Multichannel rotating type air preheater

An air preheater, rotary technology, applied in lighting and heating equipment, combustion methods, indirect carbon dioxide emission reduction, etc., can solve the problems of low utilization efficiency of flue gas waste heat, low workmanship, etc. The effect of reducing the circumferential deviation of smoke temperature and wind temperature and reducing the overall deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

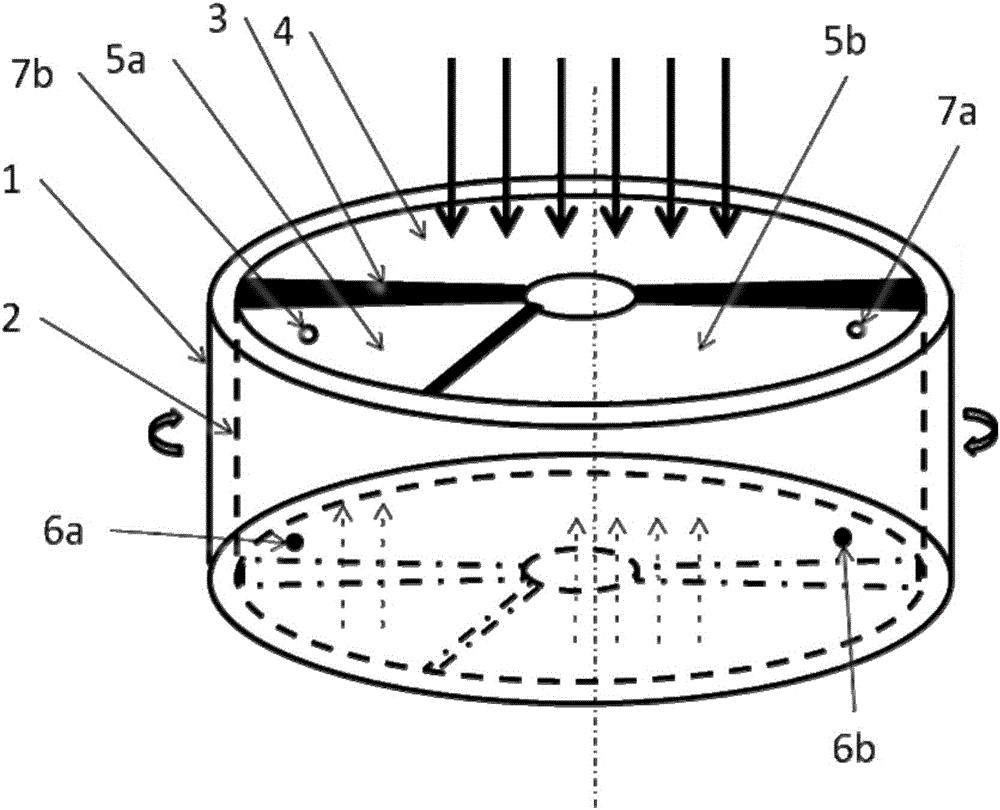

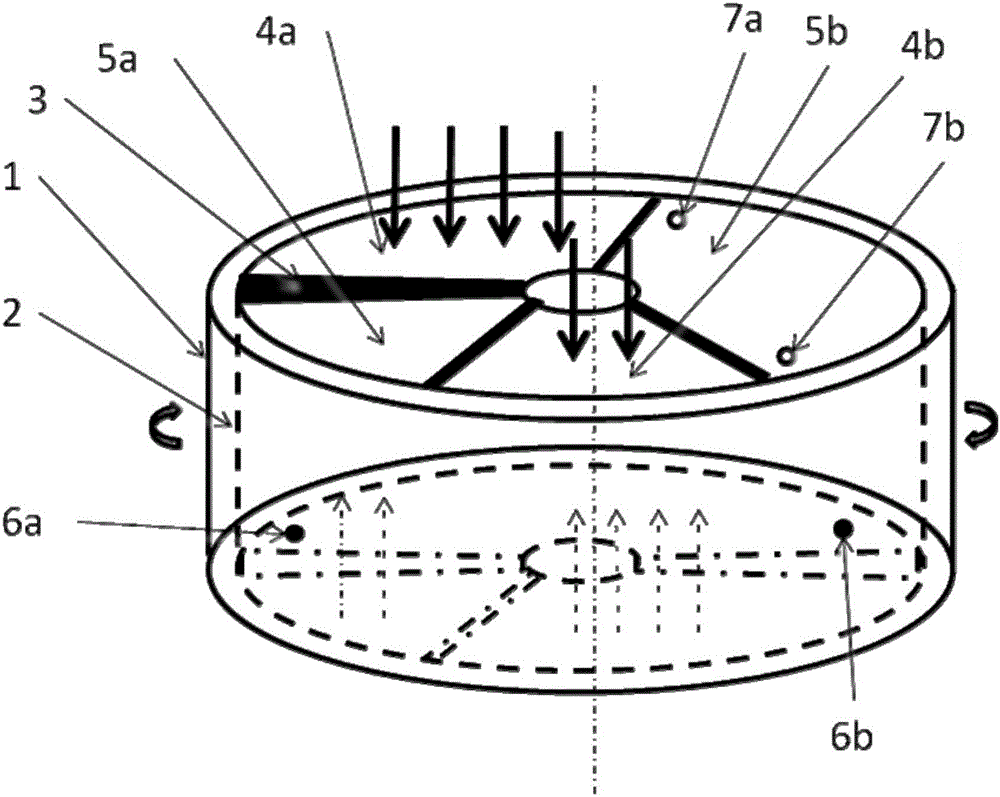

[0014] Working principle of the present invention, concrete structure and a kind of implementation method are further described below in conjunction with accompanying drawing:

[0015] The conventional air preheater has two air chambers, three chambers and four chambers and other structures. The two chambers have a channel for flue gas and air respectively; the three chambers are for the primary air and the secondary air to occupy two air channels separately. The flue gas only goes through one channel; one flue gas channel is still included in the four compartments, and the other three are the primary air channel, the secondary air channel and the fluidizing air channel (for circulating fluidized bed units). There is a sealing device at the direct dynamic and static gap of each channel.

[0016] figure 1 It is a schematic structural diagram of a conventional three-chamber rotary air preheater. Its basic structure includes an air preheater shell 1, a rotor 2 arranged in the sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com