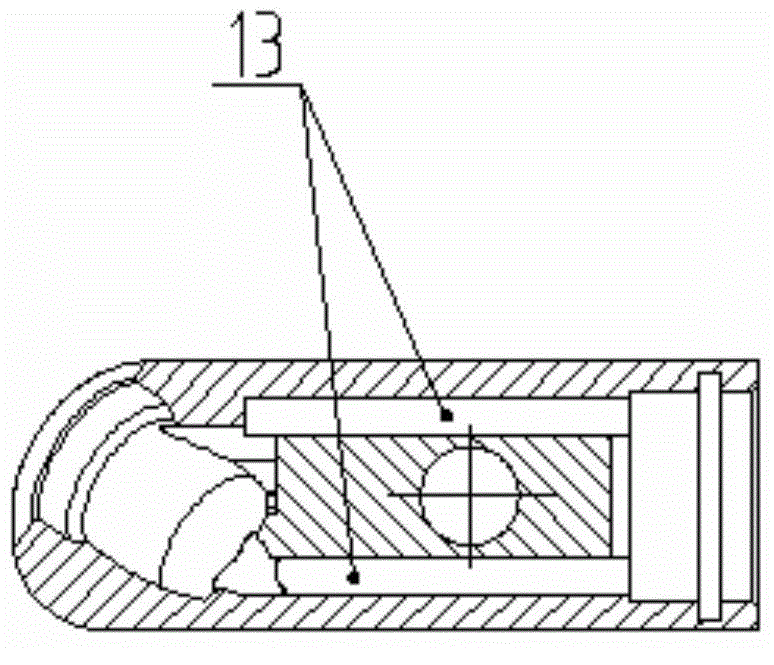

[0034] When loaded, the pressure oil of the hydraulic system enters from the joint 11 on the end cover 1, enters the rodless chamber of the miniature oil cylinder through the two oil passages 13 inside the end cover 1, and the pressure oil pushes the composite plunger rod 4 and the rod end bearing 6. Stretch out gradually along the inner wall of the composite cylinder 3 until the end point, and finally complete a stretc...

Embodiment 2

[0042] The miniature oil cylinder provided in this embodiment adopts new composite materials and new structural technology, and is mainly composed of end caps, composite cylinder barrels, composite plunger rods, fixed end caps, rod end bearings and related seals.

[0043] There are two oil passages, through holes and joints on the end cover, and the two inner oil passages are used for oil in and out, and the through hole left in the middle of the end cover is used to pass through the pin shaft to install and fix the miniature oil cylinder. The end cover is threadedly connected with the joint, and the installation joint surface is an inclined plane, which is designed to facilitate the installation and layout of the oil pipe. The joint is the only oil inlet and outlet port of the miniature oil cylinder; the composite cylinder is mainly composed of the cylinder casing and the cylinder , The cylinder casing is made of high-strength carbon fiber composite material, the cylinder is mad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com