Digital micro-mirror control method suitable for atomic fluorescence chromatic dispersion detection system

A technology of digital micromirror and atomic fluorescence, applied in fluorescence/phosphorescence, material excitation analysis, etc., can solve the problems of complex structure, slow detection speed, high price, etc., and achieve the effect of large data transmission and simplified methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

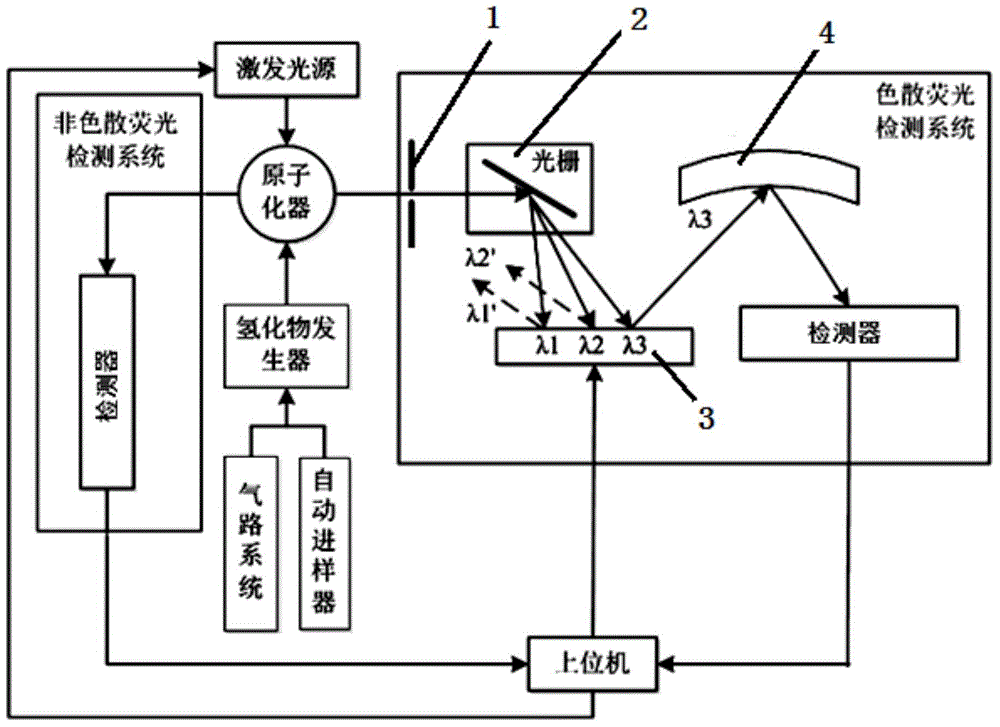

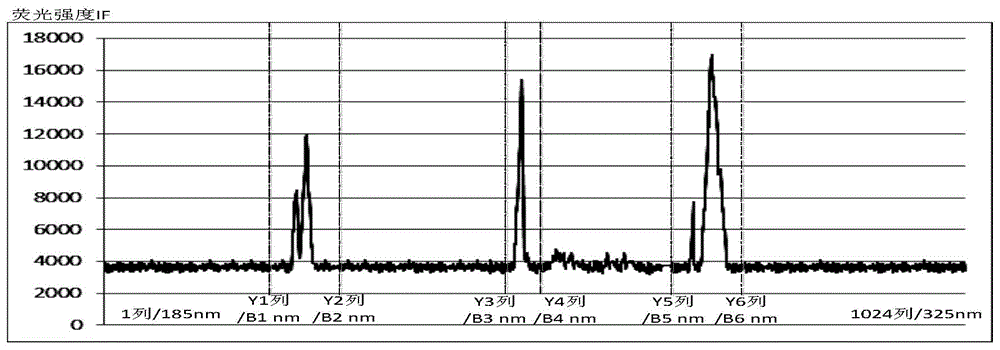

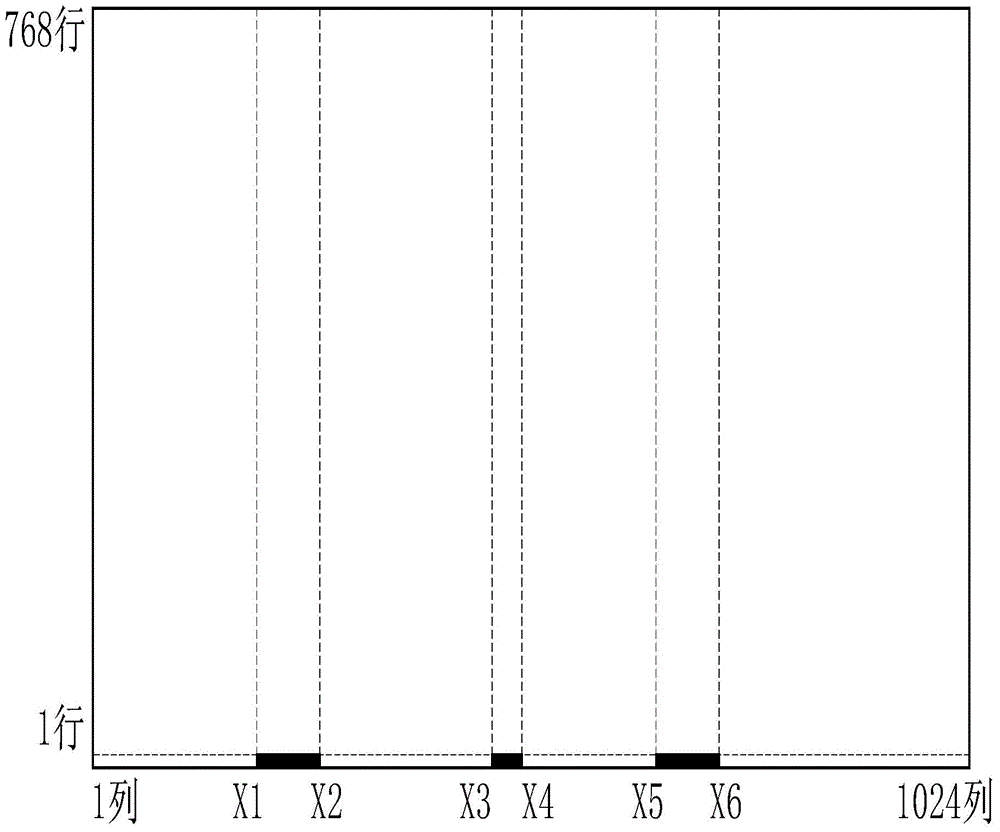

[0045] Such as figure 1 As shown, the prior art full-spectrum atomic fluorescence spectrometer based on a digital micromirror array includes a non-dispersive fluorescence detection system, a dispersive fluorescence detection system, and a host computer. Among them, the dispersive fluorescence detection system adopts a total reflection monochromator, and measures the spectral lines of different elements through digital micromirror technology to realize the full spectrum, multi-flux, and multi-information rapid detection of atomic fluorescence signals; the monochromator includes slit 1 and grating 2 , digital micromirror array 3, mirror 4 and detector. Its working principle is as follows: the light beam emitted by the excitation light source is focused on the atomizer to excite the atomic fluorescence, the fluorescent signal is first focused on the digital micromirror array through the slit and the grating, and the light signal reflected by the digital micromirror array is then ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com