Polarization-independent type photo-isolator and magneto-optical crystal device manufacturing method

A technology of magneto-optic crystals and optical isolators, which is applied in the fields of instruments, optics, nonlinear optics, etc., can solve the problems of not being able to use optical glue and increasing the insertion loss of optical isolators, and achieve the effect of reducing interface reflection and insertion loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

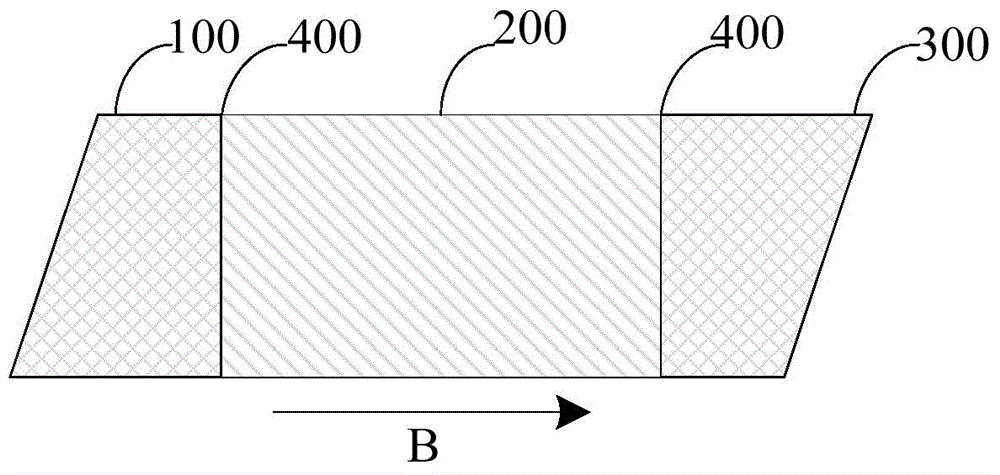

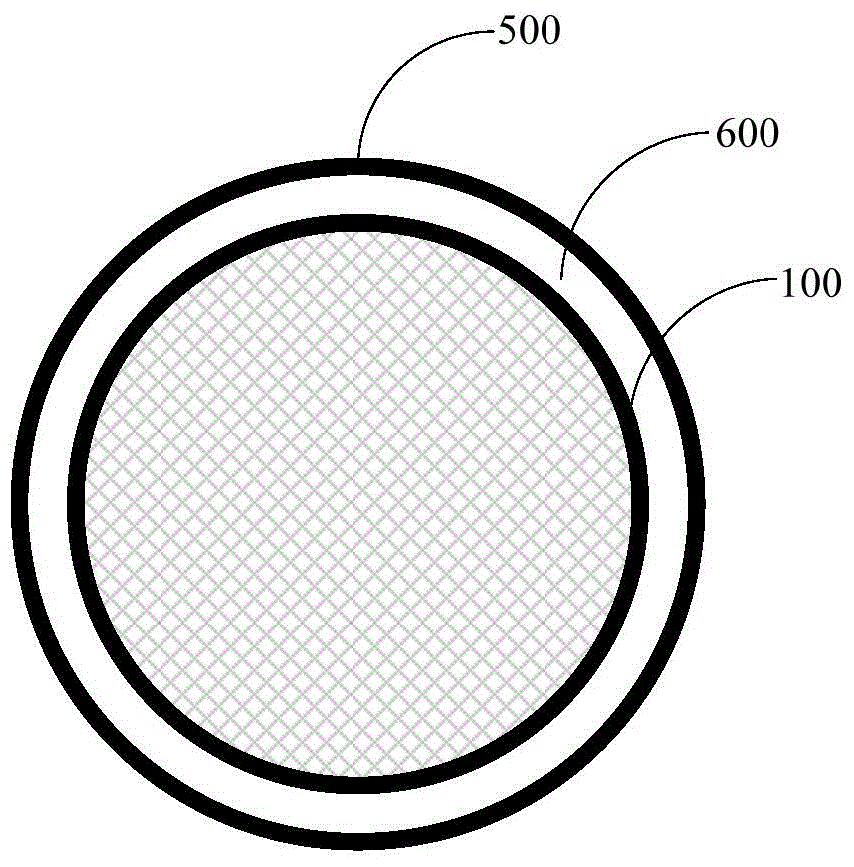

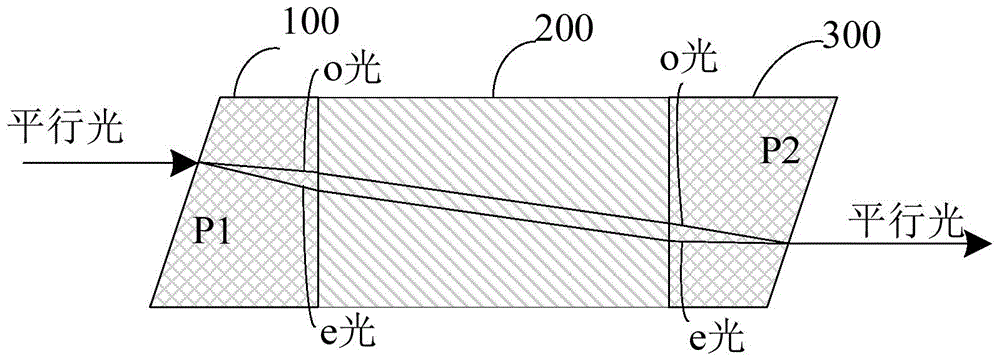

[0028] Such as figure 1 versus figure 2 As shown, the embodiment of the present invention provides a polarization-independent isolator, including: a first fiber collimator ( figure 1 Not shown in), the second optical fiber collimator ( figure 1 Not shown in), the magnetic ring, the first crystal wedge plate 100, the second crystal wedge plate 300 and the magneto-optical crystal device 200, the first crystal wedge plate 100 and the second crystal wedge plate 300 are made by photo-glue They are respectively fixed at both ends of the magneto-optical crystal device 200; the magnetic ring 500 surrounds the magneto-optical crystal device 200 to provide a stable magnetic field for the magneto-optical crystal device; the first fiber collimator is arranged on the first crystal wedge plate 100 One side; the second fiber collimator is arranged on the side of the second crystal wedge plate 300; wherein, the first fiber collimator and the second fiber collimator are arranged on the optical p...

Embodiment 2

