Biomass fuel multi-backhaul combustor

A biomass fuel and burner technology, which is applied in the combustion, combustion method, combustion equipment and other directions of solid fuel, can solve the problem of not making scientific layout and improvement, and achieve the effect of ensuring the temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

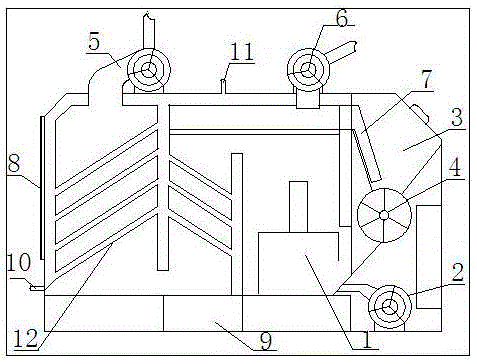

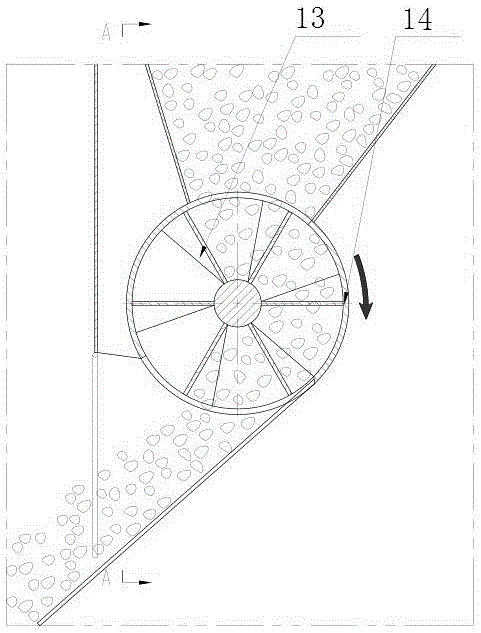

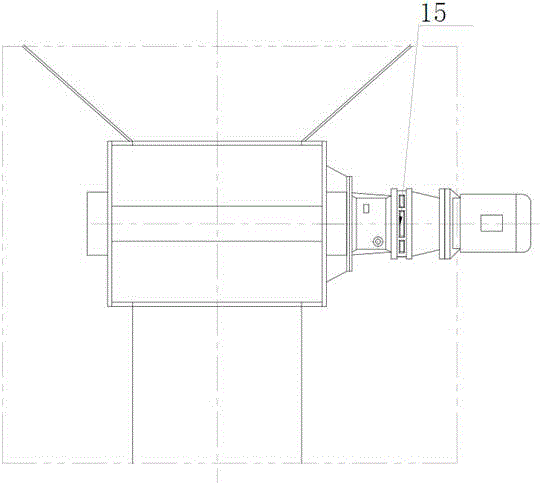

[0014] Accompanying drawing is a kind of specific embodiment of the present invention. This embodiment includes a combustion chamber and a heat exchange device 12 for its heat supply. The combustion system 1 is arranged in the combustion chamber, and the combustion system 1 is equipped with an ignition system 2. system) to feed the combustion system 1, the automatic feeding system includes a rotating blade 13 and a casing 14 that surrounds the rotating blade 13 and is adapted to the rotating blade 13, and the rotating blade 13 is connected with a driving device 15, and the driving device 15 Drive the rotating blade 13 to rotate, the flue gas generated by the combustion system 1 enters the exhaust system 5 and the hot air collection system 6 respectively through the heat exchange device 12, and the burner forms an S-shaped channel by setting partitions, and the flue gas passes through the S-shaped channel and passes through the exhaust system. The smoke system 5 is discharged f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com