Three-mode compound water chilling unit and control method thereof

A technology of water chiller and control method, which is applied in the direction of refrigerators, heating methods, refrigeration and liquefaction, etc. It can solve the problems of difficult oil return design of compressors, high requirements for booster devices, hindering heat transfer, etc., and achieves good application prospects , good energy-saving effect, small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in detail below through specific embodiments and in conjunction with the accompanying drawings.

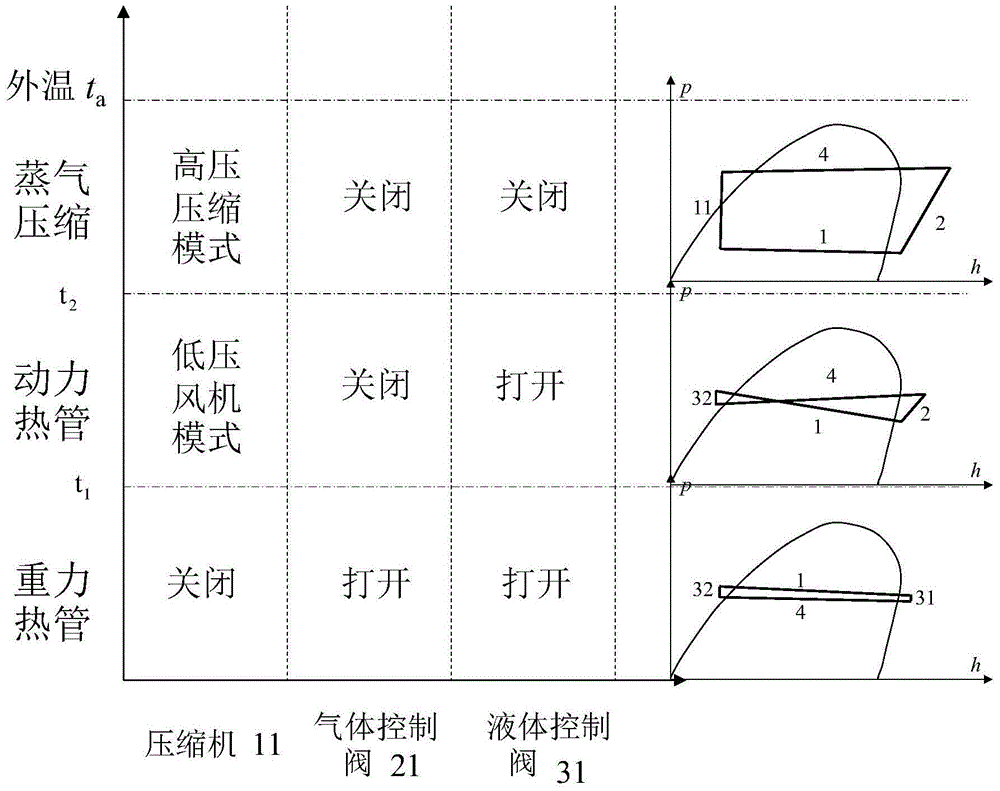

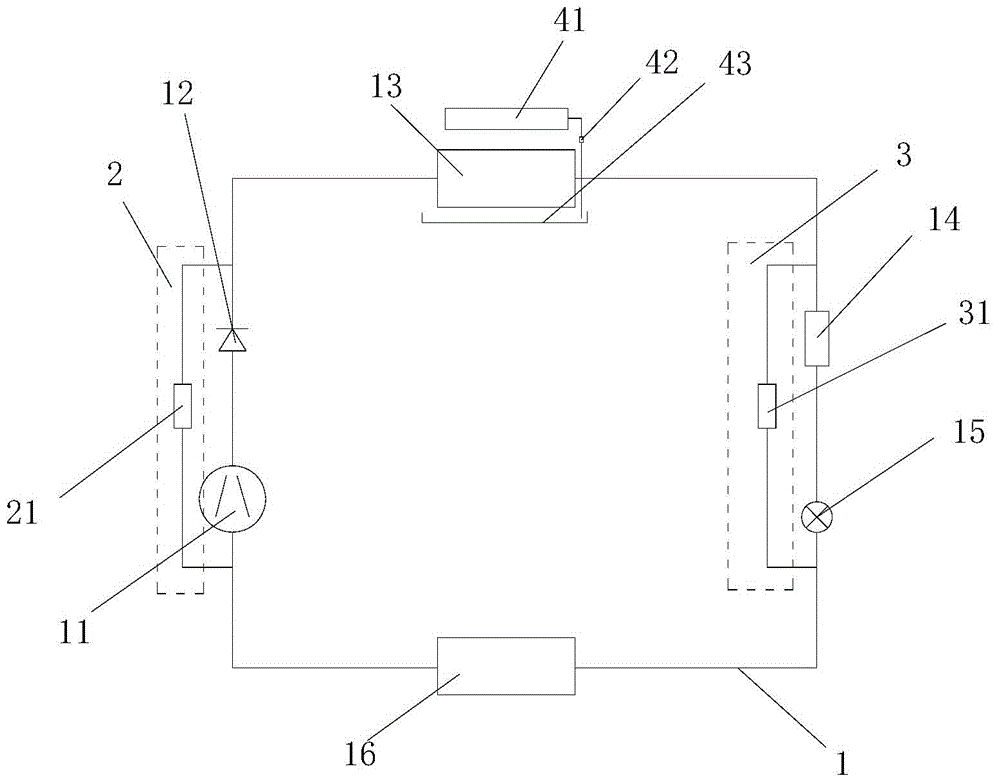

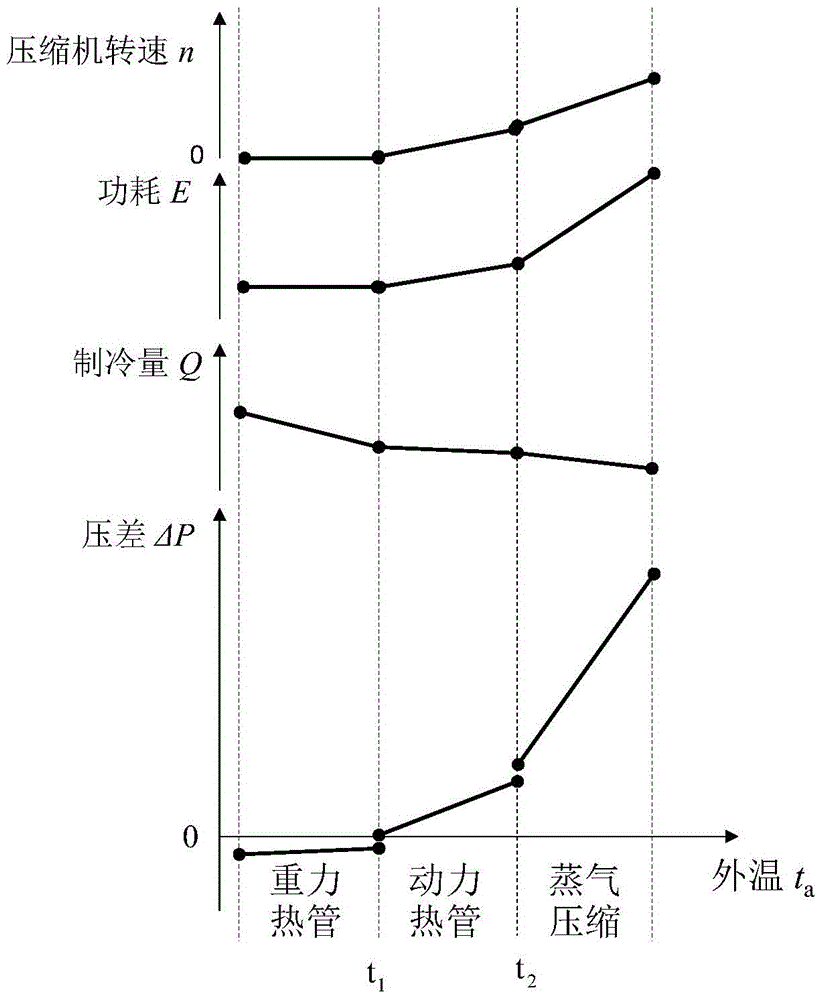

[0038] Such as figure 1 The shown three-mode composite chiller includes a compressor 11, a check valve 12, a condenser 13, a dry filter 14, a throttling device 15, an evaporator 16, and a gas bypass branch that are sequentially connected in series to form a refrigerant circuit 1 2 and liquid bypass branch 3, the level of the condenser 13 is higher than the level of the evaporator 16, the gas bypass branch 2 is provided with a gas control valve 21, and is connected in parallel with the compressor At the suction port of the machine 11 and the outlet of the one-way valve 12, the liquid bypass branch 3 is provided with a liquid control valve 31, which is connected in parallel with the inlet of the dry filter 14 and the outlet of the throttling device 15 . The compressor 11 is an oil-free DC frequency conversion magnetic levitation compr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com