[0033] In order to realize that the first crystal wedge plate 100 and the second crystal wedge plate 300 are respectively fixed to the two ends of the magneto-optical crystal device 200 by photoresist, the crystal axis clamps of the first crystal wedge plate and the second crystal wedge plate The angle is set to 45 degrees. Optionally, in the embodiment of the present invention, crystals of the same crystal space group are used to form the first crystal wedge plate, the second crystal wedge plate and the magneto-optical crystal device. For example, the first crystal wedge plate and the second crystal wedge plate use yttrium barium oxide (YVO 4 ) Crystal, magneto-optical crystal device adopts terbium vanadate (TbVO 4 ) Crystal or doped terbium vanadate (TbVO 4 ) Crystal made.

[0034] The embodiment of the present invention is made by using the crystals of the same crystal space group to realize the first crystal wedge, the second crystal wedge and the magneto-optical crystal devi...

Embodiment 3

[0040] In order to embody the superiority of a polarization-independent isolator provided by the present invention, an embodiment of the present invention also provides a method for manufacturing a magneto-optical crystal device, such as Figure 5 Shown, including:

[0041] Orient the magneto-optical crystal and determine the optical axis of the magneto-optical crystal;

[0042] Cut the magneto-optical crystal along the optical axis to form a long magneto-optical crystal;

[0043] Rounding the strip magneto-optical crystal to form a cylindrical magneto-optical crystal;

[0044] Both ends of the cylindrical magneto-optical crystal are optically polished and coated to form a magneto-optical crystal device.

[0045] Optionally, the magneto-optical crystal device is made of calcium terbium vanadate crystal.

[0046] Optionally, the magneto-optical crystal device has a diameter of 3-15 mm and a length of 8-50 mm.

[0047] In summary, the embodiments of the present invention provide a method f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com