Method for improving generation of nitrogen-containing volatile HCN from coal under oxygen/fuel combustion condition in CO2 atmosphere

A volatile matter and atmosphere technology, used in special forms of dry distillation, petroleum industry, coke ovens, etc., can solve the problem of lack of nitrogen-containing volatile matter, and achieve the effect of increasing the amount of production, the amount of HCN, and the catalytic effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

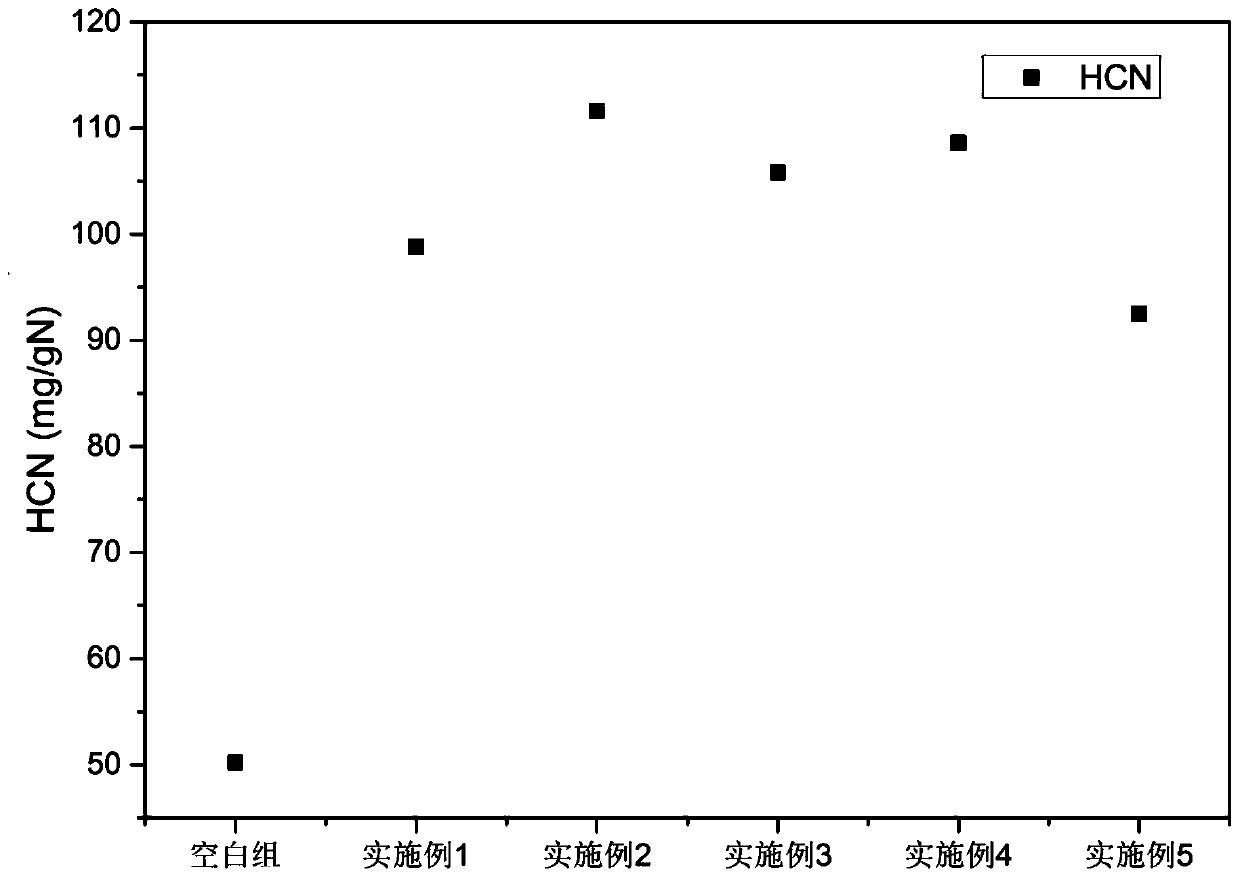

Examples

Embodiment 1

[0026] A way to improve coal in CO 2 A method for generating nitrogen-containing volatile matter HCN under oxygen / fuel combustion conditions of the atmosphere, the method comprising the following steps:

[0027] (1) Grinding and drying: pulverize the coal powder until the particle size is 100~120, and then dry it with gradient temperature rise to obtain dry fine coal powder. The gradient temperature rise program is as follows: under 0.3 atmospheric pressure, the temperature is raised from 20°C at a rate of 2°C / min After heating to 45°C for 1 hour, continue to raise the temperature from 45°C to 60°C at a rate of 5°C / min, and hold for 8 hours.

[0028] (2) Physical mixing: add a catalytic accelerator containing calcium hydroxide to the dry fine coal powder, the mass of calcium hydroxide in the catalytic accelerator is 1% of the dry fine coal powder, and stir evenly to obtain a pyrolysis standby sample; The catalytic accelerator includes 30 parts by weight of calcium hydroxide, ...

Embodiment 2

[0031] A way to improve coal in CO 2 A method for generating nitrogen-containing volatile matter HCN under oxygen / fuel combustion conditions of the atmosphere, the method comprising the following steps:

[0032](1) Grinding and drying: pulverize the pulverized coal until the particle size is 120~150, and then dry it with gradient temperature rise to obtain dry fine coal powder. The gradient temperature rise program is as follows: Under 0.6 atmospheric pressure, the temperature is raised from 20°C at a rate of 2°C / min After heating to 45°C for 3 hours, continue to raise the temperature from 45°C to 60°C at a rate of 5°C / min, and hold for 12 hours.

[0033] (2) Physical mixing: add a catalytic accelerator containing calcium hydroxide to the dry fine coal powder, the mass of calcium hydroxide in the catalytic accelerator is 3% of the dry fine coal powder, stir well to obtain a pyrolysis standby sample; The catalytic accelerator includes 45 parts by weight of calcium hydroxide, 2...

Embodiment 3

[0036] A way to improve coal in CO 2 A method for generating nitrogen-containing volatile matter HCN under oxygen / fuel combustion conditions of the atmosphere, the method comprising the following steps:

[0037] (1) Grinding and drying: pulverize the pulverized coal until the particle size is 100~200, and then dry it with gradient temperature rise to obtain dry fine coal powder. The gradient temperature rise program is as follows: under 0.5 atmospheric pressure, the temperature is raised from 20°C at a rate of 2°C / min After heating to 45°C for 2 hours, continue to raise the temperature from 45°C to 60°C at a rate of 5°C / min, and hold for 10 hours.

[0038] (2) Physical mixing: add a catalytic accelerator containing calcium hydroxide to the dry fine coal powder, the mass of calcium hydroxide in the catalytic accelerator is 2% of the dry fine coal powder, and stir well to obtain a pyrolysis standby sample; The catalytic accelerator includes 40 parts by weight of calcium hydroxi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com